Battery Pressure Distrbution Measure System (BPD1000)

Brand: IEST

Product origin: Xiamen

Delivery time: About 6-8 weeks after placing the order

Supply capacity: About 20-40 sets/month

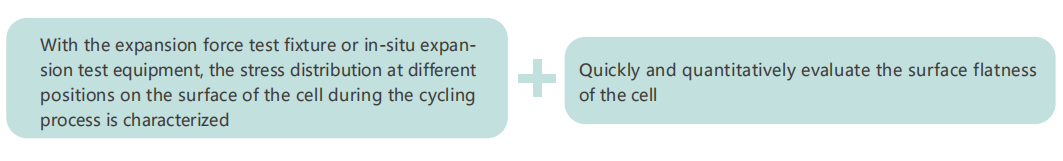

Introduction: It is used to quantitatively characterize the difference in stress distribution at different positions on the surface of the battery cell, and evaluate the performance of the battery cell.

Application: Expansion force distribution evaluation for soft cases, hard cases, modules, etc.

Model and Specification

| Model | BPD1000 |

| Sensor Film Size | 160*160mm(customized according to customer needs) |

| Pressure Range of Sensing Unit | 0-30kg(0~5MPa) |

| Pressure Rccuracy of Sensing Unit | ±10% FS |

| Sensing Unit Size | 7.5*7.5mm |

| Sensor Thicknessd | <0.3mm |

| Number of Sensors | 16X16 array layout, 256 sensors in total |

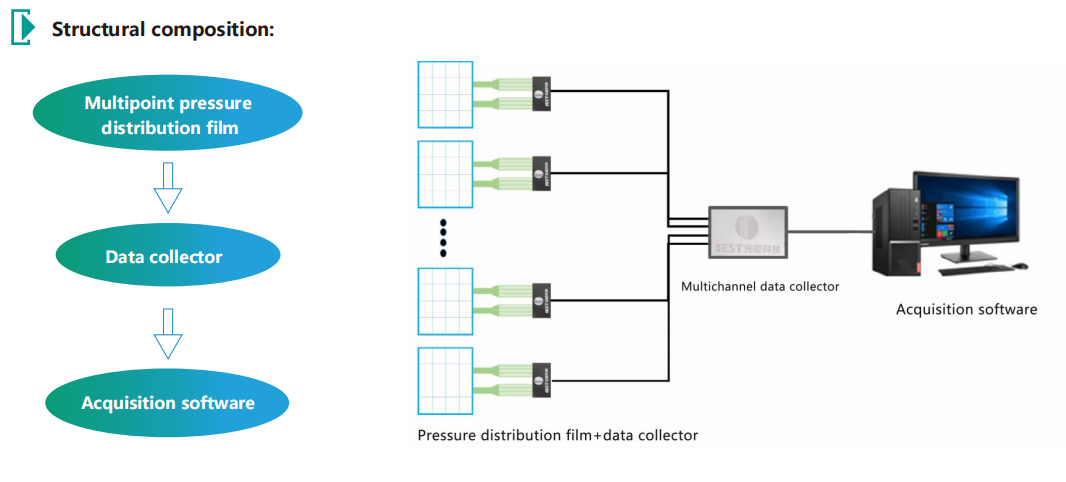

| Data Collector | 1 (sampling frequency<10Hz), size about 20 * 80 * 120mm |

| Software | 1 set |

Background

As a common electric energy storage device, lithium-ion battery (LIB) has the advantages of high energy density, high specific power, high output voltage, small self-discharge, long service life, etc.which is widely used in electric vehicles, electronic products and other fields. On the one hand, during the manufacturing process of the LIB, the internal stress distribution or the surface thickness distribution will be uneven because the process environment cannot be completely consistent; On the other hand, in the electrochemical cycle process, intercalation and deintercalation of Li-ions will lead to the volume expansion and contraction. However, the uneven current density or temperature distribution inside the LIB, will lead to the uneven distribution of the stress during the expansion of the LIB. Thus, the quantitative characterization of the stress distribution on the surface of LIB can provide a deeper perspective for the battery stress analysis, assist technicians to analyze the battery stress distribution, explore the causes of the failure of the LIB, and develop a safer and more reliable LIB.

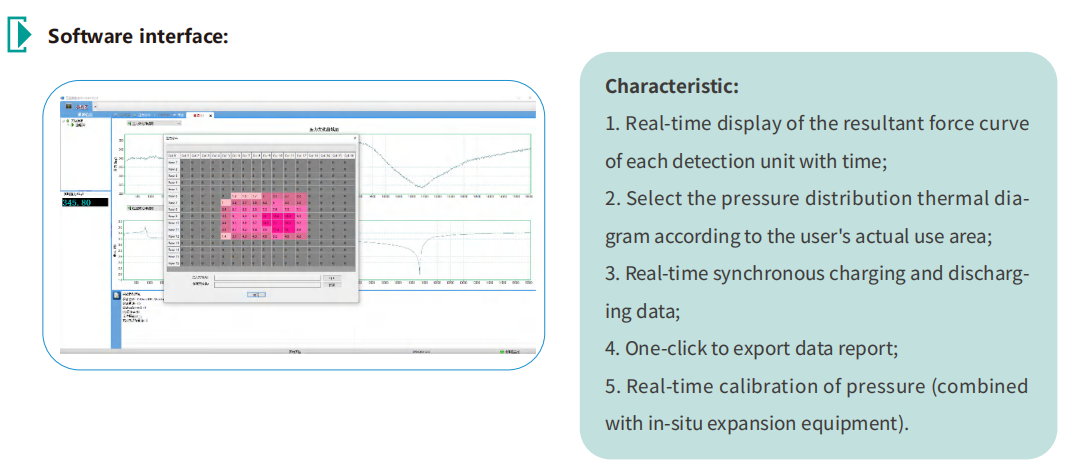

Introduction of Pressure Distribution Measure System

Application

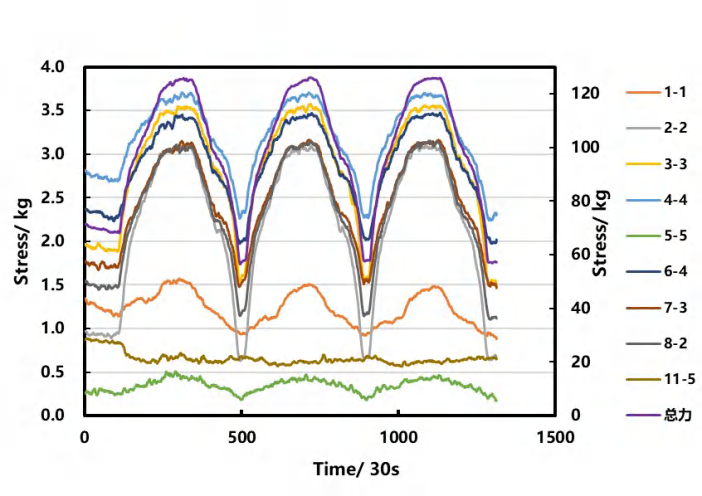

Application 1: Test of Stress Distribution on the Surface of the Cell During the Cycle

Test information: NCM-Graphite system, 3~4.3V, 0.5C, 50kg preload;

Result analysis: It can quantitatively characterize the difference of stress distribution on the surface of the cell, provide a deeper perspective for the stress analysis of the cell, and help technicians analyze the stress distribution in the cell, explore the causes of failure of the cell, and develop a safer and more reliable cell.

Application 2: Surface Flatness Test of Fresh Cell

Result Analysis: there is a certain correlation between the cell process design and the cell pressure distribution (flatness). Technicians can develop appropriate distribution standards through the pressure distribution system to monitor the batch stability of the delivered cells.

| Information of Cell | |||

| Cell 1 | Cell 2 | Cell 3 | |

| Cathode | NCM | LCO | LFP |

| Anode | Graphite | ||

| Capacity | 2000mAh | 4800mAh | 3000mAh |

| Model | 345877 | 456494 | 5778125 |

| SOC | 50% | ||