In-Situ Cell Swelling Analysis System (SWE2110)

Brand: IEST

Product origin: Xiamen

Delivery time: About 6-8 weeks after placing the order

Supply capacity: About 20-40 sets/month

Introduction: SWE2110 adopts servo motor, combined with high-precision control system, equipped with multiple high-precision thickness measuring sensors, to accurately measure the expansion thickness and expansion force of the battery charging and discharging process.

Applications: Battery Material research and development and battery expansion mechanism analysis.

SWE Series Detailed Operation Video

Product Parameters

| Device Parameters | |

| Pressure measuring range | 10-1000kg |

| Pressure measuring resolution ratio/accuracy | 1kg±0.3% |

| Absolute thickness measuring range | 100mm |

| Absolute thickness measuring resolution ratio/accuracy | 1μm/±10μm |

| Relative thickness measuring range | ±5mm |

| Relative thickness measuring resolution ratio/accuracy | 0.1μm/±1μm |

| Temperature and humidity range | -20℃-80℃(SWE2100) |

| Measurable max pouch cell size | 220*180(If there is special size, it can be customized) |

| Installation Requirements | |

| Voltage | 220-240V/50-60HZ |

| Voltage variation tolerance | ±10% |

| Power dissipation | 3500W(SWE2100)、500W(SWE2110) |

| Environment temperature | 25±5℃ |

| Environmental humidity | Humidity <95%Rh at the temperature of 40℃ |

| Environmental magnetic field | Keep away from intense electromagnetic fields |

| Net weight | 330KG(SWE2100)、150KG(SWE2110) |

| Dimenstion | 600*1100*1800(SWE2100)、385*430*960(SWE2110) |

| Auxiliary Device | |

| Charge-dicharge device | Self-supply or provided by IEST |

| Computer | Self-supply or provided by IEST |

| Temperature Control | |

| SWE2100 | -20-80℃ |

| SWE2110 | none |

Advantages

1. In-situ non-destructive analysis of lithium detection innovative method.

2. A new method for in-situ expansion monitoring of multi-type cells.

3. Quantitative changes in cell expansion thickness and expansion force to facilitate research on cell expansion behavior.

4. The first in the industry, jointly developed with CATL and obtained the only authorization.

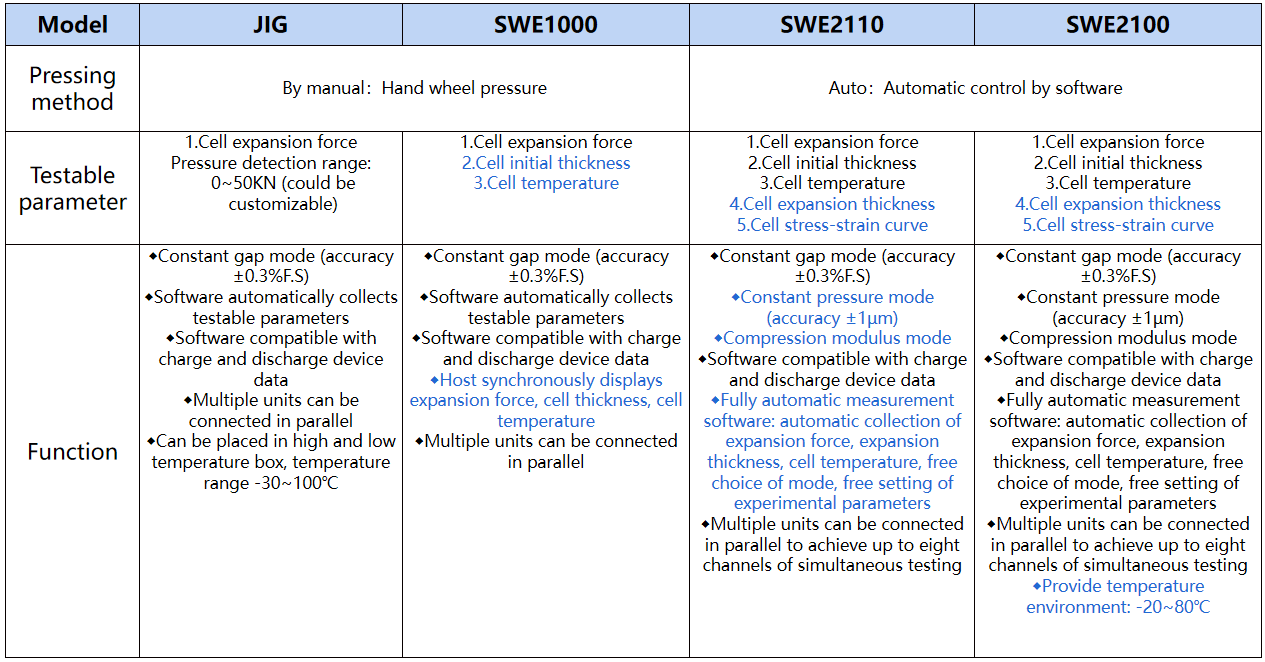

Different Models of SWE Series

Models of SWE Series

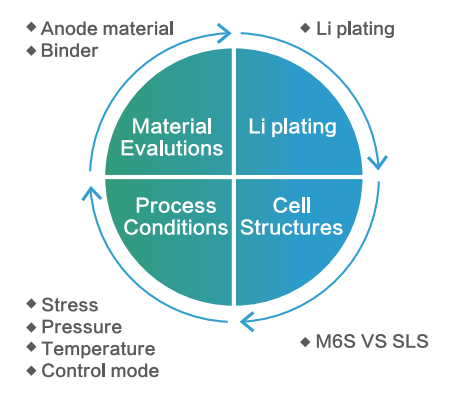

Why Use IEST SWE Series

1.During the charging and discharging process of lithium ions, as lithium ions are intercalated and extracted from the negative electrode, the cell will expand and contract.

2.The expansion behavior of the battery cell has become an important indicator for evaluating the reliability of the battery cell. During the design and production of the battery cell, the particle size, binder and pole piece structure of the negative electrode material must be pre-optimized.

3.The theoretical expansion ratio of next-generation high-energy-density anode materials, such as silicon and lithium metal, is much larger than that of graphite anode materials, so accurate and effective evaluation of the expansion behavior of the battery cell can effectively guide the installation design of the battery cell module.

4.The battery will also cause expansion changes when lithium is deposited, and at the same time it will cause a safety hazard in the use of the battery. Accurately determine the SOC window of the lithium analysis of the battery at different rates, and the fast charging technology of the battery, segmented the application of charging technology and other aspects has important guiding significance, helping battery design engineers to develop fast charging technology and optimize charging strategies.

5.IEST in-situ cell swelling analyzer is equipped with high-precision measurement sensors and mechanical sensors, which can be stable and accurate for a long time. It can simultaneously measure the expansion thickness and expansion force of the cell during charging and discharging, and can also perform non-destructive lithium analysis detection, realizing different modes of in-situ swelling tests during the charging and discharging process of the battery help R&D personnel to speed up the research on the expansion behavior of the battery, optimize the innovation of charging strategies and improve the efficiency of R&D.

Application

Client Companies Using IEST SWE Series