The 'Tough Guy' of Lithium Battery Particles and the 'Tale of Transformation' of Powders

The 'Tough Guy' of Lithium Battery Particles and the 'Tale of Transformation' of Powders

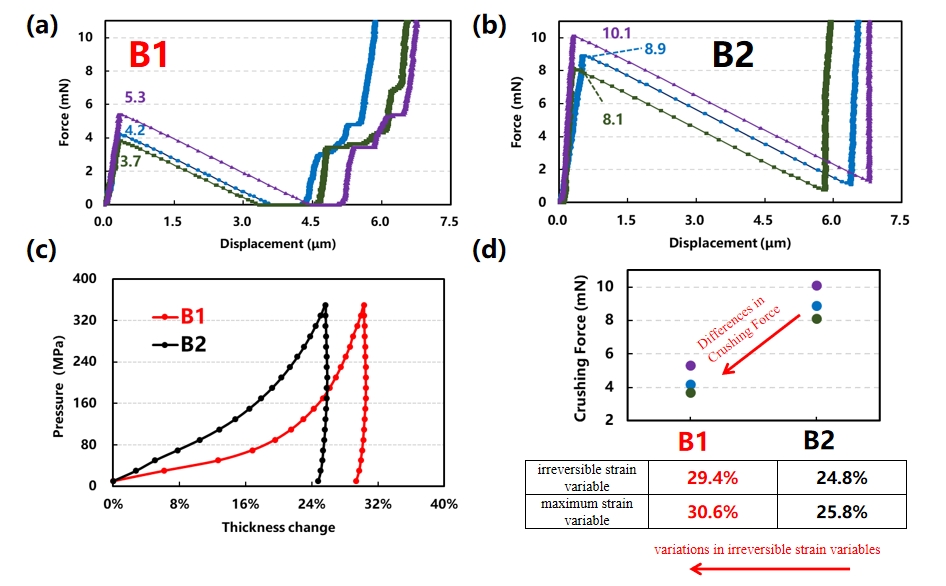

1.Background

During the production process of lithium-ion battery electrodes, especially in the rolling process, a certain degree of particle breakage is difficult to completely avoid. When the slurry formed by mixing active material powder with conductive agents, binders, etc., is coated on the current collector and dried, and then the electrode density is increased through the rolling process, significant mechanical pressure may cause varying degrees of particle breakage or rupture between active material particles and within the particles themselves, leading to irreversible deformation and deterioration of material properties.

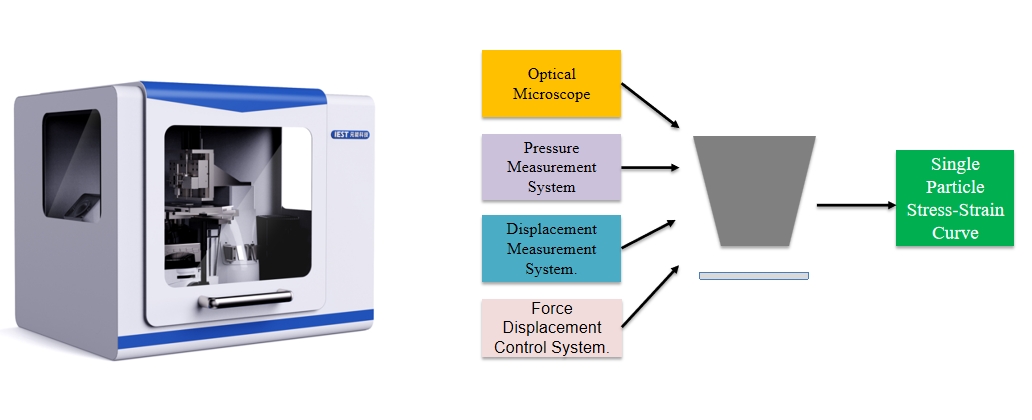

Figure 1. Influence of Particle Compressive Strength on Powder Compression and Electrochemical Performance of Electrodes

The compressive strength of individual particles in lithium battery materials is closely linked to the irreversible deformation that occurs in the powder during compression (Figure 1). Compressive strength reflects the ability of particles to resist damage when subjected to external forces, while the irreversible deformation of the powder refers to the plastic deformation or breakage of powder particles during compression, resulting in shape changes that cannot be fully restored to their original state.

Firstly, materials with high compressive strength of individual particles are less prone to breakage or plastic deformation during the compression process. This means that under the same compression conditions, particles with high compressive strength can better maintain particle integrity, reduce the occurrence of irreversible deformation, thereby contributing to the stability and consistency of electrode structure, and improving the performance of the battery. Secondly, the occurrence of irreversible deformation is closely related to the interaction and contact status between particles. During the compression process of powder, the contact area and interaction force between particles may change, leading to plastic deformation or breakage of particles. Particles with high compressive strength can better resist such interaction forces, reducing the occurrence of irreversible deformation.

Additionally, irreversible deformation of the material may also affect the electrode's pore structure and ion transport properties. If significant irreversible deformation occurs in the material, it may lead to collapse of the electrode's pore structure, reducing ion transport efficiency, thereby affecting the electrochemical performance of the battery cell.

In summary, the compressive strength of individual particles has a significant impact on the occurrence of irreversible deformation in powder. Enhancing the compressive strength of particles can reduce irreversible deformation, maintain the stability and consistency of electrode structure, thereby improving the performance of the battery cell. Therefore, in the design and preparation process of lithium battery materials, it is necessary to fully consider the causal relationship between the compressive strength of individual particles and the irreversible deformation of powder.

2.Testing Methods

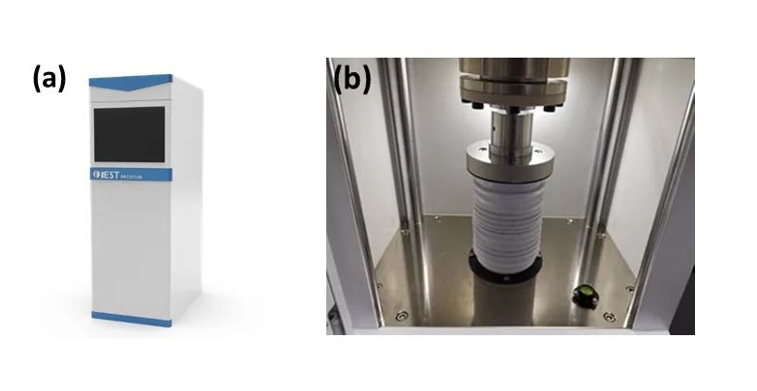

In this study, different types of positive ternary electrode materials, negative pure carbon materials, and negative silicon-carbon materials were selected for characterization using two testing devices: the IEST single particle mechanical property testing system and a powder compaction density analyzer. These tests aimed to reveal the relationship between the compressive strength of lithium battery materials at the single particle level and the irreversible deformation occurring during powder compression.

The compressive strength of individual particles of positive and negative electrode materials was tested using the Single Particle Force Testing System (SPFT2000, IEST). The compression performance of powder materials was evaluated using the Powder Resistance & Compaction Density Analyzer PRCD3100 (IEST) series equipment. The testing parameters were as follows: pressure range of 10 to 200 (or 400) MPa, with intervals of 10 (or 20) MPa, and a hold time of 10 seconds. The testing equipment is shown in Figures 2 and 3.

Figure 2. Appearance and Functional Modules of the Single Particle Force Testing System SPFT

Figure 3. Schematic Diagram of the Appearance and Structure of the PRCD Series

3. Testing Cases

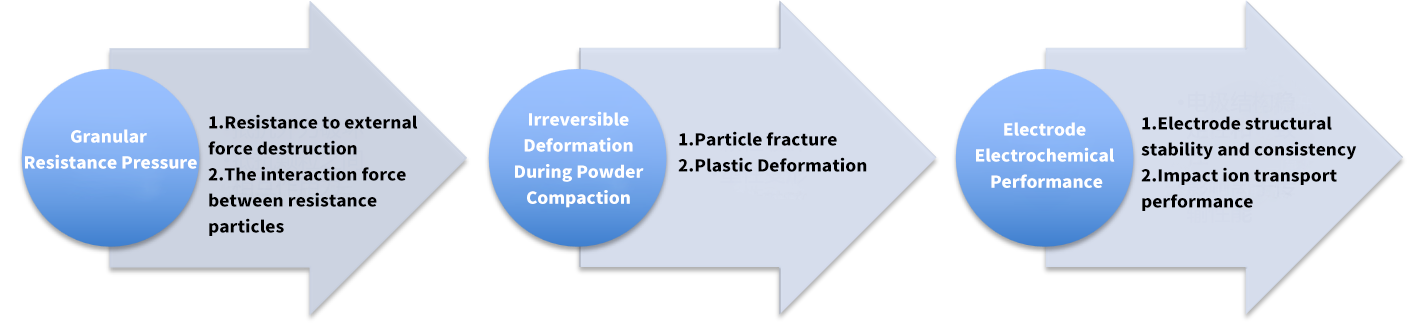

1.Ternary Materials B1 and B2

The two ternary materials, B1 and B2, are sintered from different precursors, with a particle size D50 of 9.5μm. The results of the single particle mechanical properties for both materials are shown in Figures 4(a) and 4(b). The average crush force of B1 is 4.4mN, while that of B2 is 9mN, indicating a higher crush force for B2 compared to B1. Upon crush, the stress drops to zero for B1, whereas for B2, the force drops to 2mN. Additionally, after crush, B1 exhibits multiple plateaus on the force-displacement curve as the platen continues to compress, suggesting a faster structural breakdown and lower elasticity compared to B2. Moreover, during the platen compression process, some particles of B1 may undergo secondary crushing after initial fracture.

By gradually increasing the pressure step by step until reaching the maximum pressure and then gradually releasing the pressure to the minimum, stress-strain curves for the powders of the two materials are obtained, as shown in Figures 4(c) and 4(d). From the slope of the stress-strain curve, it can be observed that the compression modulus of B2 is greater than that of B1, indicating that it is more resistant to compression. Numerically, both the maximum strain variable and irreversible strain variable of B1 are greater than those of B2, consistent with the difference in single particle crush force.

Figure 4. (a) Single particle crush curves for B1 and (b) B2 particles; (c) Stress-strain curves for powders of B1 and B2; (d) Comparison of the numerical distribution of single particle crush for B1 and B2 and irreversible deformation during powder compression.

2. Graphite Materials C1 and C2

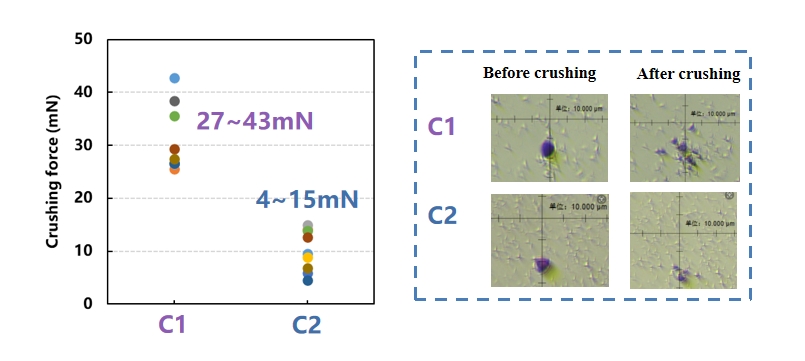

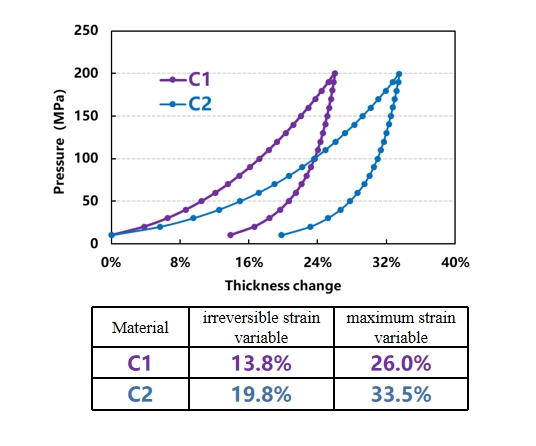

There are differences in the production processes of the two pure carbon materials, C1 and C2, with particle sizes generally ranging from 6 to 8 μm. Figure 5 shows the distribution of single particle crush forces for the two materials. It can be observed that even for the same pure carbon material, there are differences in the crush forces of different particles: C1 ranges from 27 to 43 mN, while C2 ranges from 4 to 15 mN. However, there are significant overall differences in the distribution of crush forces between the two samples. The results of powder compression performance testing (Figure 6) show that the compression modulus of C1 is greater than that of C2, and both the maximum strain variable and irreversible strain variable are smaller than those of C2. This indicates that if the compressive strength of the particles in the material is weak, significant deformation is likely to occur during powder compression, including irreversible deformation. This deformation can lead to changes in the internal structure of the material, thereby affecting its overall mechanical properties and durability.

Figure 5. Distribution of single particle crush forces and schematic diagram of single particle crush before and after for particles of C1 and C2.

Figure 6. Stress-strain curves and strain variable numerical values for powders of C1 and C2.

3. Silicon-carbon Materials SC-1, SC-2, and SC-3

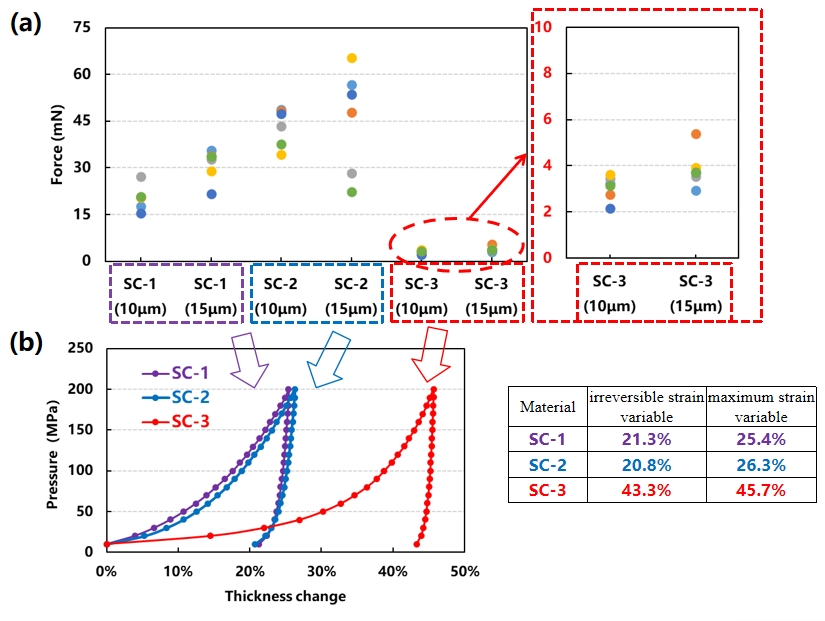

Figure 7. Distribution of single particle crush forces for different particles of SC-1, SC-2, and SC-3 (a), and stress-strain curves and strain variable numerical values for powder compression (b).

The three carbon-silicon materials, SC-1, CSC-2, and SC-3, have different silicon contents and slight structural differences. Additionally, the microscopic particle sizes of the three materials are not completely uniform. Observations under the optical microscope of the Single Particle Force Testing System show that the majority of particles for each material have diameters around 10μm and 15μm, with a relatively large proportion of particles at 15μm. We selected different particles of 10μm and 15μm from each material for single particle mechanical property testing, and the distribution of single particle crush forces is shown in Figure 7(a). Overall, the crush force of SC-2 is slightly greater than that of SC-1, and both are significantly greater than that of SC-3. The crush force distribution of SC-1 is more concentrated, indicating better particle uniformity, while in SC-2, there is a larger variation in crush force for the 15μm particles, ranging from 22.2 to 65.4mN. The results of powder compression performance testing for the three materials are shown in Figure 7(b). Due to its weaker particle compressive strength, SC-3 exhibits significantly larger maximum strain and irreversible strain during powder compression compared to the other two materials. Although the compressive strength of SC-2 particles is slightly higher overall than that of SC-1, differences in particle compressive consistency during powder compression may lead to effects such as the fracture of stronger particles due to weaker ones or stress concentration, or uneven compression affecting the recovery ability, resulting in similar compression performance and strain variables between SC-1 and SC-2 overall.

4. Conclusion

This article focuses on the testing method of lithium battery single particle mechanical properties, combined with the testing of powder compression performance, to effectively evaluate the compressive resistance of different material particles in lithium batteries at various levels. It reveals the close causal relationship between single particle compressive strength and the irreversible deformation occurring during powder compression. This causal relationship indicates that by improving the compressive strength of individual particles, the risk of fracture, breakage, and irreversible deformation of particles during rolling or battery cycling processes can be effectively reduced, thereby enhancing the overall performance of the battery.