Research on the Application of Powder Resistivity & Compaction Density in Quality Control

The electrochemical performance of lithium-ion batteries is closely related to the performance of positive and negative electrode powder materials. Among them, the existence of problems such as the content of metal foreign matter impurities in positive electrode materials, excessive moisture, and poor batch consistency may cause lithium-ion batteries to fail or even cause safety problems. For battery companies, incoming inspection is a key link in the battery manufacturing process. In incoming inspection, the smaller the difference between batches of positive electrode powder materials, the better the consistency and the more stable the finished battery. In the batch stability control of positive electrode materials, particle size, tap density, compacted density, specific surface area, moisture, pH value, resistivity, etc. are strictly monitored as standard monitoring indicators. In this paper, IEST PRCD 3100 is used to test the long-term stability of powder resistivity and compacted density and provides a monitoring method for the performance consistency of powder materials.

1. Indicators and Monitoring Methods

1.1 Different batches of the same NCM material are separately packaged, and one package is unpacked every day for 3 sets of repetitive tests, with a total of 30 days of testing.

1.2 Use PRCD3100 (IEST) to test the resistivity and compaction density of the material respectively. The test equipment is shown in Figure 2.

Test Parameters: pressure range 12-20MPa, interval 2MPa, hold pressure 10s; 80-180MPa, interval 50MPa, hold pressure 10s.

Figure 2. (a) Appearance of PRCD3100; (b) Structure of PRCD3100

2.Test Results

2.1 Precautions Before Testing

There are many factors affecting the resistivity and compacted density stability test, including human, machine, material, method, environment, etc., the proficiency of personnel operating methods, control of key details, stability of test equipment, and samples to be tested. The state, the rationality of the test principle selection, and the stability of the test environment are all key factors in the stability test of resistivity and compacted density. In order to ensure the reliability of the overall test data, the key modules of the equipment need to be systematically tested and calibrated before the experimental test, which mainly includes the calibration of the pressure module, thickness module and resistance module to ensure the accuracy of the overall test of the equipment.

The actual test is carried out under the temperature-controlled environment of 25°C±2°C; the sample selection ensures that the sample state is consistent, and there is no abnormal agglomeration or agglomeration. Different batches are packaged separately, with a total of 30 packages, to minimize the change of samples over time Affected by the environment, if moisture absorption occurs, the actual test process unpacks one package per day and repeats 3 sets of repetitive tests. Since PRCD3100 is a dual-function device for resistivity and compaction density, the two parameters are output from the same set of parameters. After the test is completed, systematically summarize and analyze the 30-day data, including the summary mean, coefficient of variation, range, standard deviation (sigma) and control limits of plus or minus three sigma of the test results under different pressure points.

2.2 Resistivity Test Results

Resistivity is a physical quantity that characterizes the resistance characteristics of materials. The determination of resistivity of lithium-ion battery powder can be used for material modification evaluation, process condition evaluation and quality monitoring. With the development of lithium-ion battery industry, the variety of materials is more diversified , the production process is more complicated, and the risk of material failure is greater, so the requirements for its quality management are also higher. This experiment is based on the long-term stability monitoring of the resistivity of powder materials, and explores the use of powder resistivity detection in Applications in quality control.

Table 1. Summary Table of 30-day Resistivity Test Data Analysis

As shown in Table 1, the analysis summary table of the 30-day resistivity test data of NCM samples is shown. From the test data, it can be seen that the resistivity of the powder sample decreases with the increase of pressure, and the analysis results of its coefficient of variation COV show that the low-pressure The COV of the 30-day test data is 4.13% at a strong pressure of 12MPa, and 2.28% at a high pressure of 180MPa. The overall test repeatability is at a good level, but strictly compared, the repeatability COV at a low pressure is too large, mainly because In the actual resistivity measurement process, the powder filling is not tight under low pressure conditions, the void ratio between powder particles is large, and the repeatability test consistency is relatively poor.

As the pressure increases, the powder particles slide and rearrange to form In a tight stacking state, the void ratio between particles is reduced, and the repeatability test consistency becomes better. At the same time, a large pressure can reduce a part of the contact resistance during the test process, thereby improving the repeatability and consistency of the overall test. This is also the actual test One of the reasons why it is recommended to use high pressure conditions for testing.

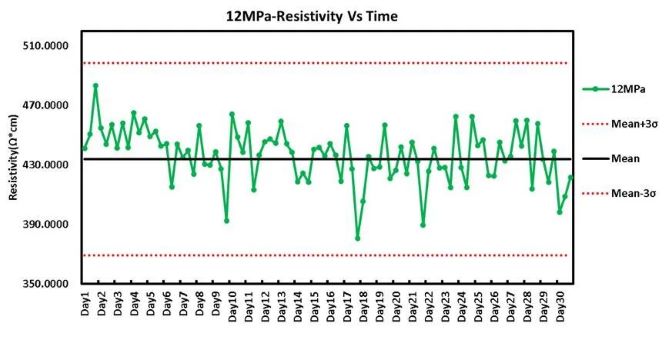

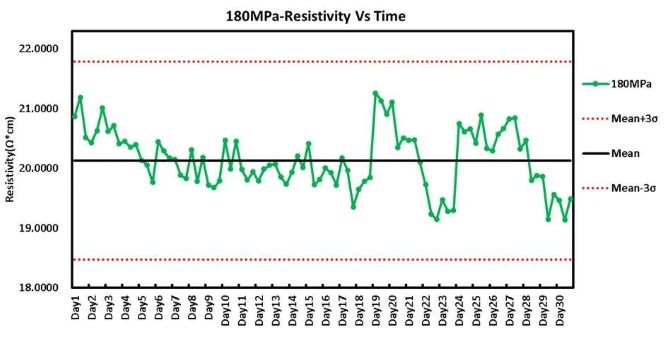

Figure 3. Summary of overall fluctuations of 30-day resistivity test data under 12MPa and 180Mpa pressures

Sigma is a measurement unit of standard deviation, represented by the Greek letter (σ). In the quality monitoring of lithium-ion battery incoming materials, Sigma is a key indicator. Usually, the standard specification is 2~3σ of the average value of long-term data monitoring. Figure 3 is a summary chart of the overall fluctuation of the 30-day resistivity test data under the pressure of 12MPa and 180Mpa. Combining the analysis data in Table 1, it can be clearly seen that the 30-day data of the material all meet the range of Mean±3σ. In actual quality monitoring, resistivity can be used as a key indicator. Combined with the real situation of resistivity tests of different batches of samples in the early stage, systematically analyze the fluctuations of the coefficient of variation, mean value and sigma, etc., and determine 2~3σ as the standard Standardized monitoring specifications can be combined with the specifications and actual application scenarios in the later stage, such as batch stability process evaluation, incoming material consistency monitoring, etc.

2.3 Compaction Density Test Results

With the development of lithium-ion batteries, in order to pursue the development of higher-performance lithium-ion batteries, more and more companies have started the research and development and production of high-capacity, high-voltage and high-density materials to meet the needs of more consumers. The evaluation of compaction density in the industry mostly stays at the electrode end. Experiments have proved that compaction density is closely related to specific capacity, efficiency, internal resistance and battery cycle performance.

To a certain extent, the greater the compaction density, the higher the specific capacity of the battery. Therefore, the effective evaluation of the compaction density is very important for the optimization and improvement of the battery. Compared with the evaluation of the compaction density at the electrode end, the rapid evaluation of the density from the powder material end can also be used as an effective means of material evaluation and screening. At the same time, in quality monitoring aspect is also very important.

Table 2. Summary Table of 30-day Compaction Density Test Data Analysis

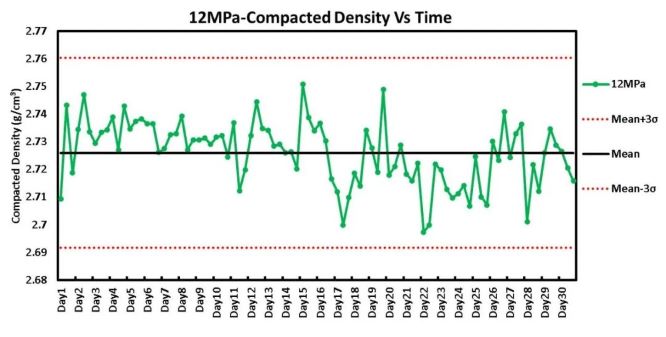

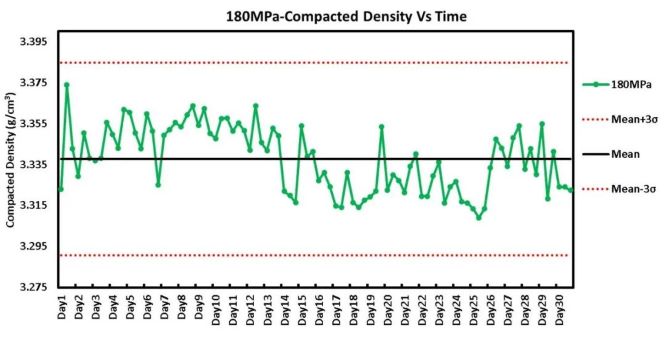

For example, Table 2 is the overall summary table of the 30-day compaction density data of NCM samples. From the data point of view, the compaction density increases with the increase of pressure, and the repeatability COV of the overall data is less than 0.5%, and the repeatability test is extremely high. The difference is less than 0.06g/cm³, and the overall test stability and repeatability of the data are good. Further systematically analyzed the ±3σ range of the compacted density, and combined with the 30-day data to carry out a systematic summary of the compacted density fluctuations. It satisfies the specification range of ±3σ, but compared with the data fluctuation at 12MPa, the data fluctuation at 180MPa is smaller, which has a certain relationship with the state of powder voids under different pressures and the rearrangement of particles with pressure flow.

In addition, The overall fluctuation of the compaction density is also closely related to the control of key points of the test, such as sample state, equipment stability, test mold stability and other factors. In the actual test process, it is also necessary to reasonably control these key factors to minimize the influence factors are minimized. In the actual quality monitoring, similar to the application of resistivity, a large number of parameters related to compaction density can be collected for different sample test requirements and test scenarios in the early stage of research and development, and key factors can be controlled to systematically analyze the sigma of material compaction density The specification range or the strict extreme monitoring range can be used to measure the compaction density of new batches of samples or incoming materials, so as to achieve the purpose of quality monitoring.

Figure 4. Summary of the overall fluctuation of the 30-day compacted density test data under 12MPa and 180Mpa pressures

3.Summary

This paper uses PRCD3100 to test the resistivity and compaction density of the same material for 30 days. Through systematic analysis of the data, it shows the application scenario in the direction of quality monitoring, providing a method for sample batch stability monitoring, and for lithium battery materials. Stable production and new process optimization support.

4.References

[1] Liang Huamei, Zeng Yong, Huang Shijian, et al. Research on the conditions of compaction density test for lithium battery cathode materials [J]. Guangdong Chemical Industry, 2021, 48(19):3.

[2] Zhu Jie, He Jingyuan, Wang Jing. Factors Affecting the Measurement Results of Powder Resistivity[J]. Carbon Technology, 2002(3):3.

[3] Li Xia. Analysis of Influencing Factors of Measuring Results of Resistivity of Blue Coke Powder [J]. China Salt Industry, 2020(9): 4.

[4] Jia Hongying. Quality management of lithium-ion battery cathode materials [J]. Science and Technology Innovation Herald, 2017, 14(17): 2.