A New Lithium Battery Material Testing Solution

The positive and negative electrode materials of lithium-ion batteries, such as lithium iron phosphate, ternary materials, graphite, silicon carbon negative electrode, etc., are widely used commercial materials. With the rapid development of the new energy industry, battery cell manufacturers have higher requirements for battery material capacity, cycle performance, safety and other aspects.

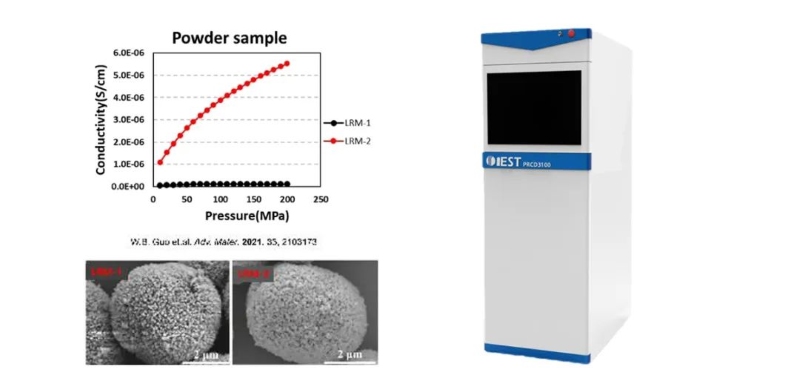

Many researchers at home and abroad are committed to modifying commercial materials, such as nanomaterials, surface coating, ion doping, structural design, etc., or developing the next generation of new materials such as lithium-rich manganese-based materials, silicon-oxygen negative electrode materials. Lithium-rich manganese-based materials are popular materials for research in colleges and universities. Generally, the performance of materials is improved by means of grain-controlled growth, bulk phase doping, and optimized preparation processes. To characterize the modified material, the method of testing material compaction and resistivity can be used to preliminarily evaluate the performance of the material, so that the modification effect can be quickly judged.

IEST has developed PRCD and PCD series products for material compaction and electrical resistivity testing. Real-time testing of powder conductivity and compaction density of positive and negative electrode materials by PRCD series equipment can evaluate the effect of material modification and batch stability of materials.

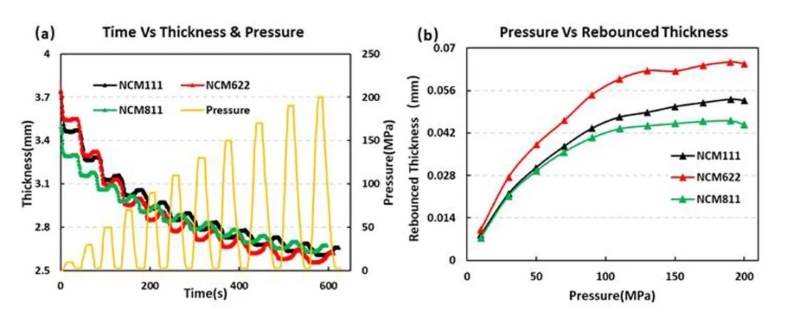

With the development of the lithium-ion battery industry and the emphasis on the compaction density index of materials, the compressibility of powder materials has gradually attracted the attention of researchers. Powder has fluidity like liquid, compressibility like gas, and has the ability to resist deformation of solid. It will be affected by the powder particle size and its distribution, shape, density, specific surface area, void distribution, surface properties, mechanical properties and flow properties during the compression process, and finally show different filling properties and compression properties.

Using the pressure relief mode of PRCD series equipment, the thickness rebound curve or stress-strain curve of the powder material can be obtained, and the elastic deformation and plastic deformation of the material can be calculated, so as to characterize the compression properties of the positive and negative electrode materials and evaluate the material strength.