Effect of Rolling Pressure on the Compression and Conductivity of Electrode

In the context of a sustainable modern society and climate goals, battery energy storage technology has become an important direction for the transformation of the global automotive industry and the sustainable growth of the global economy. Lithium-ion batteries (LIBs) have become one of the major energy storage solutions in the consumer, power, and energy storage markets due to their long cycle life and high rate performance.At present, there are still challenges in reducing production costs, improving performance and durability of lithium-ion batteries. Therefore, it is of great significance to have a deep understanding of the impact of the production process on the battery and the assessment of the special needs of the production process. The future trend and direction not only depend on The change of lithium-ion battery materials also depends on the production process.The roller compaction process ensures the desired compacted density of the lithium electrode sheet by presetting the gap size or the force between the two rollers at an appropriate roller speed and temperature. In order to increase battery capacity, improve electronic conductivity and electrochemical performance, lithium-ion battery pole pieces are produced by rolling technology.In-depth study and understanding of the evolution of the electrode microstructure during the rolling process, as well as the influence of process parameters on the final structure and performance of the electrode, will help to control the electrode more finely and improve the overall performance, which is of great importance to the design and production control of lithium-ion batteries meaning.

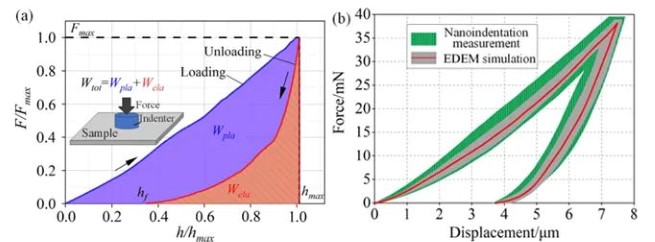

In 2022, Zhang et ¹ combined discrete element method numerical simulation and rolling test to carry out systematic microscopic and macroscopic research on the rolling process of the pole piece, and used the Heckel equation to supplement the electrode compression prediction model,Figure 1 is a schematic diagram of the stress and displacement curve of the pole piece during the compression process.It is clarified that the pole piece deformation is related to particle pulverization, secondary particle fusion, binder network compression and current collector surface deformation. At the same time, the findings show that the increase in electronic conductivity is related to the improved conduction path inside the electrode on the one hand and the tightening of the contact between the coating and the current collector on the other hand.Based on this research, this paper adopts BER2500 series pole piece resistance test equipment to test the conductivity of graphite pole pieces under different compaction densities, that is, different rolling pressures. At the same time, combining the flat pressing structure of the equipment to test and analyze the compression performance of the pole piece, it provides a new method for the evaluation of the lithium-ion battery pole piece rolling production process.

Figure 1. Schematic diagram of the force-displacement curve of the pole piece

(Green areas represent experimental results, gray areas represent simulation results)

Experimental Equipment and Test Methods

1.1 Experimental Equipmentd

The test equipment model is BER2500 (IEST), the electrode diameter is 14mm, and the applied pressure range is 5~60MPa. The device is shown in Figures 2(a) and 2(b).

Figure 2. (a) BER2500 exterior view; (b) BER2500 structure diagram

1.2 Sample Preparation and Test

1.2.1 After uniformly coating the slurry under the same process formula conditions, we use different pressures such as small, medium and large to carry out roll pressing to obtain four kinds of compacted finished pole pieces in 1/2/3/4 , wherein the pressure of the pole piece rolling is 1<2<3<4. The compaction density of the four pole pieces is calculated respectively by cutting-thickness-weighing method, and the compaction density also shows 1(1.35g/cm³)<2(1.5g/cm³)<3(1.6g/cm³)<3(1.6g/cm³) cm³)<4 (1.65g/cm³), that is, as the rolling pressure increases, the compaction density also shows an increasing trend.

1.2.2 Combining with BER2500 equipment, using the steady-state test mode, with 5-60MPa, 5MPa interval, and holding pressure for 15s, the compression and resistance of pole pieces with different compaction densities are compared and tested. The specific process of the test is: apply a certain pressure from 5MPa and keep it for 15s, the pole piece is compressed, and record the thickness and resistance of the pole piece at the same time; then increase the pressure at intervals of 5MPa, and then record the thickness and resistance of the pole piece, and so on until 60MPa; then gradually reduce the applied pressure to unload and record the thickness and resistance.

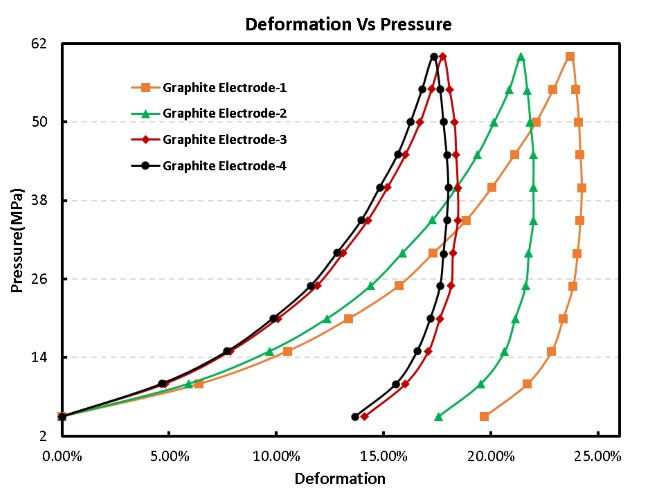

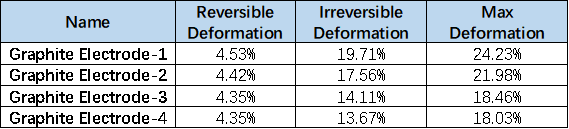

Data Analysis

After obtaining four electrodes with different compaction densities, use the steady-state mode to carry out loading compression-unloading rebound tests on the pole piece under different quantitative pressure conditions, record the thickness change, and use the initial pressure point of 5MPa as a benchmark to calculate the thickness deformation Perform normalized calculations to obtain the stress-strain curves of different pole pieces (as shown in Figure 3), and summarize their deformations (as shown in Table 1). It can be seen from the result chart that with the increase of the pole piece rolling pressure, the maximum deformation, reversible deformation and irreversible deformation of the four pole pieces gradually decrease (1>2>3>4), but the decreasing trend Gradually slow down. This change trend is closely related to the filling and compaction effect of the powder in the pole piece coating, including the flow and rearrangement of powder particles, elastic and plastic deformation, and crushing. Usually, the pole piece calendering process needs to overcome friction, surface force, elastic deformation, plastic deformation and crushing to do work on the electrode coating to compact the electrode.

The material formulation of the coating part designed in this experiment is consistent. Different rolling pressure will directly affect the flow and rearrangement of particles. The increase of rolling pressure can overcome the friction between particles and make the particles arrange more tightly and combine with each other. more closely. Moreover, as the rolling pressure increases, the powder first rearranges and fills the original hole; after the particles are in close contact, the pressure continues to increase, and the particles interact and elastically deform. When the pressure increases to the particle After a certain yield stress, the active particles undergo plastic deformation, which is also the key reason for the gradual increase in compaction density with the increase of rolling pressure. Lithium-ion battery pole piece formulations usually also need to add functional additives to the active powder, such as flow aids, binders, conductive agents, etc., which will also affect the change of the overall state of the pole piece under different pressures. In the actual pole piece production, the pole piece is affected by comprehensive factors such as process conditions, roller pressure, tension, speed and powder compression performance. The overall pressure set in the experiment in this paper is relatively small, but the compression performance trend is consistent with the actual production process, which can be used as an effective means of process evaluation.

Figure 3. Stress-strain (compression performance) curves of four kinds of pole pieces

Table 1. Summary of Four Kinds of Electrode deformation

During the rolling process of lithium-ion battery pole pieces, the deformation of the width and length of the pole pieces is very small, and the pole piece rolling can reduce the thickness of the coating, increase the compaction density, and improve the adhesion of the coating, so as to stabilize the electrode structure and improve purpose of battery capacity. The rolling process of the pole piece is a process in which the mass per unit area is almost constant and the volume is reduced. Between the particles, between the particles and the current collector, they are combined by a binder. The compression in the thickness direction of the pole piece is the result of the simultaneous compression of the current collector and the coating, but the change in the thickness of the current collector is relatively small. There is also interaction between the powder particles and the current collector. During the rolling process, the particles will form pits on the current collector, thereby increasing the contact area and cohesion between the coating and the current collector.

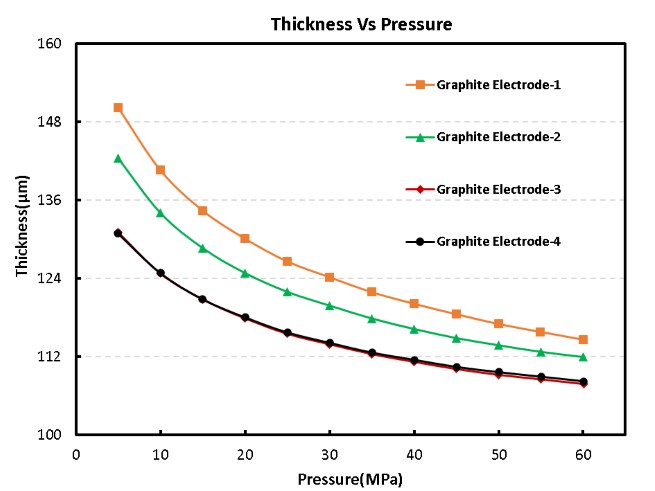

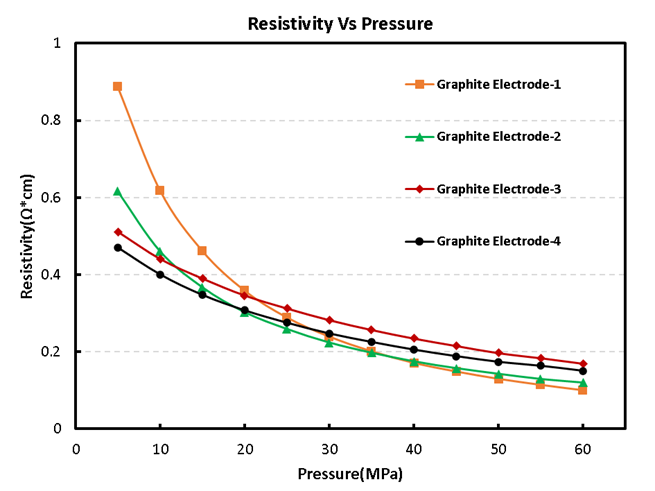

Figures 4 and 5 respectively show the thickness variation curves and resistivity variation curves of pole pieces with four different compaction densities under a series of pressure-applied flat pressures in the steady-state mode. As the pressure increases, the overall thickness of the pole piece becomes smaller as a whole. After a certain pressure, the thickness of the pole piece tends to be stable. At the same time, the pole piece is more likely to rebound when the pressure is low. Therefore, in the variable pressure test, the thickness varies greatly with the pressure. In the resistivity curve, the change trend of pole pieces 1 and 2 is greater than that of pole pieces 3 and 4. This is mainly because compared with pole pieces 1 and 2, the contact between the coating particles of pole pieces 3 and 4 under large rolling pressure and the The contact between the coating and the current collector is tighter, and the change in the overall thickness of the pole piece during the flat pressure measurement is smaller. Compared with the resistivity test results under different pressures, the absolute value of the small rolling pressure pole piece is smaller than the large rolling pressure, which may be because the change in the thickness direction of the flattened pole piece is easier to make the longitudinal conductivity of the pole piece better. In the actual evaluation of electronic conductivity, the most reasonable parameters can be selected for testing in combination with specific needs.

Figure 4. Thickness variation curves of four pole pieces

Figure 5. Conductivity test curves of four pole pieces

Summarize

In this paper, the BER2500 series pole piece resistance meter testing equipment is used to test the compression performance and conductivity of graphite pole pieces under different rolling pressures, which can effectively distinguish the performance differences of pole pieces under different rolling pressures. In the actual production process, the rolling pressure The selection of the battery should be reasonably selected in combination with the specific process formula. While increasing the battery capacity, it can also effectively improve the overall electrical performance of the battery.