Description

1. Introduction

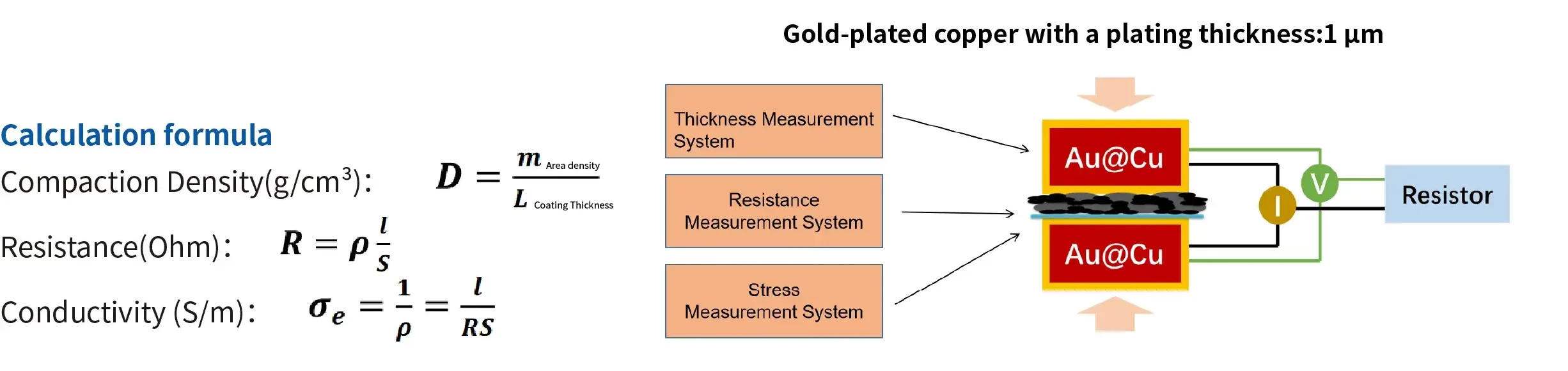

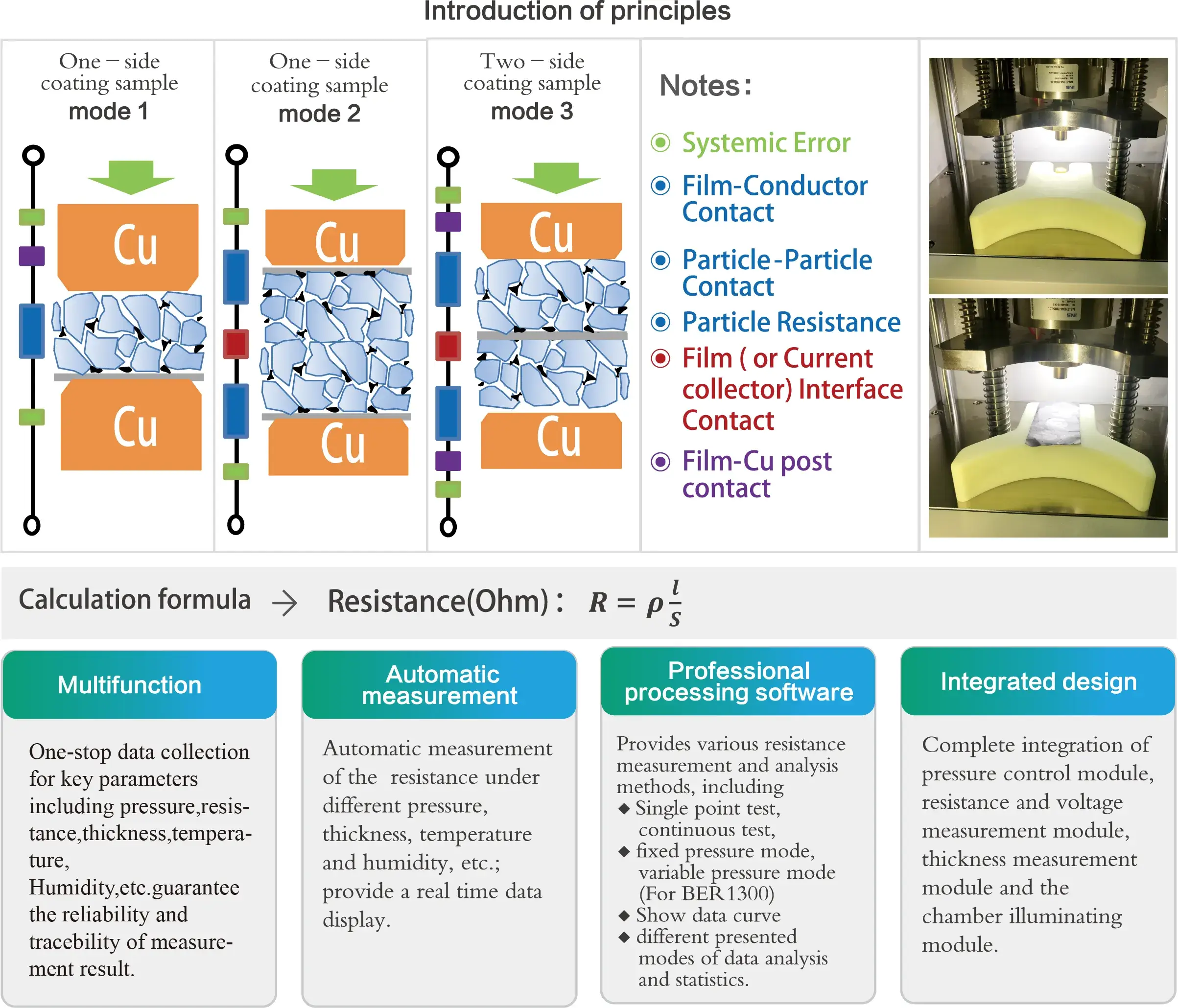

The BER Series Multifunctional Electrode Resistance Analyzer combines a high-precision pressure control system with integrated capabilities for electrode thickness measurement and resistance analysis. Using the double-sided controllable pressure disc electrode method, this electrode resistance analyzer directly measures the total through–thickness resistance of practical electrode samples, including coating resistance, coating–current collector contact resistance, and current collector resistance. It is an ideal tool for electrode formulation development and process stability monitoring.

Our Unique Testing Process:

- Comprehensive evaluation of slurry mixing homogeneity and coating stability, facilitating early detection of conductive agent agglomeration.

- Identification of mixing uniformity deviations in silicon-carbon composite anodes.、

- Assessment of electronic conductivity for different active material formulations.

- Evaluation of electronic conductivity across varied conductive agent formulations.

- Characterization of electronic conductivity in functional primer coatings for current collectors.

- Failure analysis of battery conductive networks.

- Contact resistance profiling of cathode/anode surfaces post-formation.

2. The Limitations of Traditional Test Methods

2.1 Current Status of Electrode Resistance Measurement

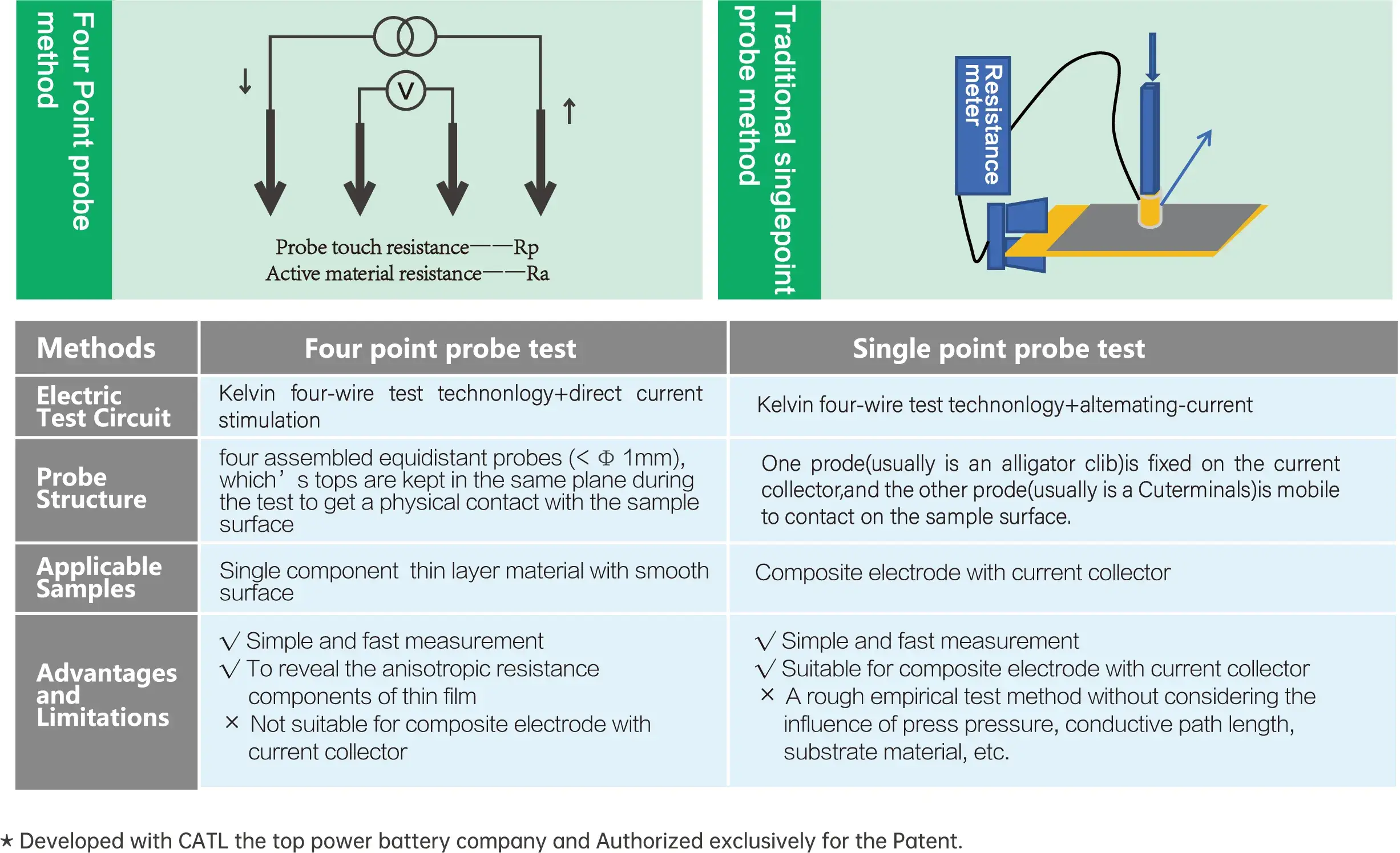

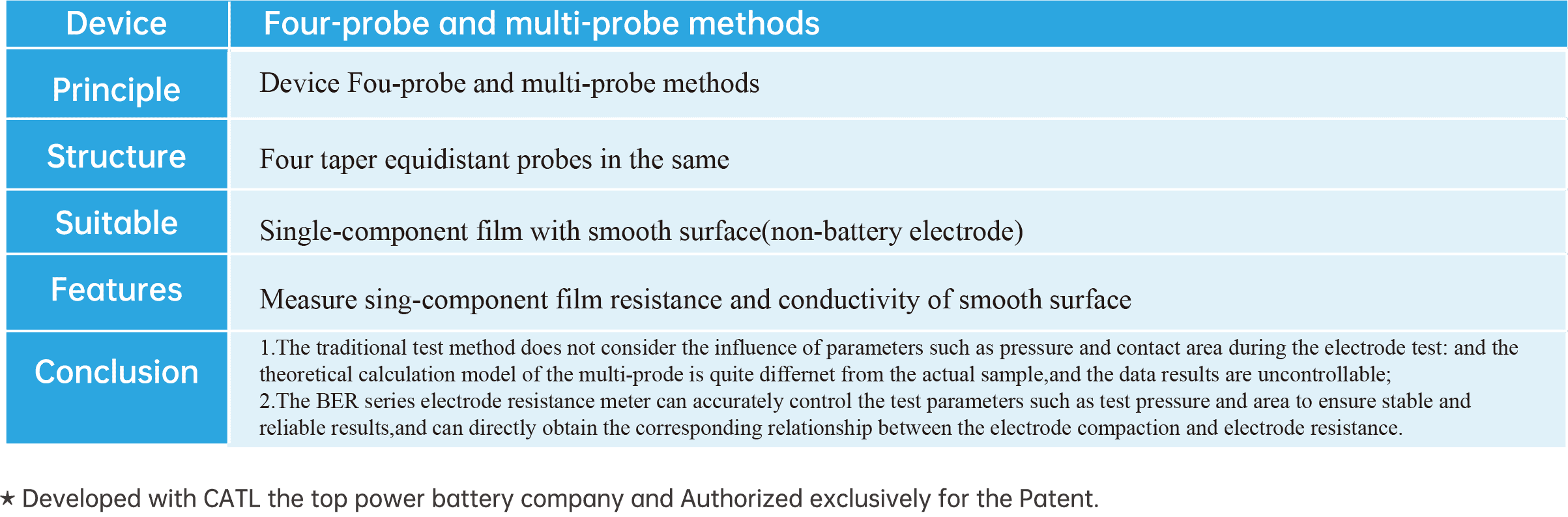

Multiple methods exist for measuring electrode resistance, including four point probe, multi-point probe, and single-point probe techniques. While these conventional approaches are well-established for homogeneous thin films in other fields, they exhibit significant limitations when evaluating composite electrodes for lithium-ion batteries.

2.2 Four-Point Probe Method

The four-point probe technique is a standard method for measuring thin-film surface resistance. Using four or more probe contacts, it provides accurate sheet-resistance measurements with simple operation. By applying basic equivalent-circuit models, the technique can separate anisotropic resistance components. When combined with electrode thickness measurement, four-point-probe data enable precise calculation of bulk resistivity and support comprehensive electrode characterization. However, its fundamental principle requires:

-

Smooth surfaces

-

Homogeneous materials

-

Insulating substrates

Lithium-ion battery electrodes present critical incompatibilities:

-

Inherently rough surfaces

-

Multi-component heterogeneity (active materials, binders, conductive additives)

-

Conductive current collector substrates

Consequently, four point probe measurements yield inconsistent data that defy theoretical modeling. Increasing probe quantity/complexity marginally improves reliability but introduces:

-

Structural impracticalities

-

Compromised measurement repeatability & reproducibility

2.3 Single-Point Probe Method

This industry-prevalent approach employs:

-

Fixed probe at current collector terminus

-

Mobile probe on electrode coating surface

Despite its simplicity (often implemented via user-assembled probes with resistance meters), it remains a rough empirical method neglecting critical variables:

-

Applied pressure consistency

-

Current path length variation

-

Substrate interference effects

Thus, single-point probing fails to deliver reliable or consistent electrode resistance data.

3. The IEST’s Creative Solution

As an leading electrode resistivity tests manufacturer, IEST Instrument presents the BER Series battery electrode resistance analyzer. The BER Series employs two pressure-controllable planar probes to directly measure through-thickness electrode resistance, which can obtain the overal resislance and resistivity in the thickness directon of the electrode, includimng the contact the collector and the current.

The dual-plane, pressure-controllable, high-conductivity probe specially designed for composite electrode and micron-level flat surface treatment ensure the measurement accuracy, the high-precision resistance resolution and the attached calibration module ensure the stability and reliability of the results.

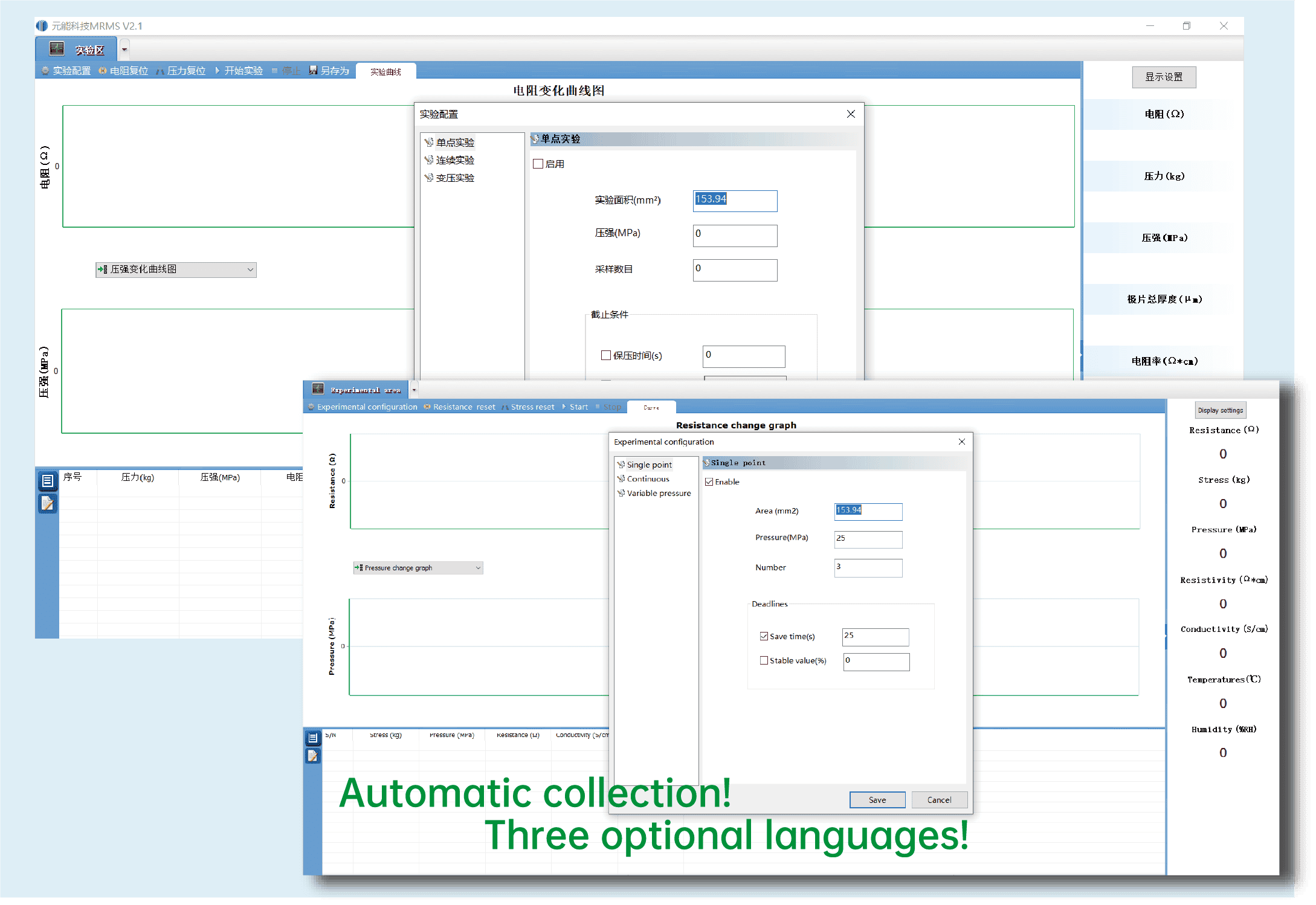

4. Software

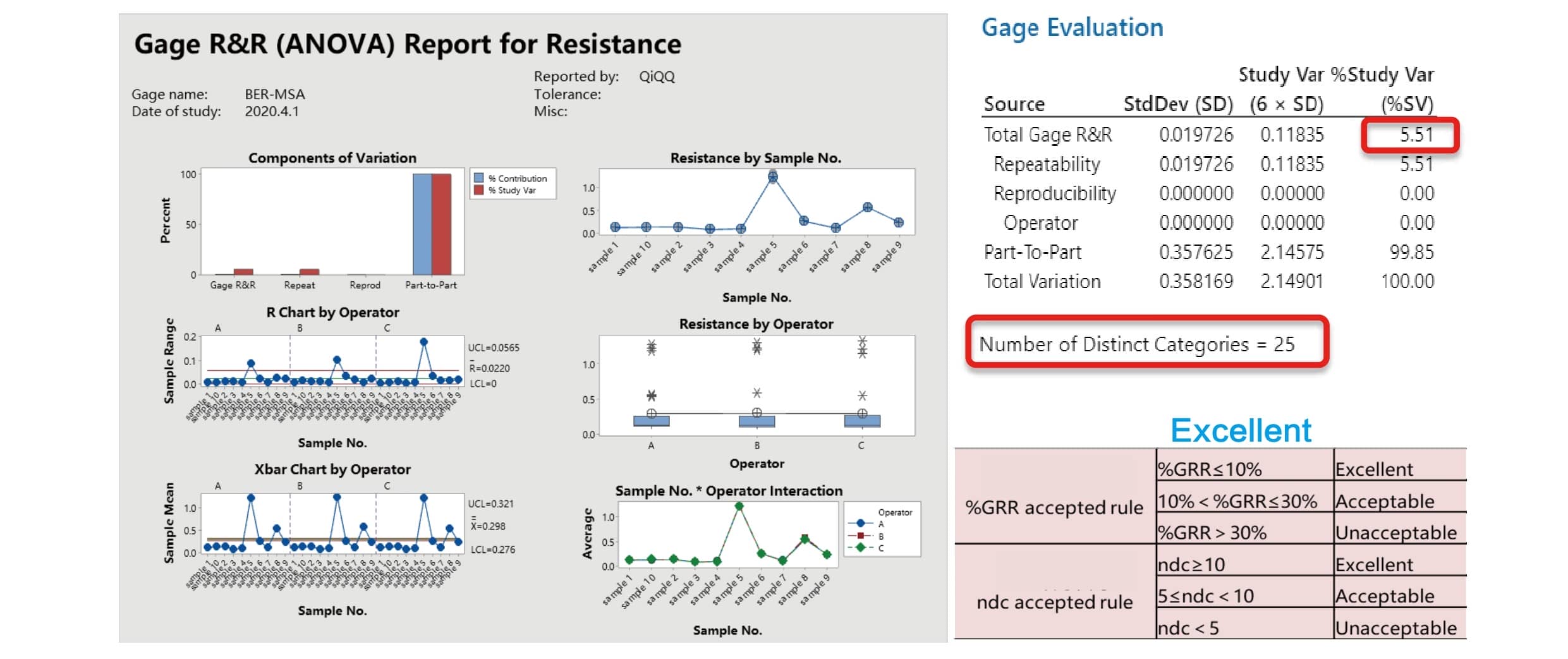

5. Measurement System Analyze

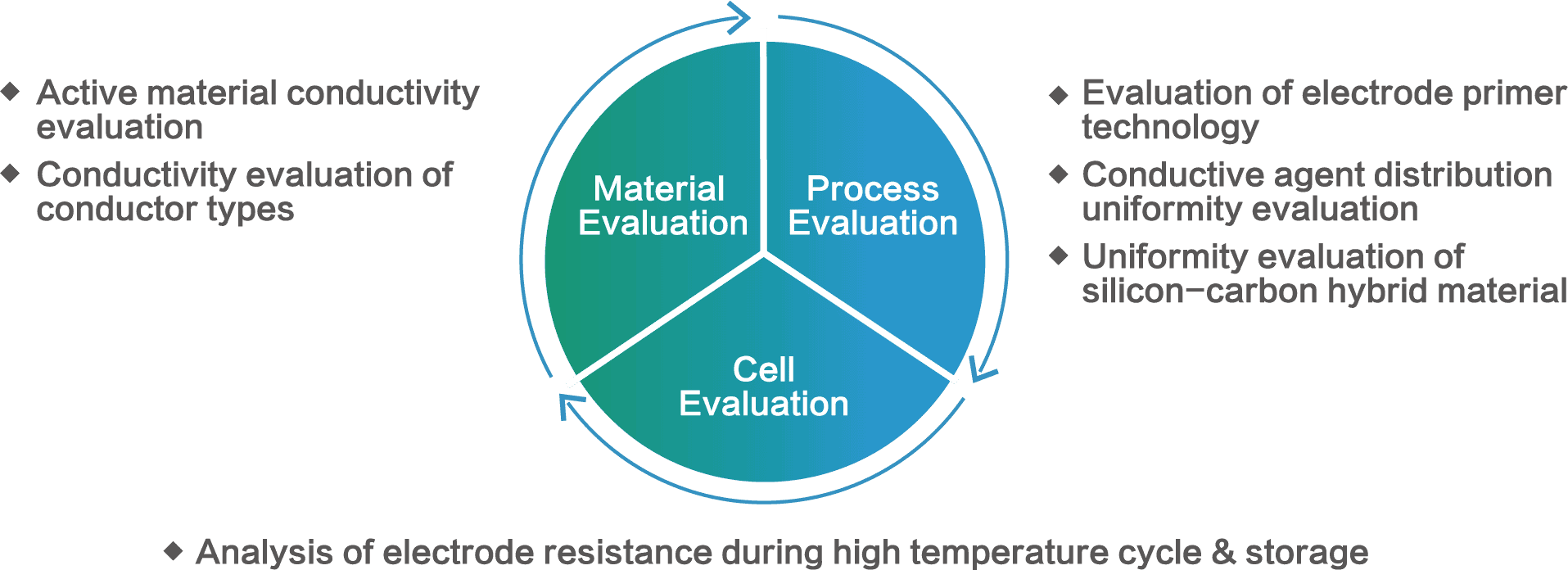

6. Applictions

Applications

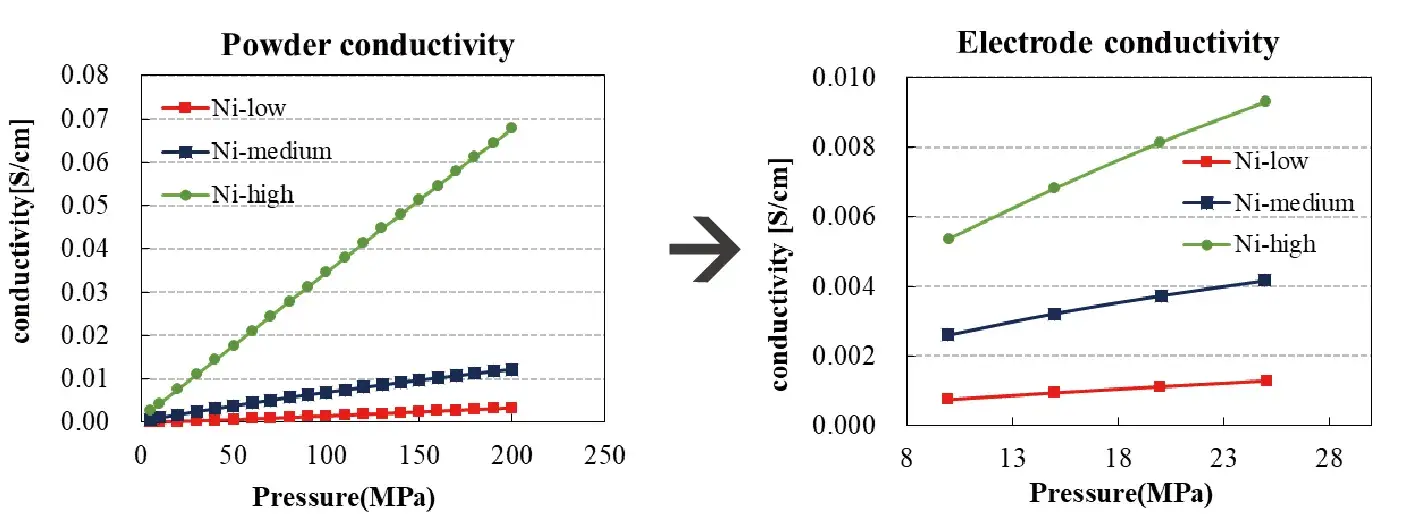

1. Evaluation of Active Materials: Modification of NCM Ternary Materials With Varying Nickel Content

Conclusion:

- Adjust the Ni content in the NCM material, and test the powder conductivity. It can be found that as the Ni content increases, the powder conductivity increases;

- Comparing three NCM pieces with different Ni content, it can also be obtained that as the Ni content increases, the conductivity of the electrode piece increases;

- Powder resistivity and electrode have the same trend!

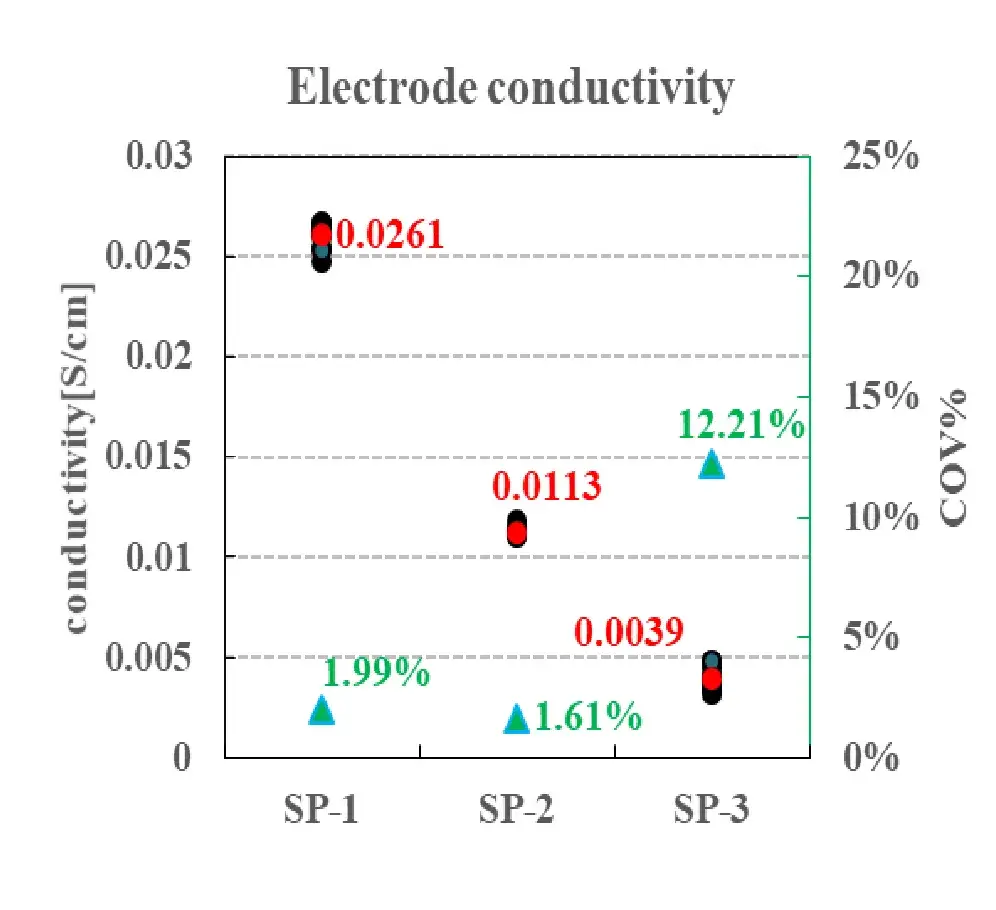

2. Evaluation of conductive agent types

(Note: Coefficient of Variation(COV)=(Standard Deviation SD/Mean)×100%)

Constant pressure test

- Pressure: 25MPa

- Holding time: 25s

- Points tested: 15 points

Conclusion:

-

Electrical conductivity ranking: SP-1 > SP-2 > SP-3

-

Dispersion homogeneity assessment: SP-3 shows higher coefficient of variation (COV) in conductivity, indicating inferior dispersion homogeneity. Both SP-1 and SP-2 exhibit superior dispersion performance

-

Electrode conductivity characterization can be applied to evaluate conductive agents’ electrical conduction and dispersion properties.

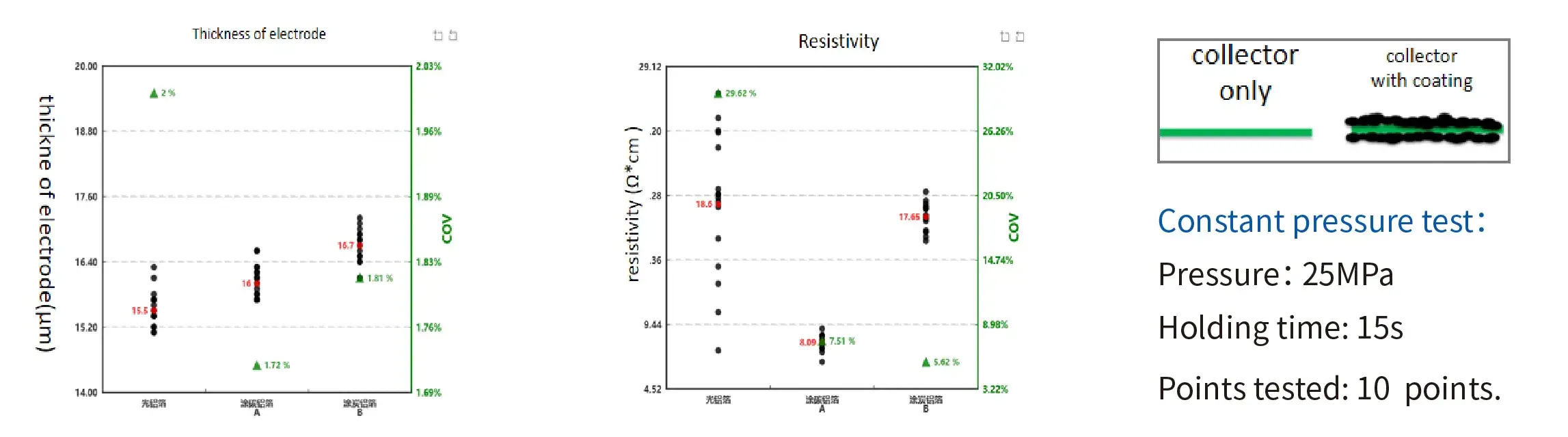

3. Evaluation of Primer Coated Aluminum foil: Pure aluminum foil, carbon coated aluminum foilA, carbon coated aluminum foil B

Conclusion:

- Different primer coating processes will change the conductivity of the current collector;

- After coating 1~2µm primer material on the aluminum foil, the conductivity uniformity of the current collector is better.

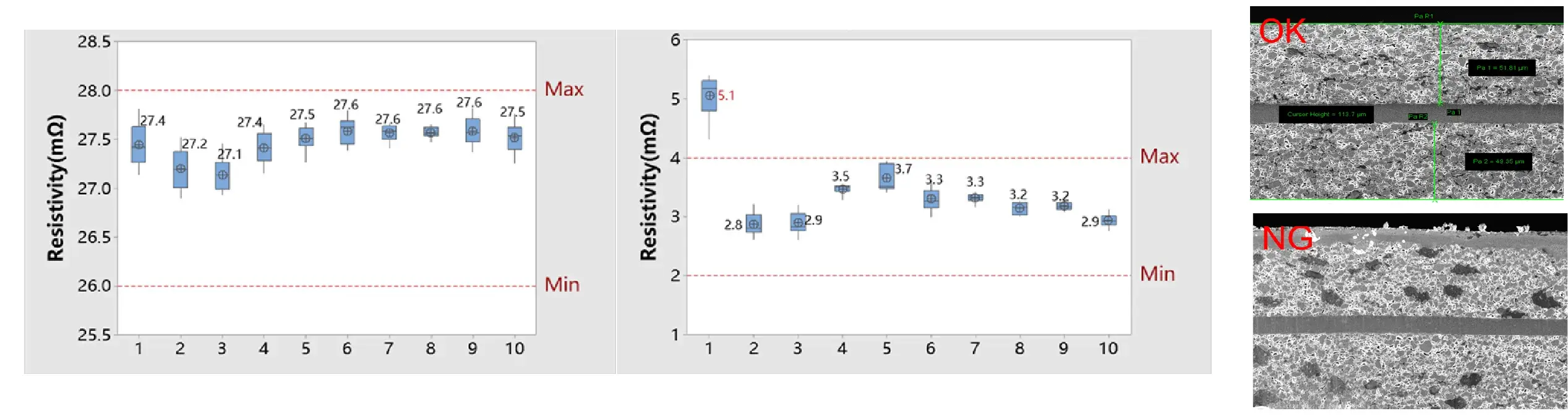

4. Stability Monitoring of Coating & Calendering Processes Across Batches

Conclusion:

- The dispersion homogeneity of conductive agents in electrodes is governed by complex process parameters including slurry formulation, mixing conditions, and coating/drying parameters. Non-uniform conductive agent distribution severely impairs cell kinetics, yet often remains undetected through conventional monitoring methods (e.g., visual inspection, adhesion strength) and is frequently overlooked, leading to irreversible performance degradation.

- Monitoring electrode resistance variations across production batches and spatial locations enables rapid detection of process variations at the electrode manufacturing stage.

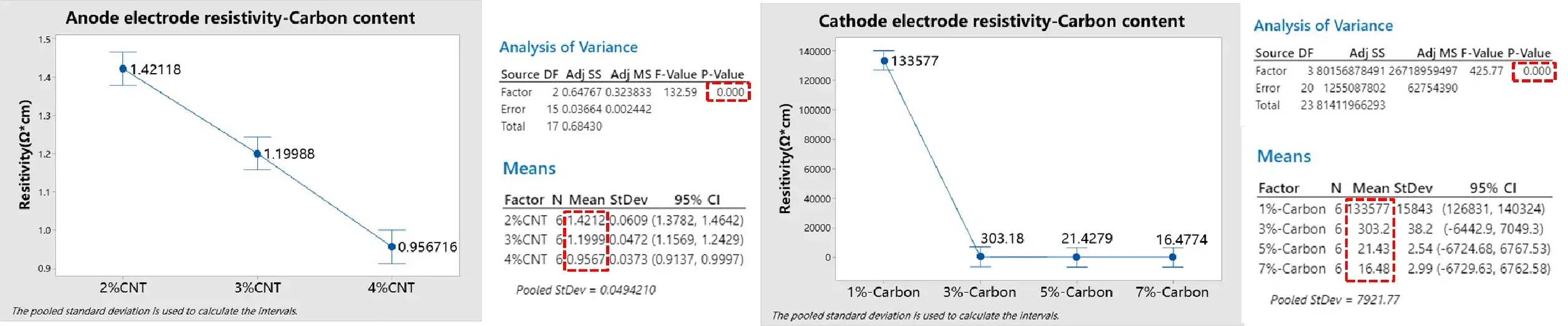

5. Cathode and Anode Electrodes with Different Conductive Agent Formulations

Conclusion:

- As conductive carbon content increases, the resistivity of NMC electrodes progressively decreases. When conductive carbon exceeds 5%, the reduction magnitude diminishes significantly. Conversely, graphite electrodes exhibit a near-linear reduction in resistivity.

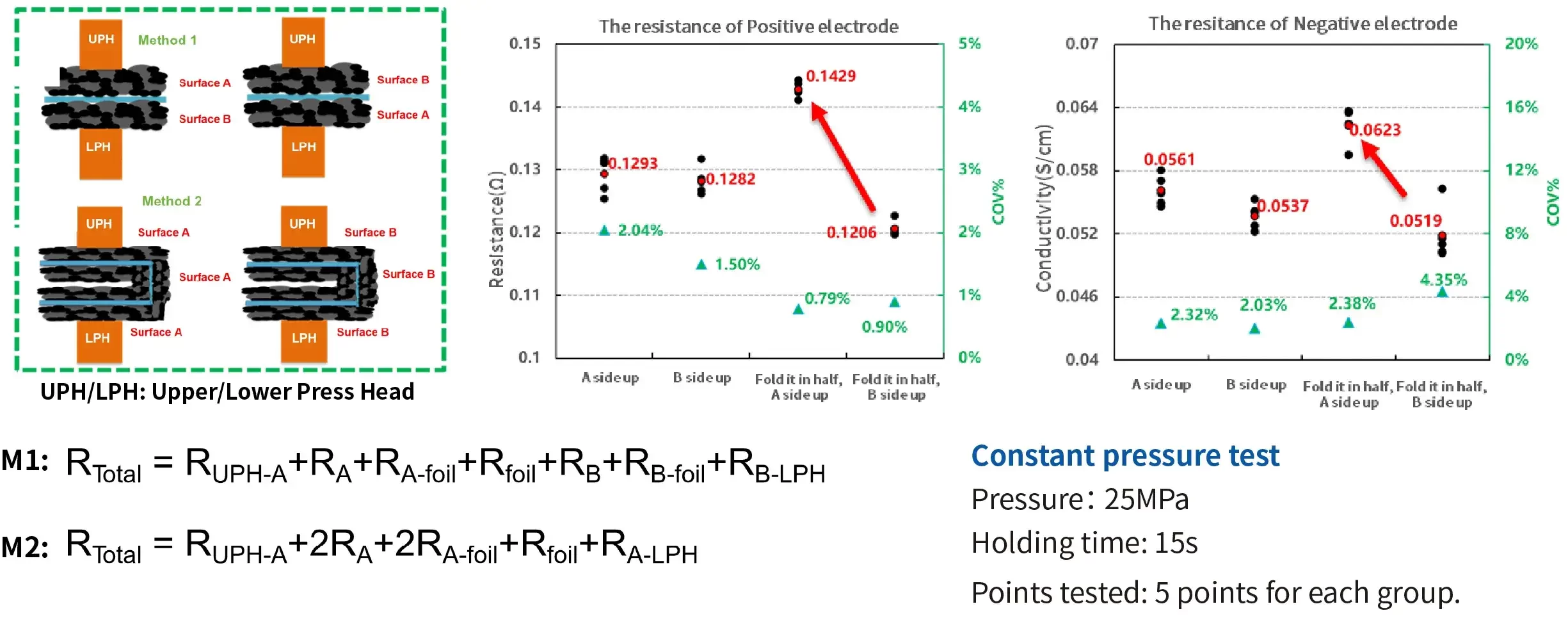

6. Separate the Resistivity of the A and B Coating Layers for the Double-coating Electrode

Conclusion:

- When the A side or the B side is facing up alone, he differencein the resistance and uniformity ofthe electrode sheet is smal:

- The diference between the A side and the B side after folding is mainly due to the difference in the coating on the two sides, so this method can be used to judge the difference in the coating on the AB side.

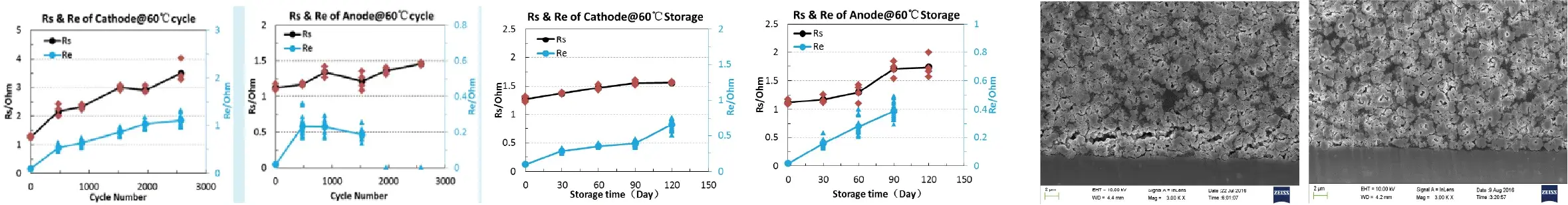

7. Anode/Cathode Electrode Changes During High-temperature Cycling & Storage

The resistance of the cathode continues to increase with the increase in the number of cycles, indicating that a large change has taken place on the cathode side after the high temperature cycle, which may be related to the byproducts on the surface of the cathode particles or the contact between the particles.

Conclusion:

- The resistance of cathode electrodes increases with the number of cycles.

- The resistance of anode electrodes increases with the storage time.

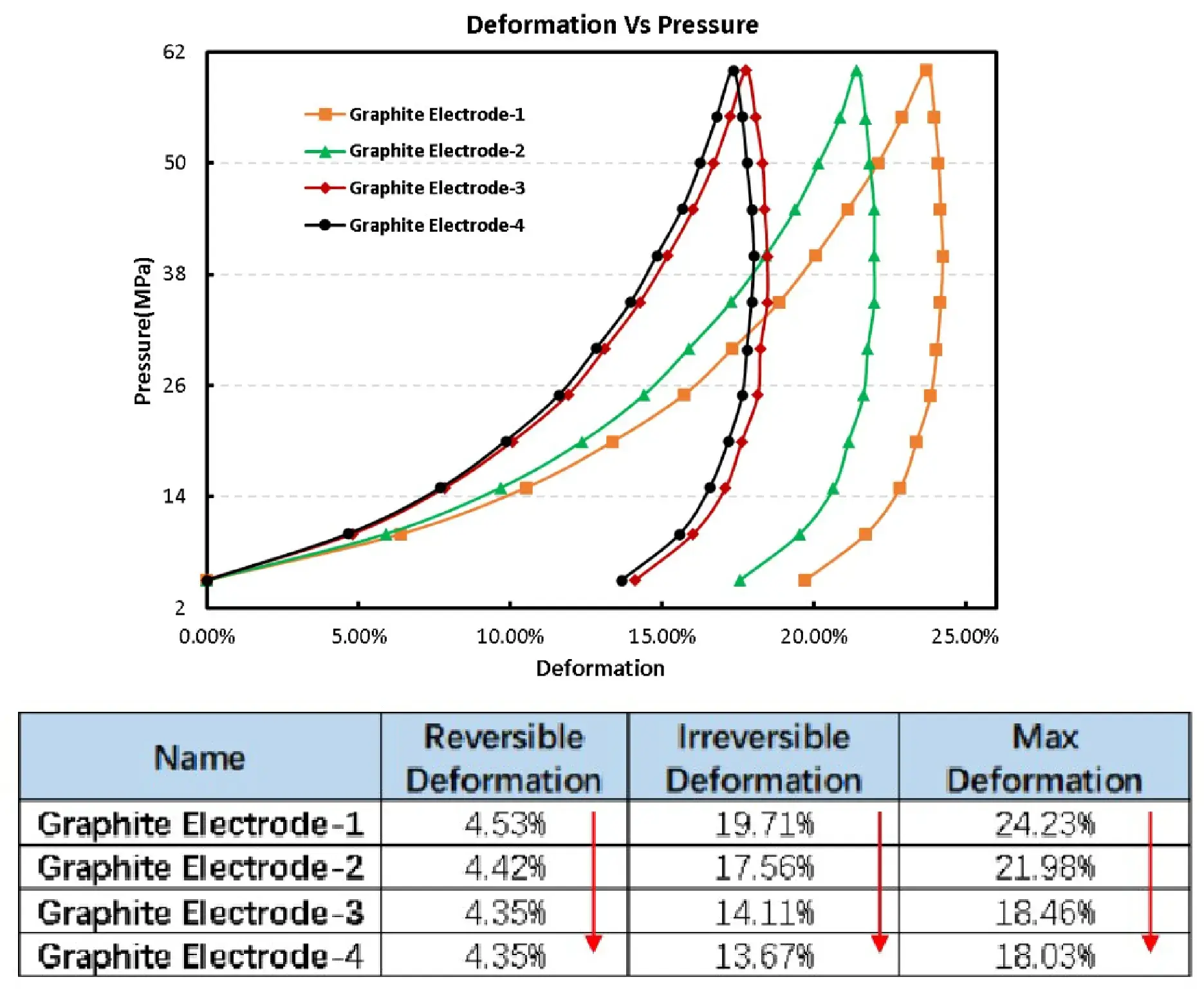

8. Characterization of Electrode Compressibility

Conclusion:

- 1(1.35g/cm³) < 2(1.50g/cm³) < 3(1.60g/cm³) < 4(1.65g/cm³)

-

Video