Compression And Conductivity Analysis of Silicon Carbon And Silicon Oxide Materials

Lithium-ion batteries have gradually been widely used in portable electronic products and electric vehicles due to their high energy density, long cycle life, environmental protection and other advantages. At present, the capacity of lithium-ion batteries with graphite materials as the negative electrode has gradually been unable to meet the requirements of long battery life of electric vehicles. Silicon-based materials are the most potential next-generation lithium-ion batteries due to their advantages of large specific capacity, low discharge platform, and abundant energy storage.

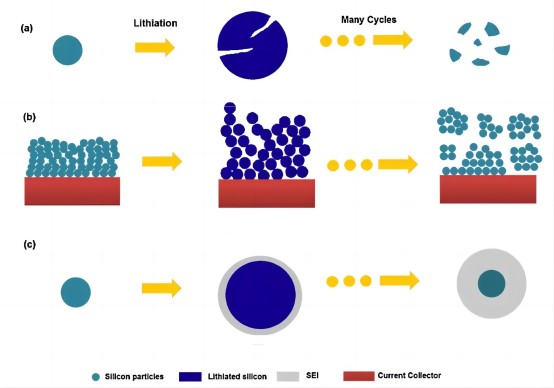

Battery anode material. However, the commercial application of silicon-based materials has been severely limited due to its own factors. First, the large volume change in the process of lithium deintercalation, which easily leads to particle pulverization, the separation of active materials from current collectors, and the continuous production of SEI films, which eventually lead to electrical The chemical properties decline, as shown in Figure 1 for the failure mechanism of silicon; in addition, the conductivity of silicon-based materials is relatively low, and the diffusion rate of lithium in silicon is relatively low, which is not conducive to the transport of lithium ions and electrons; for the existence of elemental silicon The volume expansion of silicon carbide leads to the problem of poor cycle stability.

At present, the main solutions are nanometerization and compounding. The practical application is mainly to improve its conductivity and lithium ion transport by doping with carbon materials or designing and modifying the structural ends of silicon materials. sex. This paper mainly combines silicon carbon materials with different doping ratios and siliceous oxide-based materials with different sintering processes, combined with scanning electron microscopy, powder conductivity, compaction density and other testing equipment , from the morphology, electronic conductivity, compaction density and compression. Systematic testing and analysis of materials in terms of performance.

Figure 1. Si electrode failure mechanism: (a) Material crushing; (b) Morphology and volume change of the whole Si electrode; (c) SEI continuous growth¹

1.Test Method

1.1 SEM Morphology Test of SiO Material and Si/C Material.

1.2 Use PRCD3100 (IEST) to test the conductivity, compaction density and compression performance of the material respectively.

The test equipment is shown in Figure 2 test parameters: the pressure range is 10~200MPa, the interval is 10MPa, and the pressure is maintained for 10s.

Figure 2. (a) Appearance of PRCD3100; (b) Structure of PRCD3100

2.Test Results

2.1 Silicon Carbon Anode Material

Among the new anode materials, the silicon anode has attracted extensive attention of researchers with its ultra-high theoretical specific capacity of 4200mAh/g; for the silicon anode, the huge volume expansion accompanying the charging and discharging process will generate large mechanical stress. , the active material is pulverized and loses contact with the current collector, resulting in the rapid decay of the reversible capacity of the electrode. In this experiment, the silicon content of 3% (SiC-1), 6% (SiC-2), 10% (SiC-3 ) of three silicon-carbon hybrid materials to test the differences in their electronic conductivity, compaction density and compressive properties.

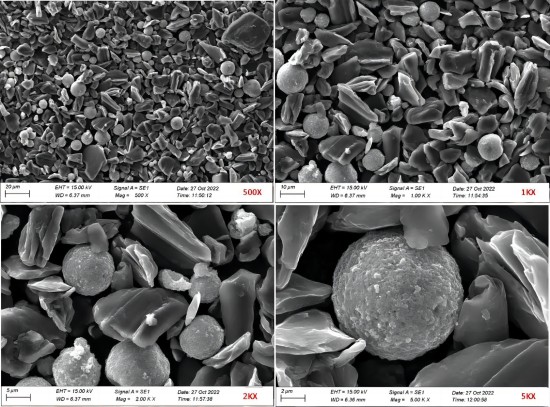

Combined with scanning electron microscope, the differences in morphology test of the three materials were compared respectively. Because the silicon content of the three materials is not high, and the difference in sample preparation is involved, no obvious difference can be seen under the electron microscope. Figure 3 shows the SEM morphology images under different magnifications under 6% silicon content, in which the morphology of the silicon material is mostly spherical, and the particle size is 5-10 μm. The expansion cracking of silicon particles is often related to the size of the particles. Generally speaking, the cracking of larger-sized μm-sized silicon particles is more serious, while the nano-sized particles smaller than a certain critical value will have fewer cracks. The best way to use μm-sized Si particles is to composite them with graphite.

Figure 3. SEM images of the same silicon-carbon hybrid material at different magnifications

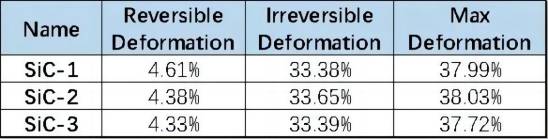

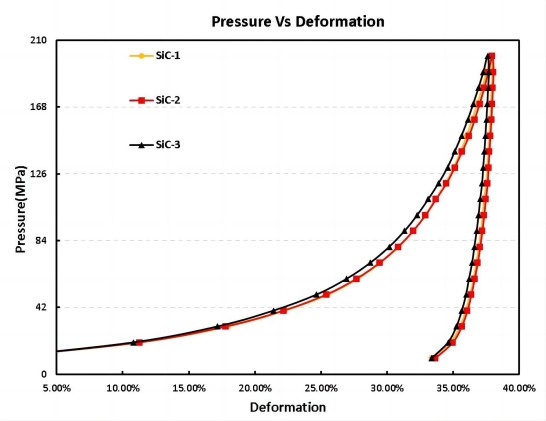

In order to further evaluate the difference of mixed materials with different silicon content, this part uses PRCD series powder resistivity and compaction density dual-function equipment to evaluate the electrical conductivity, compaction density and compressive performance, as shown in Figure 4 and Table 1 for the three materials respectively Compared with the stress-strain curve and the deformation situation, the elastic and plastic deformation of the three materials are not very different from the perspective of the deformation ratio, which shows that the addition of a small amount of silicon spheres has little effect on the overall deformation of the carbon material.

Table 1. Summary of deformation data of three silicon and carbon hybrid materials

Figure 4. Stress-strain curves of three silicon-carbon hybrid materials

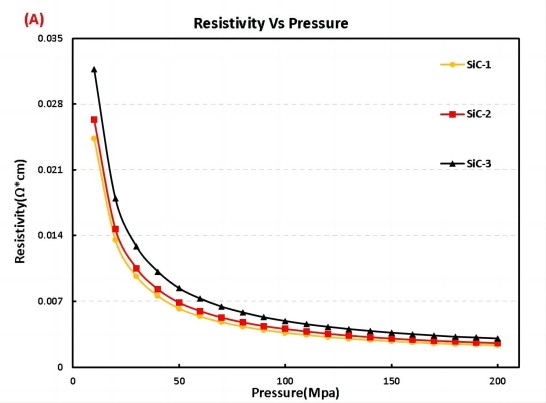

Figure 5 shows the measurement results of the resistivity and compaction density of the three materials as a function of pressure. It can be seen from Figure (A) that with the increase of the proportion of silicon, the conductivity of the mixed material gradually deteriorates, which is mainly due to Because the conductivity of silicon material is poor, as its proportion increases, the overall performance of the hybrid material deteriorates. As for the measurement results of the compaction density of the three materials (B), it can be seen that with the increase of the proportion of silicon material, the compaction density has a significantly smaller trend, which is mainly because the compaction density of silicon material is relatively The carbon material is relatively small, and will change significantly in the mixed material with the difference in the proportion of the materials.

Therefore, the design and preparation of the pole piece of the silicon-carbon composite negative electrode needs to optimize the electrode parameters such as the conductive agent formulation and the compaction density of the pole piece. The research shows that compared with the graphite anode, the silicon carbon anode appropriately reduces the compaction density and increases the porosity, which is beneficial to buffer the volume expansion of silicon particles and inhibit the generation of cracks. On the one hand, the conductive agent uses a zero-dimensional conductive agent to coat the active particles to form a compact short-range electronic conduction network, while a one-dimensional conductive agent such as CNT is used to form a long-range electronic conduction network from the current collector to the entire thickness of the electrode.

Figure 5. (A) and (B) are the changes of resistivity and compaction density of three silicon and carbon mixed materials with pressure, respectively

2.2 Silica-based Anode Material

Compared with elemental silicon, the siliceous oxide-based composite reacts during the first lithium intercalation process to generate Li2O, Li₄SiO₄ and Si in situ, of which Li2O and Li₄SiO₄ are electrochemically inert components and do not participate in subsequent electrochemical reactions. The elemental Si is uniformly dispersed with each other, which buffers the volume expansion of elemental Si during the charge and discharge process to a large extent, and improves the cycle stability of the overall electrode material.

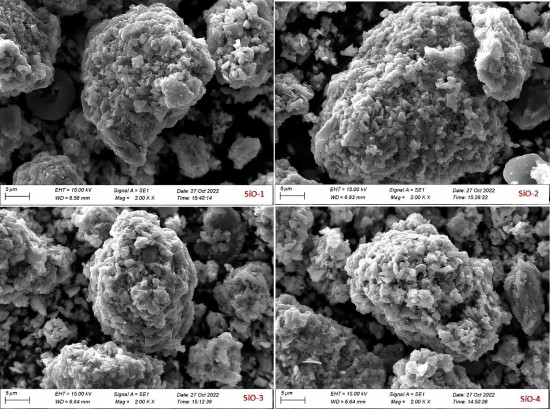

However, siliceous oxide-based materials still have an expansion effect in the process of lithium deintercalation, which leads to the problem of capacity decay and poor electrical conductivity. Modified application. This part selects four siliceous oxide-based materials SiO-1, SiO-2, SiO-3, SiO-4 coated with 0.1% carbon on the surface at different sintering temperatures (material sintering temperature: SiO-1 < SiO-2 <SiO-3<SiO-4), measured and analyzed from the perspectives of SEM morphology, electrical conductivity, compaction density, and compressive properties. Figure 6 shows the comparison of the differences in the morphology test of the four materials. From the morphology results, there is no obvious difference between the four materials. Compared with the elemental silicon material, the siliceous oxide-based material exhibits irregular surface loose morphology.

Figure 6. SEM morphologies of four SiO-based materials

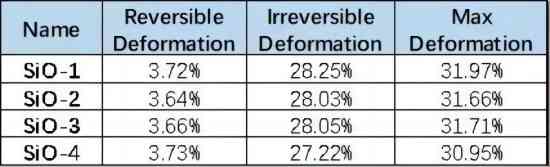

Similarly, for silica-based materials, comparative test evaluations were carried out in terms of compressive properties. As shown in Figure 7 and Table 2, the stress-strain curves and deformation conditions of the four materials are compared. From the perspective of the deformation ratio, for the four materials with different sintering temperatures, the overall compressive properties of the SiO-2 and SiO-3 materials are The difference is not big, but the maximum deformation of the two materials, SiO-1 with the lowest sintering temperature and SiO-4 with the highest sintering temperature, is significantly different. The preliminary judgment may be that with the increase of sintering temperature, the overall density of the material is better. , the compression resistance of the material increases. From the data that characterizes the plastic deformation parameters of the material, that is, irreversible deformation, the SiO-4 material with a higher sintering temperature has the smallest plastic deformation, while the elastic deformation and reversible deformation under the action of material stress have little overall difference from the data. However, in the actual compression process of powder particles, multi-gravity acts together, and stress is also a process of comprehensive change, which can be further analyzed in combination with other testing methods.

Table 2. Summary of deformation data for four SiO2-based materials

Figure 7. Stress-strain curves of four SiO2-based materials

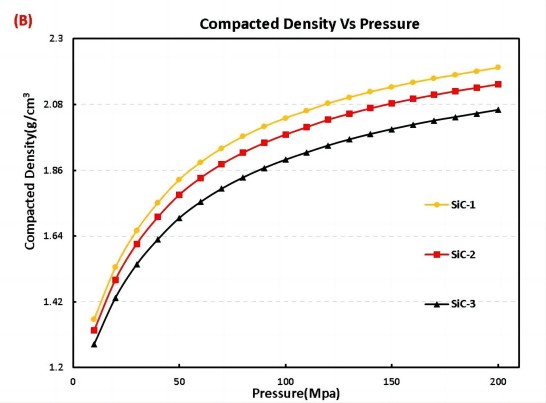

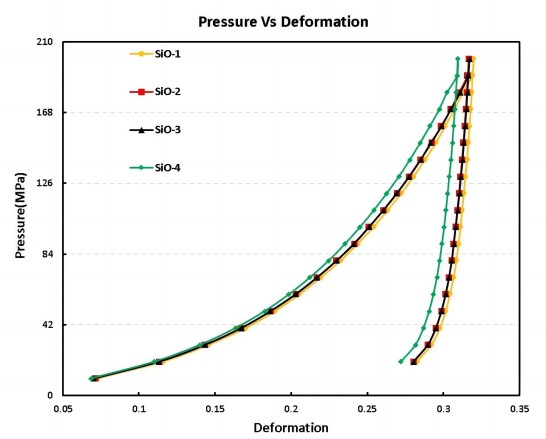

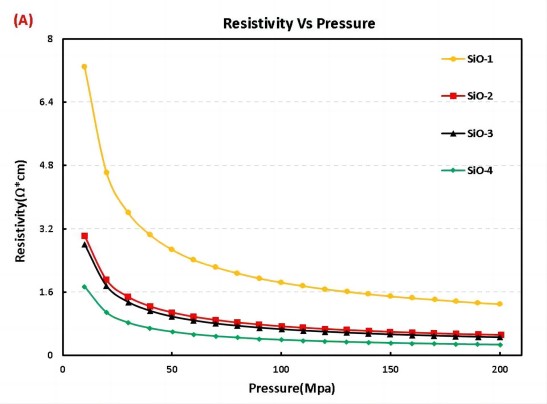

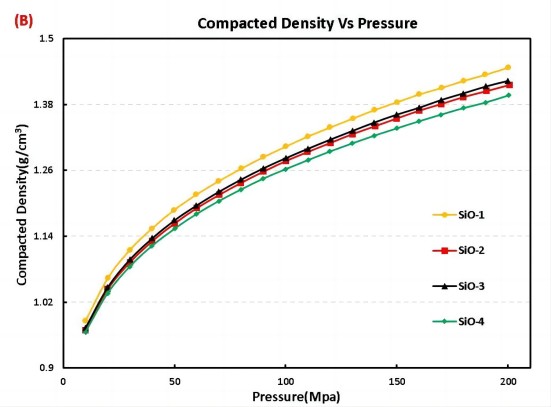

Figure 8 shows the measurement results of the resistivity and compaction density of the four siliceous oxide-based materials as a function of pressure. It can be seen from Figure (A) that the resistivity of the four materials is SiO-1 < SiO-2 < SiO- 3<SiO-4, that is, with the increase of sintering temperature, the electrical conductivity of the material is getting better and better, this may be because with the increase of sintering temperature, the overall coating of the material becomes better, thereby making its electrical conductivity get better. Figure (B) shows the change curve of the compacted density of the four materials with the pressure. It can be clearly seen from the figure that the overall difference of the compacted density is not large when the pressure is small, and the difference of the compacted density is gradually reduced with the increase of the pressure. However, the overall difference is less than 0.05g/cm³.

In conclusion, surface-coated carbon materials improve the electrochemical performance due to the following reasons: (1) the carbon layer provides an elastic shell and reduces the volume change during alloying/dealloying; (2) reduces the interaction between the active material and the electrolyte side reactions; (3) the carbon layer provides a large number of lithium ion and electron transport channels, thereby improving the applicability of silicon-oxygen materials.

Figure 8. (A) and (B) are the resistivity and compaction density of the four siliceous oxide-based materials as a function of pressure, respectively.

3.Conclusion

This paper uses PRCD3100 to test the electrical conductivity, compaction density and compressive properties of silicon-based materials, evaluates the difference analysis of materials under different mixing ratios and different modification process conditions, and provides a new idea for material modification and difference analysis and evaluation. direction.

4.References

1. Wu H, Cui, Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today, 7, 414-429, (2012).

2. Guerfi A, Hovington P, Charest P, et al. Nanostructured Carbon Coated Si and SiOx Anodes for High Energy Lithium-ion Batteries. 2011.

3. Lin Ning. Preparation and electrochemical performance of silicon-based anode materials for lithium-ion batteries [D]. University of Science and Technology of China, 2016.