Literature Analysis Dispersibility and Electrochemical Performance Control of Slurry

1.Author Information and Article Abstract

In 2019, the Kentaro Kuratani team used the slurry viscosity and CT imaging characterization of different mixing methods to visually see the dispersion state of the slurry.Further combining with the rate performance of the button, it is found that the discharge capacity corresponding to the highly dispersible slurry is the lowest, indicating that the best dispersibility is not conducive to the battery capacity.

2.Experimental Information

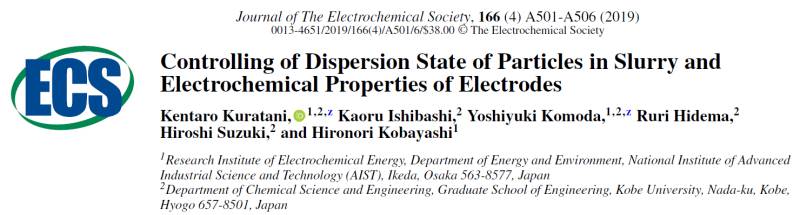

Three Kinds of Slurry Preparation Process

Figure 1. Slurry preparation process

3.Test Items

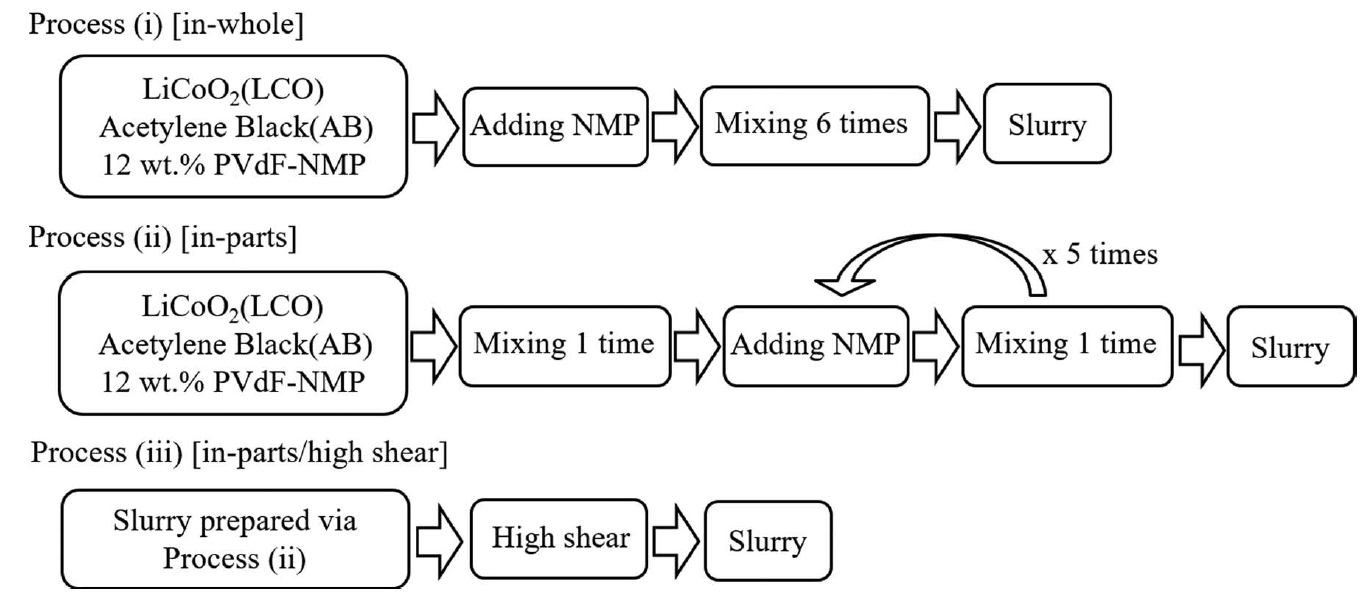

Slurry viscosity, CT imaging of pole piece, power rate performance.The CT three-dimensional imaging steps are shown in Figure 2.The final blue solid phase is LCO particles, and the pores represent several other materials.

Figure 2. Pole piece 3D imaging steps

4.Analysis of Results

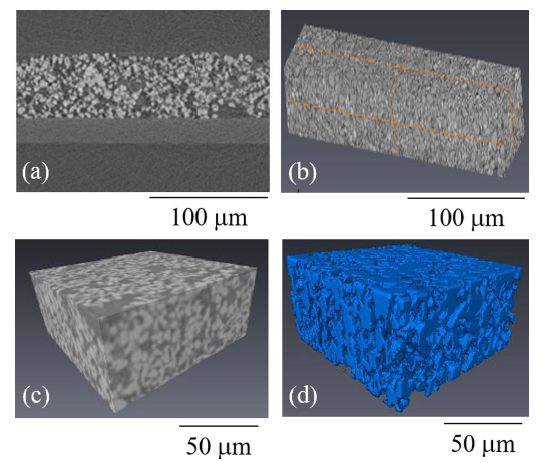

4.1 Slurry Viscosity of Three Mixing Processes

Comparing the viscosity curves of the three mixing processes, it can be found that there is no significant difference in the viscosity curves of the three at low shear rates (<1s-1). In the speed range of 1s-1~100s-1, the three kinds of viscosity decrease trends are different.Among them, the decline trend of the slurry viscosity in the in-part+high shear mode is greater than that of the other two.This may be related to the different particle dispersion states caused by different methods, which need to be further combined with the following characterization methods to analyze.

Figure 3. Slurry viscosity curves of three mixing processes

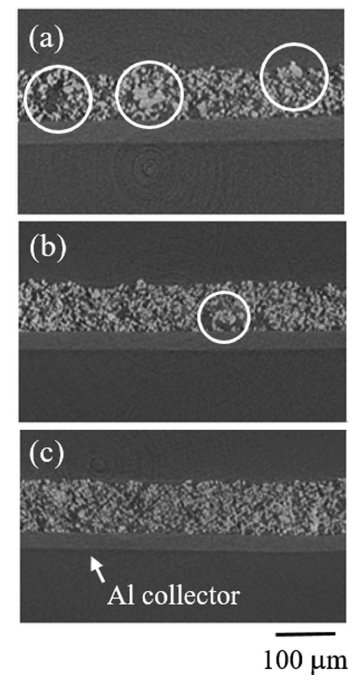

4.2 Pole Piece CT Imaging

It can be seen from the CT image that it can be seen from the CT image that in the pole piece coated with in-whole slurry, large particles are more agglomerated, and the second in-parts method has significantly reduced agglomerated particles.However, in the in-part+high shear method, there are almost no large particles agglomerated in the pole piece, which shows that the particle dispersion state of these three stirring methods is very different.

Figure 4. Pole piece CT imaging with three stirring methods

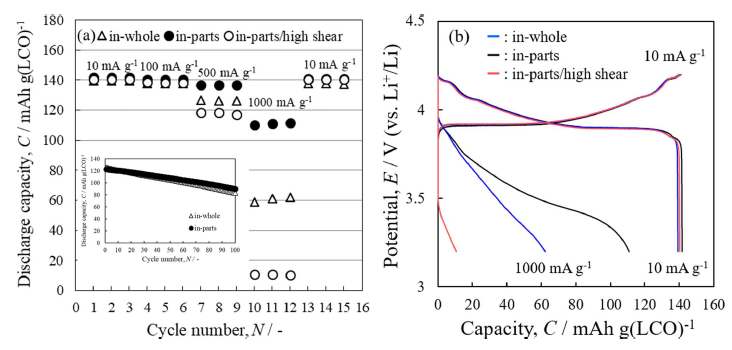

4.3 Buckle Electrochemical Performance

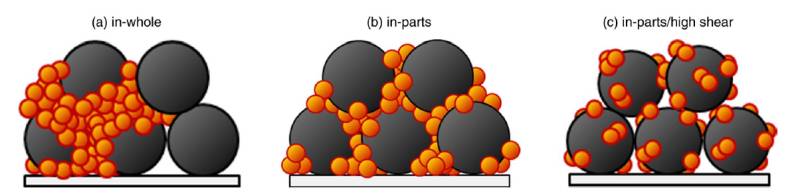

It can be seen from the discharge capacity data of different current densities that with the increase of the discharge current density, when the discharge current density reaches 1000mA/g, the capacity attenuation corresponding to the in-part/high shear stirring method is significantly greater than that of the other two. The discharge voltage curve also found that the voltage drop of this stirring method is the largest.Combined with the CT image of the pole piece, we can infer that the best dispersive agitation method will disconnect the conductive carbon network, and the electronic conduction of the pole piece will decrease. Therefore, the polarization will be larger and the capacity will decrease at high current density. When the cycle is continued with a small current density, the capacity of the three types of deduction is restored to the same.

Figure 5. The buckle rate performance of the three mixing methods

Figure 6. Schematic diagram of particle dispersion of three stirring methods

5.Summary

In this paper, through the characterization of the slurry viscosity and CT imaging of different stirring methods, the dispersion state of the slurry can be seen intuitively, and further combined with the rate performance of the deduction, it is found that the discharge capacity of the slurry with high dispersibility is the lowest.It shows that when the dispersibility is the best, it is not conducive to the battery capacity. This is mainly because when the dispersibility is the best, the conductive carbon network will be disconnected, the electronic conductance of the pole piece will decrease, the polarization will increase, and therefore the capacity will decrease.

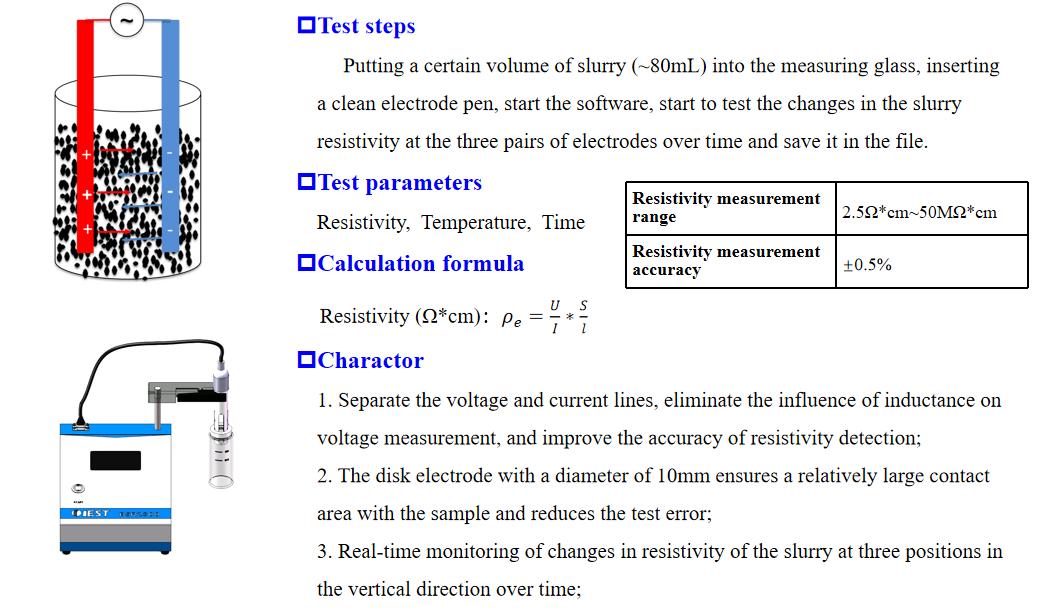

Recommended Test Equipment for IEST BSR Series Slurry Resistance Meter

6. References

Kentaro Kuratani, Kaoru Ishibashi, Yoshiyuki Komoda, Ruri Hidema, Hiroshi Suzuki and Hironori Kobayashi1. Controlling of Dispersion State of Particles in Slurry and Electrochemical Properties of Electrodes. Journal of the Electrochemical Society, 166 (4) A501-A506 (2019)