Conductivity and Compaction Density Test of Na-ion Positive and Negative Materials

Sodium and lithium belong to the same family of elements, and their chemical properties are similar. However, compared with lithium, sodium has obvious advantages in terms of resource reserves and cost. At the same time, sodium-ion batteries can be quickly charged and discharged. The process is the same as that of lithium batteries, which makes it a potential substitute for lithium-ion batteries and is expected to become the next generation of commercial energy storage devices. With the gradual advancement of sodium-ion battery research, breakthroughs have been made in positive and negative energy storage materials for sodium-ion batteries. The positive electrode materials for sodium-ion batteries mainly include oxides, polyanions, Prussian blue, and organics. ; Negative electrode materials mainly include carbon-based, titanium-based, organic, alloy and other negative electrode materials.

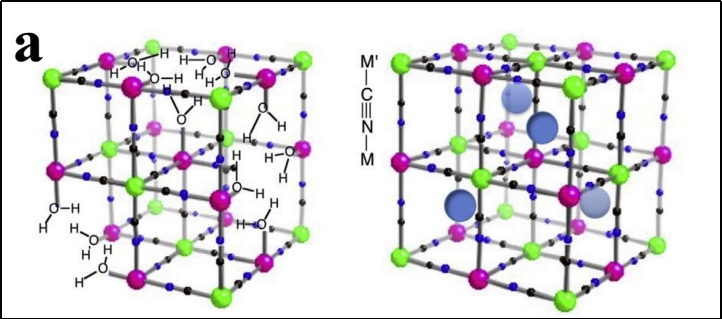

Prussian blue (PB) as a representative material of metal-organic frameworks (MOFs) in the research of sodium ion cathode materials has attracted attention due to its low cost, facile preparation process and hollow framework structure. Studies have shown that PB-derived nanomaterials can inherit some of their characteristics, exhibiting large surface areas, interconnected pores, and graded pore sizes, which can facilitate charge transfer when used in energy storage and conversion systems. By adjusting the synthesis conditions (such as temperature and atmosphere), nanomaterials with ideal structure and properties can be obtained, which can be widely used in the field of energy storage [1]. Figure 1 is a schematic diagram of the crystal structure of Prussian blue and its derivatives. 2 is the SEM image of Prussian blue and its derivatives.

Figure 1.Schematic diagram of the crystal structure of Prussian blue and its derivatives[1]

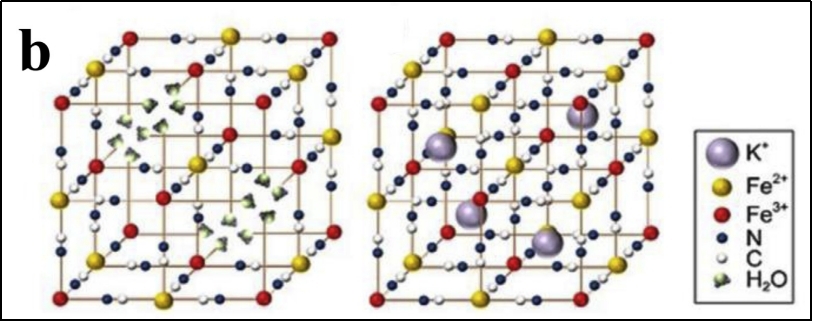

Figure 2.SEM image of Prussian blue and its derivatives: (a)Na0.67Ni0.33Mn0.67O2 (b)Na0.67Ni0.33Mn0.66Sn0.01O2 (c) Na0.67Ni0.33Mn0.64Sn0.03O2 和 (d)Na0.67Ni0.33Mn0.62Sn0.05O2[2]

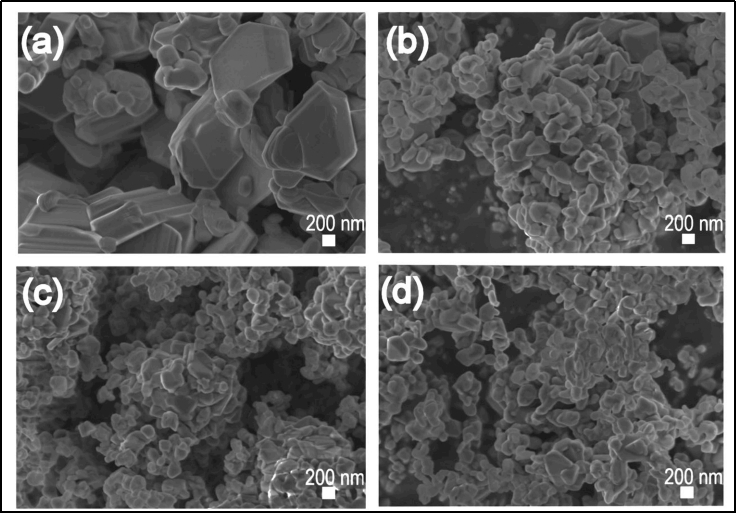

Among the anode materials, carbon-based anodes not only have a low sodium intercalation platform, high capacity and good cycle stability, but also have the advantages of abundant resources and simple preparation, and are currently the most promising sodium storage anode materials. Among them, hard carbon materials have become ideal materials for commercialization due to their advantages such as large interlayer spacing, low cost, simple synthesis method, and the possibility of using renewable resources as precursors. Figure 3 is a schematic diagram of the synthesis of hard carbon and a characterization diagram of the microscopic morphology and structure.

Figure 3. Schematic diagram of hard carbon synthesis and microstructure characterization diagram[3]

In this paper, four Prussian blue (PB) and hard carbon (HC) materials were selected, and the differences between the materials were evaluated by testing the electrical conductivity and compaction density under different pressure conditions.

1.Test Method

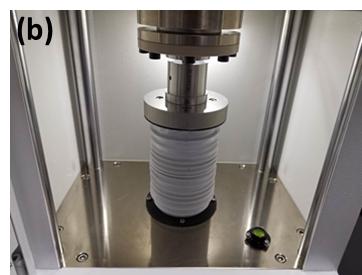

1.1 The PRCD3100 (IEST) is used for four kinds of Prussian blue (PB-1/PB-2/PB-3/PB-4) materials and four kinds of hard carbon (HC-1/HC-2/ HC-3/HC-4) materials were tested for electrical conductivity and compaction density. Among them, Prussian blue materials were tested in two-probe mode, and hard carbon materials were tested in four-probe mode. The test equipment is shown in Figure 2.

Test Parameters: the applied pressure range is 10-200MPa, the interval is 20MPa, and the pressure is maintained for 10s.

Figure 4. (a) Appearance of PRCD3100

(b) Structure diagram of PRCD3100

2.Test Results and Analysis

Prussian blue (PB) and its analogs have channels composed of three-dimensional framework structures, which can facilitate the insertion and extraction of sodium ions, and are ideal cathode materials for sodium ion batteries. The material can provide a theoretical specific capacity of 170 mAh/g with good cycling stability. However, its low cycling stability and rate capability in electrochemical tests often limit its practical application in Na-ion batteries. The main reason for affecting its electrochemical performance is that a large number of vacancies and coordination water appear in the crystal structure of the material, occupying many electrochemical reaction sites, reducing the specific capacity of the material.

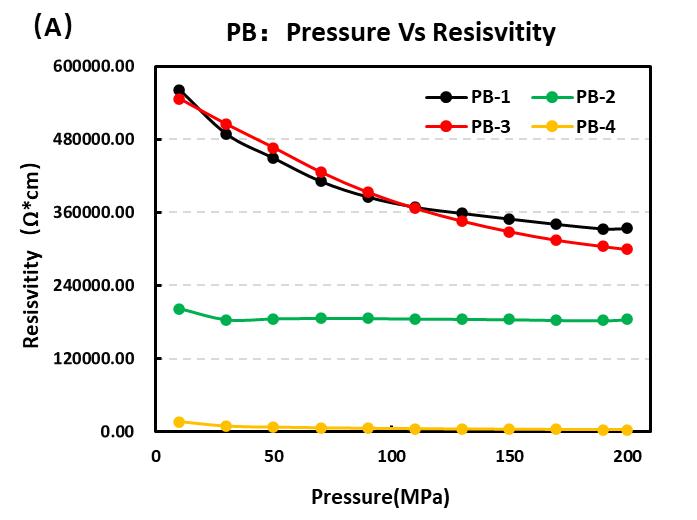

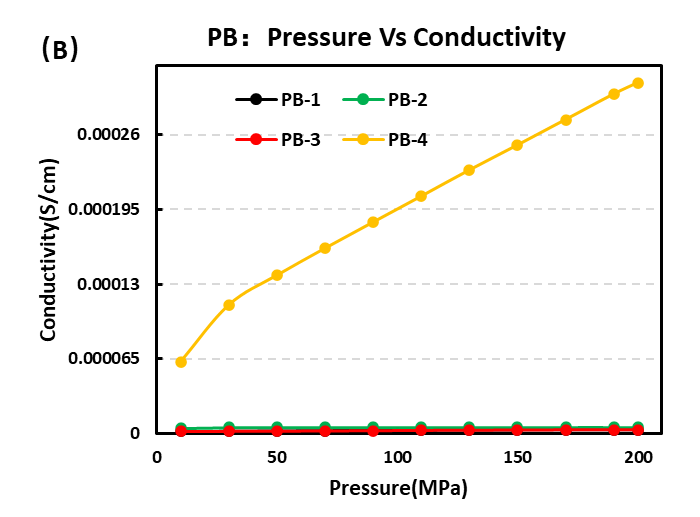

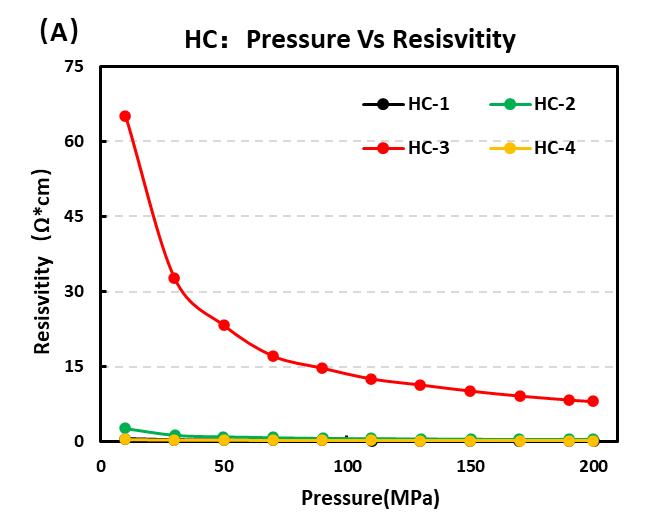

At the same time, the existence of vacancies will also cause the structure to collapse due to the migration of sodium ions, and the coordinated water in the structure reduces the electrical conductivity of the material. In practical applications, researchers optimize its physical and electrochemical properties by modifying it. , and the evaluation of the electronic conductivity at the material end can be used as an effective evaluation method. Figure 5 shows the test results of resistivity and electrical conductivity of four Prussian blue materials, of which PB-2 is modified on the basis of PB-1, and PB-4 is modified on the basis of PB-3. From the rate test results, it can be seen that PB-1, PB-3>PB-2>PB-4, the two modified materials have better conductivity.

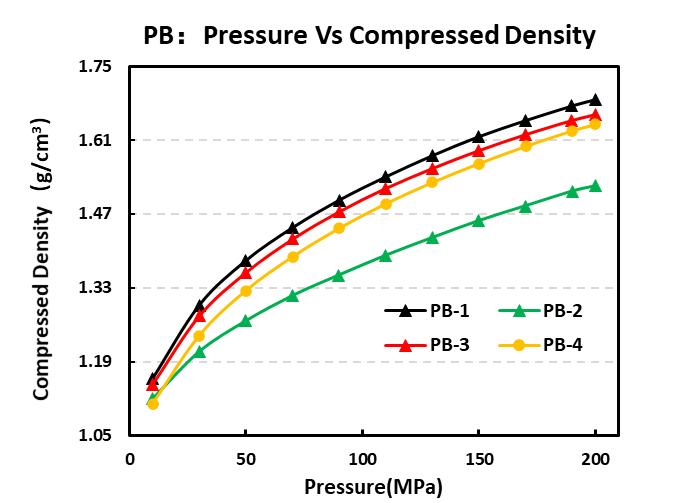

In the production process of lithium-ion power batteries, the compaction density has a great influence on the performance of the battery. Compaction density is closely related to specific capacity, efficiency, internal resistance, and battery cycle performance. Figure 6 shows the compaction density test results of the four Prussian materials, PB-1>PB-3>PB-4>PB-2, the compaction density of the two modified materials under the current test conditions did not show Better, it can be seen that in the actual research and development work, it is necessary to comprehensively evaluate the overall performance of the material by combining various means, so as to finally obtain a material with better overall performance.

Figure 5. (A) The resistivity test results of four Prussian blue-like materials;

(B) Conductivity test results of four Prussian blue-like materials

Figure 6. Compaction density test results for four Prussian blue-like materials

Hard carbon materials are considered to be the most promising anode materials for the development of sodium-ion batteries. Researchers have improved the rate capability by controlling the morphology of hard carbon materials, introducing pore structures or constructing three-dimensional inline structures in hard carbon materials. By controlling the different carbonization processes, the microstructure of hard carbon materials, especially the graphite-like microcrystalline structure, can be adjusted to improve the thermodynamic process of sodium ion insertion and increase the sodium storage capacity of the material [4].

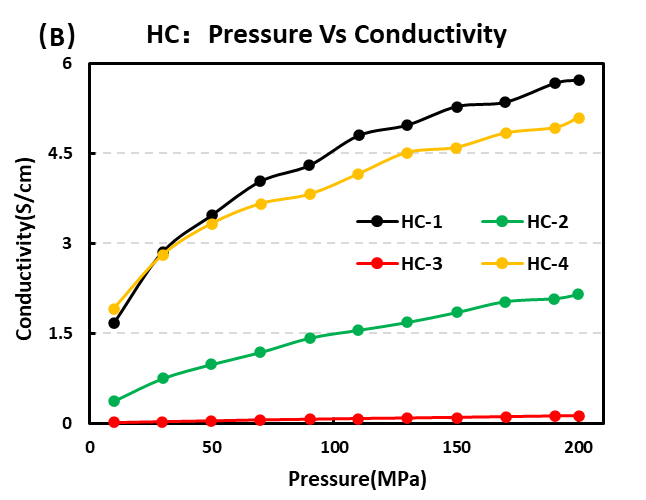

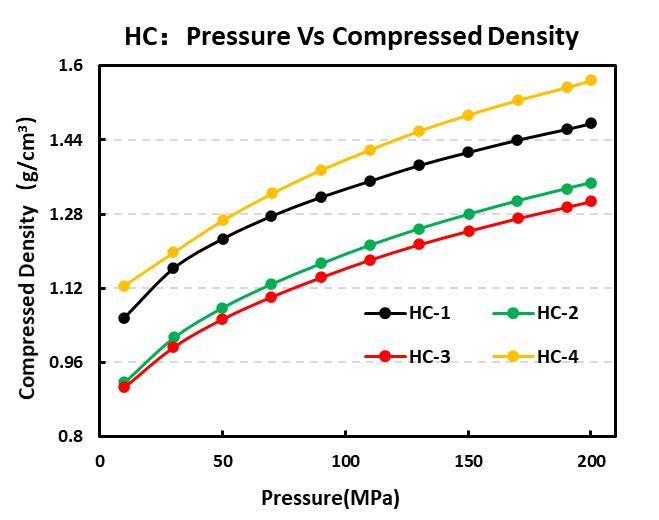

The resistivity and conductivity test results of the four hard carbon materials selected in this paper are shown in Figure 7 A and B. From the conductivity test results, HC-1>HC-4>HC-2>HC-3, namely HC -1 shows better electrical conductivity; the compacted density test results of the four materials are shown in Figure 8. From the compacted density test results, HC-4>HC-1>HC-2>HC-3, four There are obvious distinctions between different materials; the differences in electrical conductivity and compaction density between materials are related to their process, crystal morphology, internal structure and surface state.

Figure 7. (A) The resistivity test results of four hard carbon materials;

(B) Conductivity test results of four hard carbon materials

Figure 8. Compaction density test results of four hard carbon materials

3.Summary

In this paper, the powder resistance & compaction density (PRCD3100) equipment was used to detect the difference in electrical conductivity and compaction density between the positive electrode material Prussian blue and the negative electrode material hard carbon for sodium ion batteries. The test results show that the difference between different materials can be clearly distinguished. As an effective method for testing the physical properties of materials, it helps developers to quickly evaluate the differences in electrical conductivity and compaction density at the material level.

4.References

[1] Chen J, Wei L, Mahmood A, et al. Prussian blue, its analogues and their derived materials for electrochemical energy storage and conversion - ScienceDirect[J]. Energy Storage Materials, 2020, 25:585-612.

[2] Li J,Risthaus T , Wang J , et al. The effect of Sn substitution on the structure and oxygen activity of Na0.67Ni0.33Mn0.67O2 cathode materials for sodium ion batteries[J]. Journal of Power Sources, 2019, 449:227554.

[3] Yin X, Lu Z, Wang J, et al. Enabling Fast Na+ Transfer Kinetics in the Whole-Voltage-Region of Hard-Carbon Anodes for Ultrahigh-Rate Sodium Storage[J]. Advanced Materials, 2022.

[4] Wu Junda, Zhao Yabin, Zhang Fuming. Research progress of hard carbon materials as anode materials for room temperature sodium-ion batteries [J]. Shandong Chemical Industry, 2019, 48(9):3.