Electrode Sheet Resistance Test Method Inquiry-single Probe & Two Probe & Four Probes

Electrode as an important link in the battery production, the performance of the directly affect the stability of the process and the performance and safety of the cell, so the evaluation of pole performance, including Electrode resistance as an important index to evaluate Electrode performance, occupy an irreplaceable position in the battery development and production. The common methods for evaluating polar resistance include single probe method, two probe method, four probe method and multiple probe method, etc. The single probe method sets one end of the terminal and the other end connects the sample to test the resistance, the two probe method tests the terminal on the sample, and the four probe method puts four probes on the surface of the sample. This paper mainly explores the difference of foil and pole sheet resistance tested by single probe method and other test methods.

1.Experimental Equipment and Test Methods

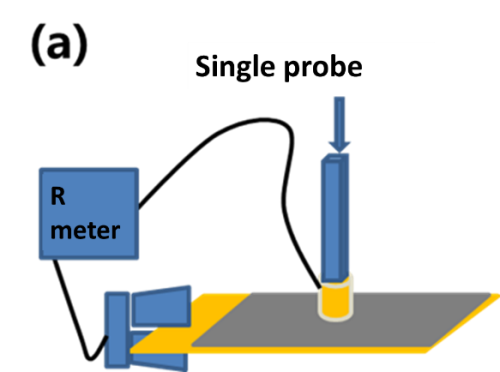

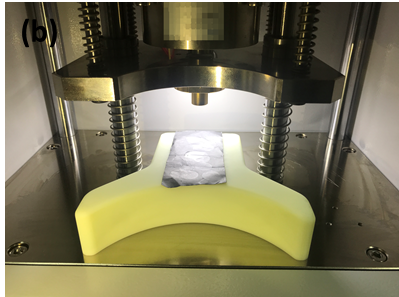

1.1 Experimental Equipment: the single probe device, as shown in Figure 1 (a), and the device for the two probes is as shown in Figure 1 (b).

|  |

Figure 1. (a) Single-probe method device (b) Structural diagram of the two-probe method

1.2 Test Method: the single probe method holds the resistor, and the other terminal moves the sample resistance; The controllable pressure single probe device holds one end on the controllable pressure device, and the other end sets the test pressure strength and retention time on the M RMS software, and the software will automatically read the data of electrode thickness, resistance, resistivity and conductivity.

2.Data Analysis

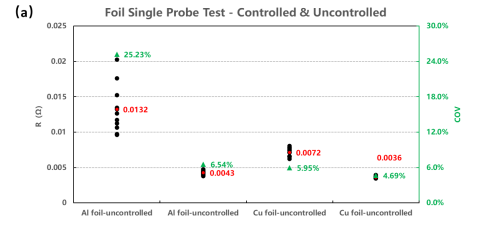

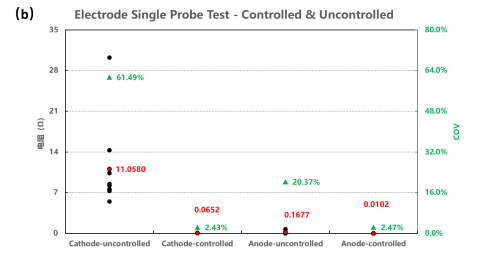

2.1 Resistance Comparison of Single Probe Pressure Control and Uncontrolled Pressure Test

Take aluminum foil, copper foil, positive plate, negative plate with two different single probe device test 10 sets of data, it can be seen from the figure, simple single probe method whether test foil or pole resistance, the COV value is greater than the controllable pressure, the maximum of more than 60%, the test resistance volatility is large, this is because the simple device single probe cannot fix the pressure, each test contact resistance is different, so the test error is greater than the controlled pressure device.

|

|

Figure 2.(a) Single probe-foil pressure control and uncontrolled piezoresistance contrast (b) Single probe-polar chip pressure control and uncontrolled piezoresistance contrast

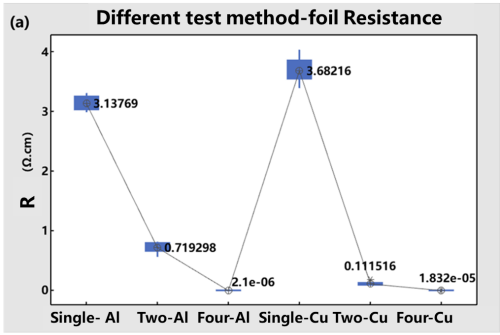

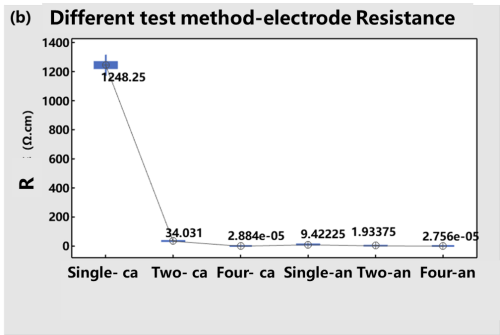

2.2 Comparative analysis of the resistivity of the test samples by single-probe method, two-probe method and four-probe method of controllable pressure. Aluminum foil, copper foil, positive plate, negative plate respectively with three different test methods to test 10 sets of data, as can be seen from the figure, for foil, resistivity comparison: single probe method> two probe method> four probe method, also for the polar plate resistivity, the trend is also a single probe method> two probe method> four probe method.

|

|

Figure 4. (a) Comparison of different test methods-foil resistivity chart (b) Comparison of different test methods-pole sheet resistivity

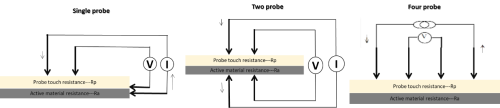

The difference in the resistivity measured by the three test methods was analyzed, which may be that the contact resistance between the probe and the electrode surface was different with the different methods, and the electron conduction path was not consistent with the different test methods. Single probe method of electron transmission path through the coating to the coating and the fluid interface, and then to the fluid, then through the lateral fluid to the other end of the test electrode,so more than the two probes a lateral fluid electron transmission, and the four probe test, separate current and voltage electrode, eliminate the wiring and probe contact resistance impedance, so the absolute value of the measured resistivity is the minimum.

Figure 5. Schematic Diagram of the three Measures

3.Test Principle Analysis

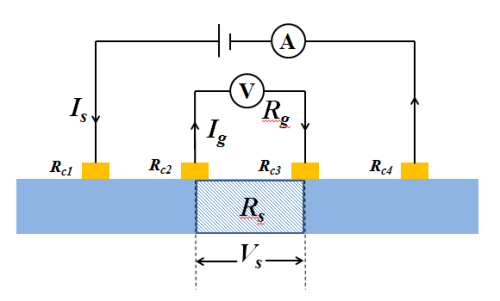

Figure 6. Schematic diagram of the four-probe method test

Figure 6 shows a schematic diagram of the test resistance by the four-probe method, assuming that the contact resistance of the four-terminal wiring and the probe are Rc1, Rc2, Rc3, and Rc4, respectively; the constant current source applies current Is (ammeter reading) to the sample through terminals # 1 and 4 #. If the resistance in the voltmeter is Rg, the voltmeter branch current is Ig, and the voltmeter voltage reading is Vg= Rg * Ig; the measured resistance between terminals 2 # and 3 # is Rs, then the measured resistance branch current is Is-I g, and the voltage of the measured resistance is V s; then:

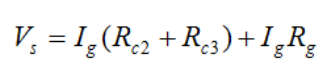

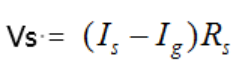

Calculated by the voltmeter branch, the voltage between terminals 2 # and 3 # is:

Calculated by the resistance branch to be measured, the voltage between terminals 2 # and 3 # can also be expressed as:

At this point, if there is Rg + Rc2 + Rc3>> Rs, then Is>> Ig, then Is Is-Ig,If Rg>> Rc2 + Rc3, there is V s Ig * Rg=Vg.

Then, the resistance is R =Vg / Is V s / (Is-Ig) =Rs that is calculated from the current and voltmeter readings. Therefore, the resistance calculated according to the current and voltmeter reading is almost equal to the actual measured resistance value, which is equivalent to testing the absolute resistance value of the sample to be tested. The resistivity of the material was then calculated based on the size specification of the probe and the test sample size.

In summary, the separate current and voltage electrodes used in the four-probe method eliminate the impedance of the wiring and the probe contact resistance. The key is that the resistance in the voltmeter is large enough, so that the branch current and the pressure drop of the line contact terminal can be ignored. The two probes for the voltage detection must be separated from the current source two probes. For the connection between the two probes for the voltage detection, all the main loop resistance between the two points will be included in the measured resistance. However, if the resistance of the sample to be tested is very large, it may be difficult to ensure that the resistance in the voltmeter is much greater than the sample to be tested, and that is, Rg + Rc2 + Rc3>> Rs may not be true, and the measurement results may have a large error.

Therefore, the four-probe method is often used to determine the absolute value of the electronic conductance of the battery electrode sheet because it eliminates the contact resistance between the probe and the sample (the compacted sheet or coating). Most four-probe methods choose to coat the slurry of the electrode material with a thin layer or an appropriate thickness on the insulation substrate, rather than the fluid-collecting material such as aluminum foil. This coating on the insulating substrate is designed to avoid tributaries in the substrate direction, thus accurately test the resistance of the electrode material. If the substrate is a fluid collector, the resistance of the coating, by adjusting the probe distance. However, the electrode coating in practical battery application is relatively thick (60~150 m), and the four-probe method only obtains part of the resistance contribution of the coating, while ignoring the coating gradient of the electrode, and cannot comprehensively represent the resistance value of the electrode. Moreover, the direction of the current transmission is parallel to the coating, which is different from the current transmission direction of the vertical coating in the actual battery, and the interface resistance of the substrate and the coating is also ignored, rather than the real situation of the polar sheet. And two probe method because the test results include probe, probe and coating contact resistance, so unable to measure the absolute value of electrode resistivity, and loading pressure and current test parameters affect the results, for high resistance of positive electrode, small load current can get stable results, and for low resistance of graphite electrode or foil, loading current is relatively high to get stable results. If the loading pressure increases and the resistivity of the foil or electrode decreases, the test results can be independent of the pressure. However, it contains some advantages: the electron conduction path of the test process is basically the same as that in the actual battery application. A total test value includes the electron conduction characteristics of the fluid collector, the fluid collector and the coating interface and each part of the coating itself, which can quickly study the influence of the formula and process on the resistivity of the polar sheet.

4.Summary

By exploring the difference of the resistance of the single-probe pressure control method and the uncontrolled pressure test samples, it is found that the pressure has a significant impact on the stability of the resistance data, so the tester must pay attention to the size and stability of the test pressure. Comparing three principles of test method to test the difference of sample resistivity, found that the measured absolute resistance difference is larger, from the application of practical pole and test operation convenience, suggest to choose the upper and lower two probe test the electrode penetration resistance, can quickly study the formula, process of electrode resistivity.