Evaluation of the Resistance Performance of Charcoal-coated Aluminum Foil

As the carrier of conducting electrons and carrying active substances in the lithium-ion battery, the fluid collector plays an important role in the final performance of the battery cell.Aluminum foil is the most commonly used positive electrode fluid collection, in order to improve the electrode ratio, cycle and service life, on the aluminum foil surface coated with some conductive coating, can effectively improve the collecting fluid and active particles interface contact resistance, and improve the bond strength of the active material and fluid collection, reduce the active particles in the process of electrode cycle peeling problem.The coating of carbon aluminum foil generally usually includes conductive carbon black, graphene, carbon nanotubes, etc. The formula of carbon coating layer, coating thickness, and coating uniformity will also affect the bottom coating effect1.

This paper used the resistance test method of the electrode sheet, and analyzed the uniformity of the bottom electrode sheet.

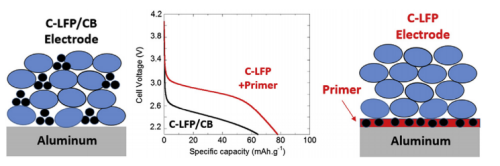

Figure 1. Schematic diagram of the influence of carbon coated fluid collector on cell performance1

I.Experimental Equipment and Test Methods

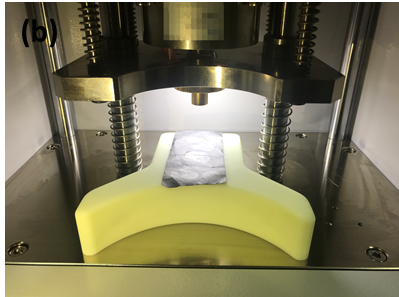

1.1 Experimental Equipment: Pole sheet resistor, model BER1300, electrode diameter of 14mm, can apply a pressure of 5~60MP a. Equipment is shown in Figure 2 (a) and 1 (b).

|  |

Figure 2. (a) BER1300 Appearance Diagram; (b) BER1300 Structure Diagram

1.2 Samples to be Tested: Bottom coating materials of three formulas, two coated aluminum foil with different thicknesses, empty aluminum foil, coated aluminum foil and pole sheet after applying active material.

1.3 Test Method: Cut the electrode piece sample to be measured into a rectangular size of about 5cm 10cm, place it on the sample table, set the parameters such as test pressure and pressure retention time on the M RMS software, and start the test. The software automatically reads the electrode piece thickness, resistance, resistivity, conductivity and other data.

2.Data Analysis

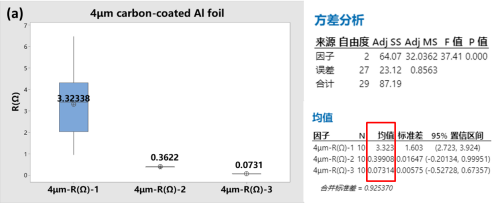

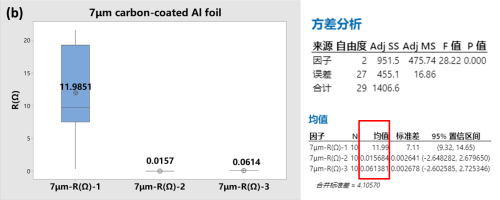

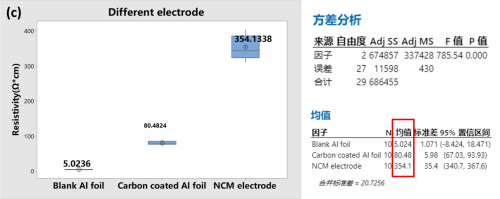

Testing of the different formulas of charcoal-coated aluminum foil, The thickness of the empty aluminum foil is all 10 m, The thickness of the two carbon coating layers were 7 m and 4 m, respectively, The tested pole sheet resistors are shown in Figure 3 (a) and (b), It can be found that the resistance of different formulations of charcoal-coated aluminum foil varies very much, Available from tens of m Ω ~ dozens of Ω, And judging from the uniform resistance of the different positions of the single pole sheet, The uniformity of charcoal-coated aluminum foil also varies greatly among different processes, Such as 4 m-R (Ω) -1 and 7 m-R (Ω) -1, It indicates that the poor resistance uniformity at different positions, This is too thin with the coating, There may be coating leakage or uneven distribution of carbon materials1.

According to the data in Figure 3 (c), the conductivity of the empty aluminum foil is the best one. When the carbon coating layer and the active material are added, the resistivity of the pole sheet tested by using the principle of two probes gradually increases, which shows that the addition of the coating will introduce the contact resistance between the particles, which weakens the conductivity of the electrons.Although it is generally believed that in the surface of aluminum foil increased coating layer will improve the electrical conductivity of the electrode, this is mainly due to the coating layer increased aluminum foil surface roughness, make the active material particles and fluid contact better, but if the thickness of the coating is thick or coating uniformity is too poor, but also can affect the conductivity uniformity of the active material coating electrode.

|

|

|

Figure 3. (a) foil resistance of carbon coating 4 m; (b) foil resistance of carbon coating 4 m; (c) electrode resistivity of three different states

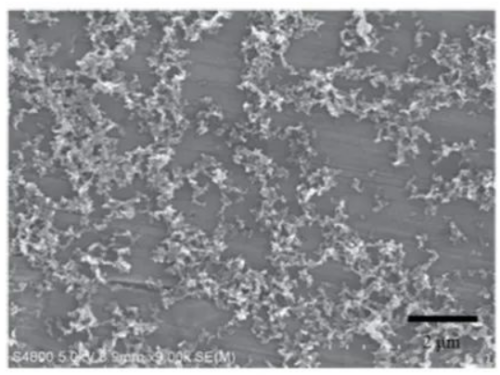

Figure 4. Schematic diagram of the surface morphology of carbon-coated black aluminum foil1

In a word, Adding an effective intermediate layer between the active material and the metal collecting fluid, In addition to improving the interfacial contact resistance, It also has the following potential synergistic benefits: (1) a chemically and electrochemically stable conductive layer can serve as an effective diffusion barrier, Preventing the diffusion of oxygen resulting from side reactions during electrolyte decomposition and / or lithium-ion embedding reactions, Effectively prevent the formation of oxide layers on the surface of the metal-collecting fluid, Thus prevent degradation; (2) the reasonably formulated conductive layer has good conductivity, Large areas of contacts can be formed, Low resistance at the fluid collector and active coating interface, This is conducive to the rapid charge transfer process; (3) The flexibility and mechanical buffer of the conductive layer can enhance the adhesion of the physical interface, Thus minimizing the related problems caused by the gradual loss of the contact area caused by the stress generated at the interface during the long-term cyclic reaction.By designing and developing unique conductive coatings, we experimentally demonstrate that the conductive interface layer can significantly improve the electrochemical properties, such as specific reversible capacity, capacity retention, multiplier performance, etc.

3.Summary

Charcoal aluminum foil is a kind of cathode fluid collection gradually selected by various battery manufacturers. The evaluation of different formulas and processes of carbon aluminum foil also plays an important role in the development of fluid collection.By testing the resistance parameters of the carbon-coated aluminum foil, it can help to assess the differences in the formula and the process, while also helping the lithium battery researchers to monitor the stability of the undercoating process.

Reference Documentation

1.Busson, C, Blin, M.A., Guichard, P., Soudan, P., Crosnier, O., Guyomard, D., & Lestriez, B.(2018).A primed current collector for high performance carbon-coated LiFePO4 electrodes with no carbon additive.Journal of Power Sources, 406, 7-17.

2.Chen Peng, Ren Ning, Ji Xuemin, et al.Application of charcoal-coated aluminum foil in lithium graphite / lithium iron phosphate batteries [J].New energy Progress, 2017,5 (2): 157-162.

3.Li Min, et al.Effect of coated carbon aluminum foil on the performance of lithium iron phosphate batteries [J].Energy Storage Science and Technology, 2020,9 (6), 1714-1719.