Analysis of Electrical Conductivity and Compaction Density of LMFP Material

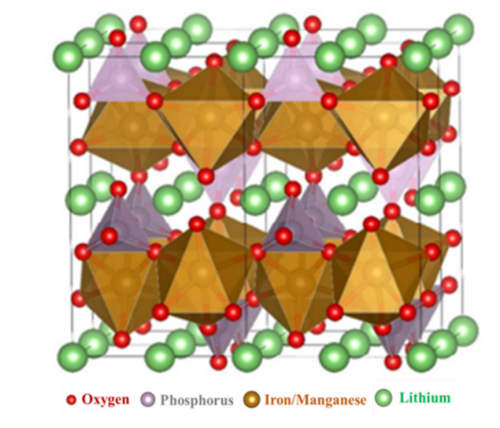

With the development of the new energy industry, lithium-ion batteries have gradually become a widely used power storage equipment.Among them, lithium iron phosphate battery is widely favored by the market because of its good safety performance, long cycle life, low price, rich raw material reserves and relatively small environmental pollution.However, the low lithium iron phosphate discharge voltage platform (~3.4V) and low energy density limit the development and application of lithium iron phosphate.With lithium iron phosphate (Li FePO4) Lithium manganese phosphate (LiMnPO) with the same structure4) relative to Li+The electrode potential of / Li is 4.1V, much higher than LiFePO4. The voltage platform.Lithium manganese iron phosphate (Li MnxFe1-xPO4) . It was done in the LiMnPO4On the basis of the modified iron doping form, formed with lithium iron phosphate (LiFePO4) . With the same olivine structure, stable structure and high voltage platform, it is a very potential new cathode material, see Figure 1 for lithium manganese iron phosphate (Li MnxFe1-xPO4) Schematic diagram of the crystal structure of the[1].

Figure 1. Lithium-manganese iron phosphate (Li MnxFe1-xPO4) Schematic diagram of the crystal structure of the[1]

It is reported that through the first principle calculation of electron energy level, the energy gap of electron transition in lithium iron phosphate (LiFePO4) is 0.3eV, with semiconductor characteristics, while the energy gap in lithium manganese iron phosphate (Li MnxFe1-xPO4) is 2eV, which is an insulator.In order to improve the poor conductivity of lithium manganese iron phosphate(LiMnxFe1-xPO4) , lithium manganese iron phosphate (Li MnxFe1-xPO4) material is usually prepared because carbon suppresses the growth of particles and reduces the diffusion distance of lithium ions. On the other hand, carbon has excellent conductivity, which is conducive to electron transmission and improves the electronic conductivity of the material. Lithium manganese iron phosphate(Li MnxFe1-xPO4) Materials, the conductivity and compaction density of different pressure conditions. At the same time, two materials with good conductivity are selected for compression performance test to evaluate their performance differences.

1.Test Method

1.1 PRCD3100 is used for conductivity and compaction density of five lithium manganese phosphate (LMFP-1, LMFP-2, LMFP-3, LMFP-4, LMFP-5), and compression properties of LMFP-4 and LMFP-5. Two probe modes are used for the test equipment, as shown in Figure 2.Test parameters: apply pressure range 10-200MPa, interval 20MPa, keep pressure for 10s;

|  |

Figure 2. (a) PRCD3100 appearance diagram; (b) PRCD3100 structure diagram

2.Test Results and Analysis

In the early development of lithium manganese iron phosphate, limited by its low conductivity and multiplier performance, the commercialization process is slow.With the progress of modification technologies such as carbon coating, nanotechnology and lithium filling technology, its conductivity has been improved to some extent, and the electrochemical properties of lithium manganese iron phosphate have been improved by controlling particle morphology, nano-chemistry and ion doping.

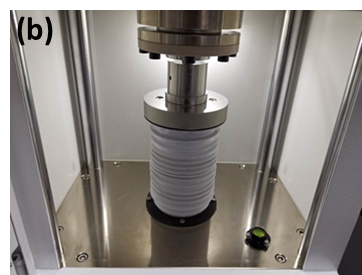

Material conductivity evaluation can be used as an effective way to evaluate material physicochemical properties.Figure 3 shows the resistivity test results of five different lithium manganese iron phosphate materials. From the resistivity test results, L MFP-4, L MFP-5 electron-conductivity samples are much better than L MFP-1, L MFP-2 and L MFP-3 samples. From the results of different materials, the material modification can effectively improve the poor conductivity of lithium manganese iron phosphate materials.In addition, the resistivity of the first three groups of L MFP increases with the increase of the test pressure, which may be due to the deterioration of the particles due to the deformation and crushing.

Figure 3. Resistivity test results of the five lithium manganese iron phosphate materials

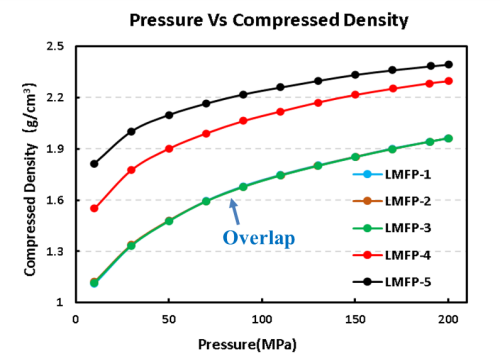

The material compaction density is closely related to the specific capacity, efficiency, internal resistance and battery cycle performance of lithium-ion battery. Figure 4 shows the compaction density test results of five lithium manganese iron phosphate materials. LMFP-1, LMFP-2 and LMFP-3 compaction density, while L MFP-4 and L MFP-5 improve the compaction density, the overall performance is required to obtain better overall performance.

Figure 4. Compaction density test results of the five lithium manganese iron phosphate materials

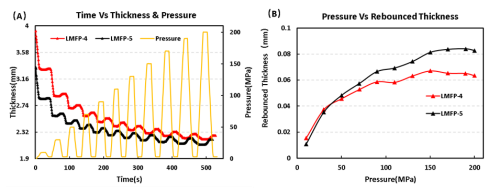

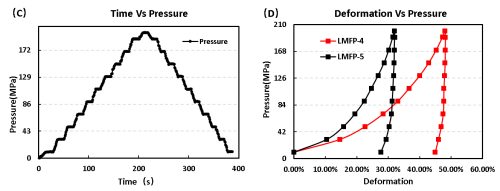

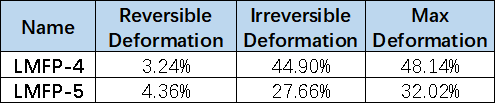

Pressure pressure and relief test of L MFP-4 and LMFP-5, following pressure change curve in Figure 5 (A), corresponding material thickness change and thickness rebound curve in Figure 5 (A) and (B).When the pressure of two LMFP powders were tested under the same sampling amount, the thickness rebound amount of LMFP-5 was greater than that of LMFP-4 material. At about 150MPa, the thickness rebound amount gradually stabilized. At this time, the pore between particles and particles has been basically excluded, and the difference in thickness rebound is mainly caused by the elastic deformation of the particles themselves.At the same time, Figure 5 (D) is used to obtain the stress strain curve in Figure 5 (C) by continuous pressure to keep the sample to the maximum pressure, as shown in Table 1, the compression deformation of LMFP-5 is slightly larger than LMFP-4; from the slope of the stress strain curve, LMFP-5 is larger than LMFP-4, indicating that it is more difficult to compress, which is consistent with the 5 (A) mode test result.The above test results can also show that the LMFP-4 can achieve a higher compaction density compared with the LMFP-5 material.

|

|

Figure 5. Stress and strain curves during compression and unloading of two LMFP materials

Table 1. Summary of Shape Variable Data for the Two LMFP Materials

3.Summarize

The powder resistance and compaction density (PRCD3100) equipment is used to detect the conductivity and compaction density. The test results show that the conductivity and compression density, with different compression properties, which is closely related to the material structure, can further realize deeper mechanism analysis with SEM and other test methods.The resistivity, compaction density and compression performance detection methods mentioned in this paper can be used as an effective material physical performance detection method to help researchers to quickly assess the difference in intermaterial conductivity and compaction density at the powder level.

4.Reference Documentation

[1] Tfyac E , Ying L, Zf D, et al.Improving the cycling stability and rate capability of LiMn0.5Fe0.5PO4/C nanorod as cathode materials by LiAlO2 modification.ScienceDirect[J].Journal of Materiomics, 2020, 6(1):33-44.

[2] Ma Guoxuan, Liu Rui, Liu Hongquan, et al.Study on cathode materials coated with lithium manganese iron phosphate [J].Journal of Shandong University of Science and Technology: Natural Science Edition, 2020,39 (6): 7.

[3]Dong D A, Ym A, Mk A, et al.Holey reduced graphene oxide/carbon nanotube/LiMn0.7Fe0.3PO4 composite cathode for high-performance lithium batteries .ScienceDirect[J].Journal of Power Sources, 449.