Electrode Resistance Test Method Comparison-four Probes Vs Two Probes

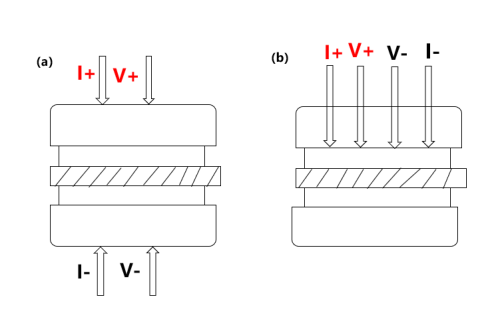

Lithium ion battery resistance is one of the important indicators to measure the battery performance, the size of the lithium ion battery resistance directly affects the lithium ion battery capacity, cycle life and safety performance, affect the factors of lithium ion battery resistance has electrode materials, formula, electrolyte, coating homogenization process, electrode resistance, etc., the electrode resistance reflects the electrode material performance and formula. Through the electrode resistance test results, on the one hand, it can be used to improve the homogenate coating process and formula to realize the rapid evaluation of the material system; on the other hand, it can timely screen and classify and eliminate the pole sheet with large resistance value, so as not to flow into the single manufacturing process, and improve the quality of terminal products. In this paper, the difference of the two test methods is tested by the method of four probes and two probes. The schematic diagram of the two test methods is as follows:

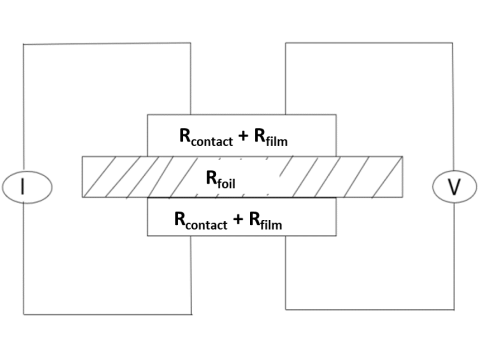

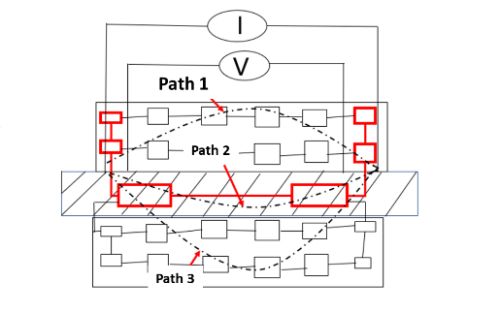

Figure 1. (a) Schematic of two probes (b) Schematic of four probes

During two probe tests, the terminal is placed on the sample and input the AC voltage signal to collect the current for the sample resistance and obtain the sample resistivity through the conversion relationship; the four probes are placed on the surface of the sample, and the voltage signal between the sample resistivity is obtained through the conversion relationship.

1. Experimental Equipment and Test Methods

1.1 Experimental Equipment: Pole sheet resistor, model B ER2500,electrode diameter of 14mm, can apply a pressure of 5~60MP a, the appearance of the equipment as shown in Figure 2.

|  |

Figure 2. (a) BER2500 appearance diagram (b) BER2500 structure diagram

1.2 Test Method: Set the parameters such as test pressure strength and pressure retention time on the M RMS software to start the test. The software automatically reads the electrode thickness, resistance, resistivity, conductivity and other data.

1.3 Sample Information: Select the positive electrode plate cathode-1, anode-1, the negative electrode sheet cathode-2, anode-2, pure membrane samples, aluminum foil and copper foil, and test the electrode plate resistance by two probes and four probes, respectively.

2. Data Analysis

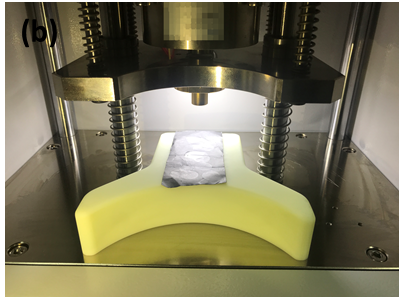

2.1 Test and Resistance Analysis of Strip Foil Pole Sheet

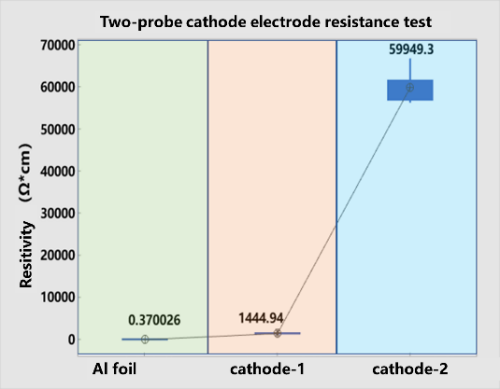

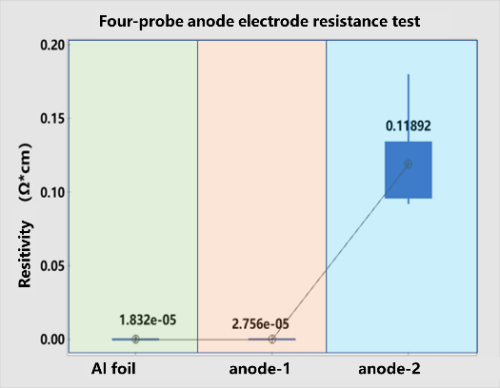

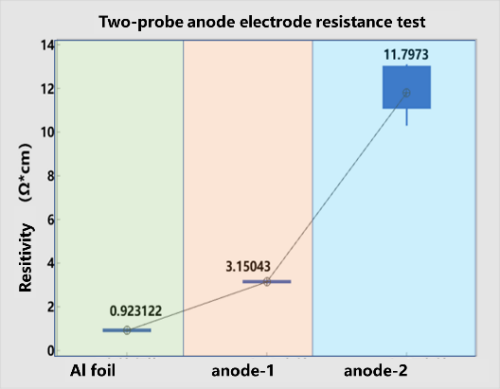

For the positive electrode sheet resistance test, Figure 3 (a) shows that for the small-resistance electrode sheet cathode-1 (2 ^ 10).1-6Ω * cm) with pure aluminum foil resistivity (2 ^ 10.884-5.3316.370026Ω * cm) varies by about 10 times, but for the electrode sheet cathode-2 with a large resistance value, the electrode resistivity of the four-probe test is 1 Ω * cm, which is much greater than that of the pure aluminum foil. In Figure 3 (b), the electrode resistivity tested by sheet cathode-1 (1444.94 Ω * cm) (0 Ω * cm), which also exceeds that of the foil, as shown in Figure 4 (a) and (b) shows the resistance between different coatings and the foil.

|  |

Figure 3. (a) Four-probe method positive electrode plate resistance test (b) Two-probe method positive electrode plate resistance test

|  |

Figure 4. (a) Four-probe method negative electrode plate resistance test (b) Two-probe method negative electrode plate

Resistance Test

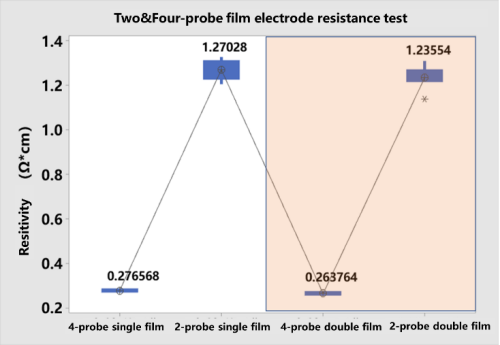

2.Analysis of Foil Pure Membrane Resistance

The resistance test of the dry-coated foil-free pure film sample is conducted by two methods. As can be seen from Figure 5, the resistivity of the monolayer test (0 Ω * cm) is almost the same as that of the bilayer test (0 Ω * cm), and is much greater than the resistivity of the pure aluminum foil (2 ^ 10).27.26.884-5Ω * cm) or pure copper foil (1.832 ^ 10-5.27.23Ω * cm), the resistivity of the single layer test (1 Ω * cm) of the two-probe method is almost the same as that of the double layer test (1 Ω * cm), but the resistivity of the two probes will be greater than that of the four-probe method.

Figure 5. Pure membrane resistance test by four probes and two probes

2.3 Mechanism Analysis

The equivalent circuit diagram of the two test methods is shown in Figure 6, Figure a represents the circuit diagram of the two-probe pole resistance, The figure shows that the current voltage is applied to the vertical ends of the sample, The result is the contact resistance of the polar sheet R, the R coating, the total resistance of the R collector fluid, Then the resistivity and the resistivity; Figure b is a schematic diagram of the circuit testing the electrode resistance by the four-probe method, The applied current is applied on the sample surface, So the current direction can be divided into paths 1,2, and 3, When the electrode sheet resistance is small, Electrons mostly pass through from path 2, Very arely through pathways 1 and 3, The measured pole sheet resistance is close to the foil resistance, When the sheet resistance is large, The probability of the electron passing through path 1 increases, The resistance value also increases, When testing the electrode sheet resistance by the four-probe method, Since the measured absolute value is small, Even getting up to the Ω level, The instrument accuracy, range and system pressure control and stability requirements are also high, It is therefore difficult to obtain stable data. In conclusion, it is appropriate to select the resistance of the composite layer.

|  |

Figure 6. (a) Schematic diagram of two probe circuit (b) Schematic diagram of four probe circuit

3.Summary

This paper compares the difference between the electrode resistance, the results show that test strip foil pole sample, four probe test resistance value is far less than the two probes, and sometimes the resistance is almost close to the resistance of the foil, unable to distinguish the coating, and because of the small value, instrument precision, range and system pressure control stability requirements is high, so it is difficult to get stable data, only test the coating without foil, resistance value in Ohm level. The two-probe test is the total penetration resistance of the electrode plate, which can significantly distinguish the difference of the coating, and is suitable for testing lithium batteries and all types of supercapacitors.

Reference Documentation

1. Hiroki Kondo et al.Influence of the Active Material on the Electronic Conductivity of the Positive Electrode in Lithium-Ion Batteries .Journal of The Electrochemical Society, 2019,166 (8) A1285-A1290

2. B.G.Westphal et al.In fl uence of high intensive dry mixing and calendering on relative electrode resistivity determined via an advanced two point approach.Journal of Energy Storage 2017, 11, 76–85

3. Nils Mainusch et al.New Contact Probe and Method to Measure Electrical Resistances in Battery Electrodes Energy Technol.2016, 4, 1550-1557