Research Status and Conductivity Performance Evaluation of Lithium Iron Manganese Phosphate Materials

1. Research Background

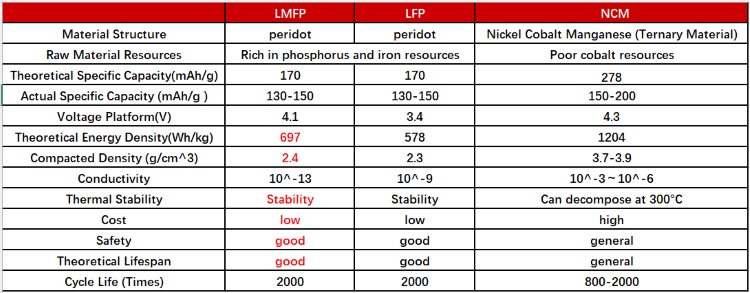

At present, the cathode materials of lithium-ion batteries are mainly lithium cobalt oxide (LCO), ternary material (NCM) and lithium iron phosphate (LFP). In the past one or two years, with the increase of electric vehicles and the gradual release of energy storage, everyone's attention to battery safety is also gradually increasing, in addition to the improvement of battery design technology (such as BYD's blade battery, CATL's CTP technology, etc.), the research and development of new materials is also particularly critical. Due to its high safety, LFP has gradually become the main cathode material for electric vehicles or energy storage batteries. However, for LFP batteries, the development of its energy density has almost reached its limit, and there is little room for performance improvement. The crystal structure of lithium manganese iron phosphate (LMFP) is similar to that of LFP, and it also has the characteristics of stable chemical properties and excellent safety performance, at the same time, the manganese element doped in LMFP can increase the charging voltage of the material, increasing the charging voltage from 3.4V of LFP to 4.1V, which increases the theoretical energy density of the LMFP battery by 15-20%, and further expands the cruising range. The safety performance of LMFP is better than that of NCM, and the energy density is higher than that of LFP. In addition, LMFP is less dependent on rare metals, and can be produced in line with LFP, with obvious cost advantages. The detailed performance comparison between lithium manganese iron phosphate and other cathode materials is shown in Table 1.

Table 1. Comparison Between LMFP and Other Cathode Materials

2.Process Routes

The synthesis methods of LMFP and LFP are basically the same, and the industrial methods are mainly high-temperature solid-phase method, hydrothermal synthesis method, co-precipitation method and so on. At present, there is no unified standard for the preparation process route of LMFP, the technical route of leading manufacturers in the industry is as follows:

(1) Dynanonic: LMFP is mainly prepared by sol-gel method, and the lithium source, manganese source, phosphorus source and iron source are mixed and dissolved in proportion to obtain a liquid slurry, which is dehydrated and crushed, obtain a powdery precursor, then sinter and pulverize to obtain LMFP.

(2) Lithitech: Co-precipitation method is mainly used. Firstly, the precursor containing iron and manganese is obtained by coprecipitation method, and then the precursor is uniformly mixed with lithium source and carbon source to obtain LMFP.

(3) CATL: LMFP is mainly prepared by solvothermal, the required raw materials are dissolved in a solvent, and a uniform solution is prepared, which is transferred to a reaction kettle to react to obtain a precursor, and then dried and sintered to obtain LMFP.

(4) SkYLAND: It is mainly synthesized by high-temperature solid-state method. After uniformly mixing the required raw materials, it is then sintered at high temperature to obtain LMFP, which is then compounded with ternary materials for supply.

3.Material Modification

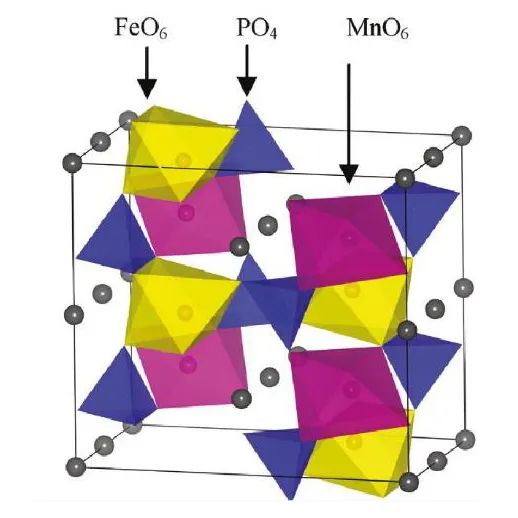

The one-dimensional conduction of lithium ions in the olivine-type cathode material determines its low ion conductivity, in terms of electron transport capability, the conductivity of LMFP is lower than that of LFP with semiconductor properties, the conductivity of LFP is 10-9 S/cm, the conductivity of NCM is 10-3 S/cm, and the conductivity of LMFP is only 10-13 S/cm. From the structural point of view, LMFP does not have a continuous FeO6 (MnO6) shared edge octahedral network, but is connected by PO4 tetrahedrons (as shown in Figure 1), so it cannot form a continuous Co-O-Co structure like lithium cobalt oxide materials. , which restricts the movement of lithium in the one-dimensional channel, resulting in poor conductivity of the material, which in turn leads to poor high-rate charge and discharge performance. The enhancement of electrical conductivity is mainly concentrated on carbon coating and ion doping. Carbon coating mainly improves the electronic conductivity, while ion doping mainly increases the ion diffusion coefficient and conductivity.

Figure 1. Schematic diagram of the structure of olivine-type LMFP[1]

Adding an appropriate amount of carbon in the material synthesis process can not only improve the conductivity of the material, but also prevent the contact between particles, inhibit the agglomeration and growth of particles, therefore, it is easier to obtain nanoscale cathode materials [2, 3], which can effectively reduce the diffusion distance of Li inside the active particles, and make the material have a more excellent rate. At the same time, the carbon coating can also reduce the contact surface between the active material and the electrolyte, to avoid side reactions with the electrolyte and improve its high temperature performance and cycle performance. Carbon coating is generally divided into two types: one is to fully mix the LMFP finished product with the carbon source, and then calcine the coating at high temperature in a reducing atmosphere; the other is to directly add the carbon source to the raw materials, mix them together, dry them, and sinter them at high temperature, and finally form a carbon-coated LMFP/C composite material. For example, scientific researchers such as Oh used ultrasonic dispersion pyrolysis to synthesize LiMnx Fe1-x PO4 powder [4], and then mixed with carbon source ball mill to obtain carbon-coated olivine-type lithium-ion cathode material. When the material is discharged at a rate of 0.5 C and 2 C, the initial discharge specific capacity is 150 mAh/g and 121 mAh/g, respectively, and the improvement of its electrochemical performance is due to the close combination of primary particles and carbon and the uniform coating of carbon.

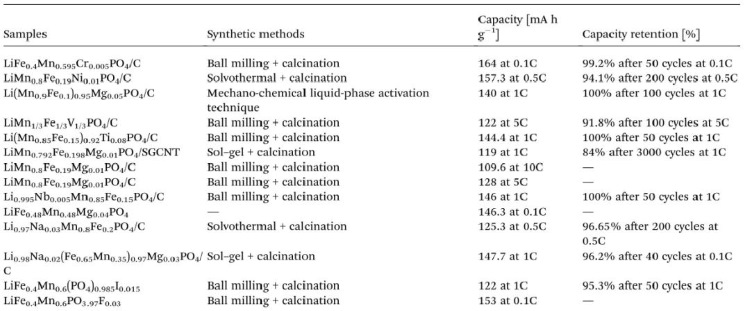

In addition to coating carbon on the surface of the material to improve the electronic conductivity of the material, ion doping is also a common means to improve the diffusion coefficient of lithium and the ion conductivity. Ion doping can form Li site or Fe, Mn site defects in the LMFP lattice, create vacancies in the material lattice or change the bond length between atoms, facilitate the movement of Li+ in the lattice, thereby improving the electrochemical performance of the material [5]. Compared with modification methods such as morphology control and surface coating, the advantage of ion doping is that it has less impact on the tap density of LMFP materials and can increase the volume energy density, which is beneficial to enhance the rate performance of the battery. Table 2 shows a summary of data on element doping modification of LMFP in recent years.

Table 2.Summary of data on the influence of different element doping on the performance of LMFP [6]

4. Conductivity Testing Method

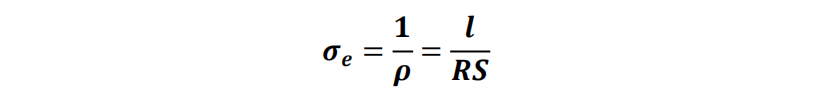

The various methods described above can effectively improve the electrical conductivity and electrochemical performance of the positive electrode material. In terms of performance characterization, researchers usually test their electrochemical performance by assembling button cells or pouch cells, or by testing EIS to characterize the change of its impedance to judge whether the modification effect is good or not, how to accurately and quickly test the change of conductivity before and after material modification? According to Ohm's law R=U/I, the resistance of the conductor can be calculated by testing the current passing through the conductor and the voltage drop passing through the conductor, combined with the geometric size of the sample to be tested, and then the conductivity can be calculated by the following formula.

(σe: Electrical conductivity, ρ: Resistivity, R: Resistance, l: Thickness of material, S: Area of material)

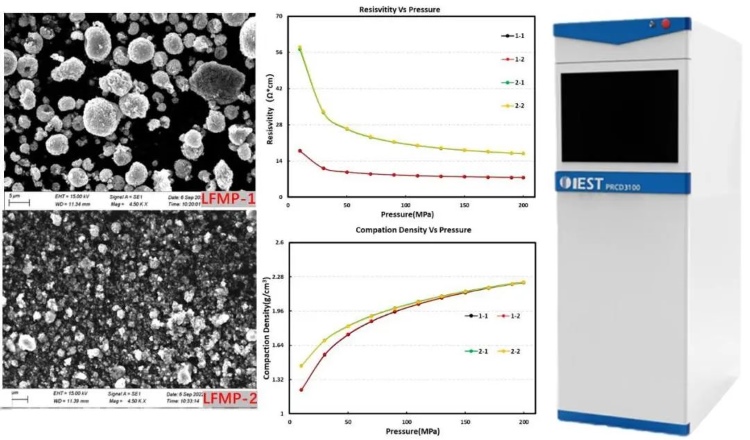

This test method is generally called the direct current method. The electrode material is a mixed conductor of ions and electrons, during the test, through direct current polarization, the high transient current of mixed ions and electrons drops rapidly, and finally reaches a stable electronic current, so that the electronic conductivity is mainly determined. The direct current method also includes the two-probe method and the four-probe method. IEST has found through a large number of test experiments that the two-probe principle is more suitable for samples with slightly higher resistance, such as LCO and low-nickel NCM and other lithium battery cathode materials, the four-probe principle is more suitable for samples with small resistance, such as graphite negative electrodes and various conductive agents, etc.; for samples with resistance values in the ohm level, such as carbon-coated LMFP and LFP, the two principles are equally applicable, and comparative tests have found that, There is little difference in the test results of the two principles overall. For this reason, IEST has independently developed a dual-principle dual-function device suitable for the determination of large and small resistance samples - powder resistance & compaction density meter (PRCD3100, IEST). Figure 2 shows the schematic diagram of the device and the test data of different LFMPs. During the testing process, while applying different pressures (up to 5T) to the powder sample, the equipment can simultaneously collect the resistance, resistivity, conductivity, compaction density and other parameters of the powder sample, and display them on the software interface in real time.

Figure 2. Equipment schematic diagram of powder resistance & compaction density (PRCD3100) and different LFMP test data

5.References

[1] Osorio-Guillén J M,Holm B,Ahuja R,et al.A theoretical study of olivine LiMPO4 cathodes[J]. Solid State Ionics, 2004, 167(3-4): 221-227.

[2] Wang Y, Hu G, Cao Y, et al. Highly atom-economical and environmentally friendly synthesis of LiMn0.8Fe0.2PO4/rGO/C cathode material for lithium-ion batteries[J]. Electrochimica Acta, 2020,354:136743.

[3] Kosova N V, Podgornova O A, Gutakovskii A K. Different electrochemical responses of LiFe0.5Mn0.5PO4 prepared by mechanochemical and solvothermal methods[J]. Journal of Alloys and Compounds, 2018, 742: 454-465.

[4] Oh S M, Jung H G, Yoon C S, et al. Enhanced electrochemical performance of carbon-LiMn1−x FexPO4 nanocomposite cathode for lithium-ion batteries[J]. Journal of Power Sources, 2011, 196(16): 6924-6928.

[5] Budumuru A K, Viji M, Jena A, et al. Mn substitution controlled Li-diffusion in single crystalline nanotubular LiFePO4 high rate-capability cathodes: Experimental and theoretical studies[J]. Journal of Power Sources, 2018, 406: 50-62.

[6] Yang L , Deng W , Xu W ,et al. Olivine LiMnxFe1-xPO4 cathode materials for lithium-ion batteries: restricted factors of rate performances[J].Journal of Materials Chemistry A, 2021, 9: 14214–14232.