Study on the Correlation of Slurry Formula and Resistivity

Lithium battery positive and negative electrode slurry is a solid-liquid two-phase mixing system formed by the active substance, conductive agent and binder dispersed in the solvent. The ideal electrode slurry should meet the following requirements: (1) disperse the active substance and conductive agent particles aggregate as far as possible; (2) open the long chain of conductive agent to further disperse the chain conductive agent; (3) form the most suitable arrangement of active substance, conductive and binder; (4) maintain the optimal suspension structure and composition stability of the slurry and prevent settlement and agglomeration. The uniformity and stability greatly affect the consistency and electrochemical properties of the cell. If the solid particles are unevenly dispersed or rapidly settled in the solvent, a good electronic conductive network cannot be formed, which will greatly affect their electrical performance.

In the design of the lithium-ion battery electrode, the three-dimensional network formed by the conductive agent connects the active particles, which is the main path of electron transmission. Moreover, when the very low electron conductivity of the active substance, especially the cathode material, also needs the conductive agent to promote the electron conduction.

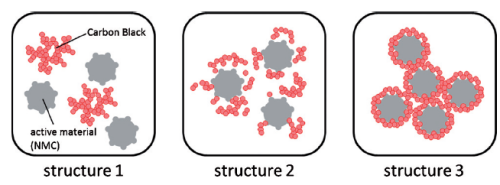

Therefore, in the design of lithium-ion batteries, we should select the matching conductive agent according to the different active material materials and different purposes (improving the multiplier performance, cycle performance, and improving the irreversible specific capacity). The material, morphology, particle size, mixing order, addition amount of the conductive agent and the compound state of different types of conductive agents all have different effects on lithium-ion batteries.in addition, The distribution state of the conductive agent is also critical, The possible distribution state of the conductive agent in the slurry is as shown in Figure 1: (1) the conductive agent gathers together, Not dispersed; (2) Uniform dispersion of the conductive agent, But individually suspended in the slurry, Not closely combined with the active material conductive agent; (3) Ideal distribution state of conductive agent in the slurry: uniform dispersion of conductive agent, Form a thin conductive layer on the surface of the active material particles; The conductive agent is in close contact with the surface of the active material particles, Enabling electrons to effectively participate in the removal / lithium embedding reaction; The conductive agents are connected with each other, Form an electron pathway with each active material particle.

Figure 1 Distribution status of the conductive agent in the slurry

Measure the resistivity of the slurry can assess the dispersion and conductivity of the particles at the slurry level. At present, conductive agent studies the model of conductive network, but quantitative analysis of resistivity is rare. This paper analyzes the relationship between solid content, resistivity, and viscosity, and verifies the conductivity type of positive and negative electrode by changing the current-voltage curve.

1 Test Method

1.1 Test Equipment: the BSR2300 is used to represent the positive and negative electrode paste resistivity with different solid content and viscosity.

Figure 2. BSR2300 Appearance Diagram

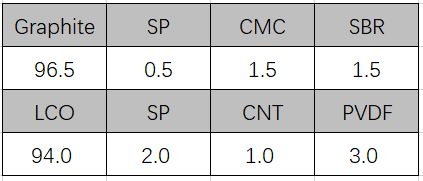

1.2 Slurry Ratio

Table 1 Slurry Ratio

2 Test Results

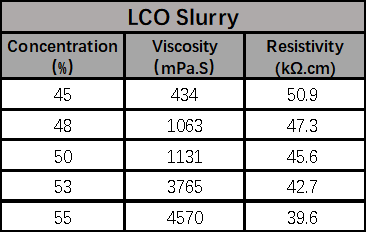

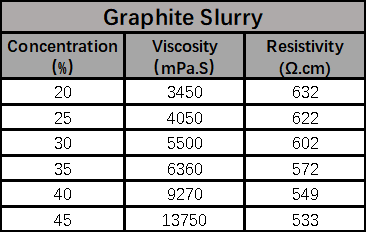

According to the formula of Table 1, the positive and negative electrode paste with different solid content are configured respectively to test the viscosity and resistivity respectively.

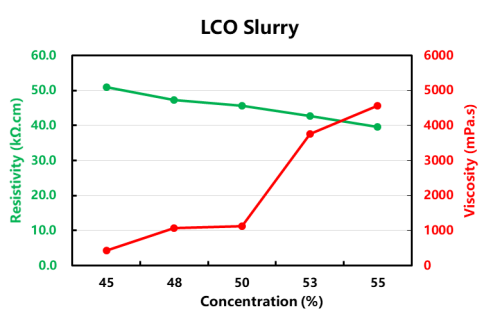

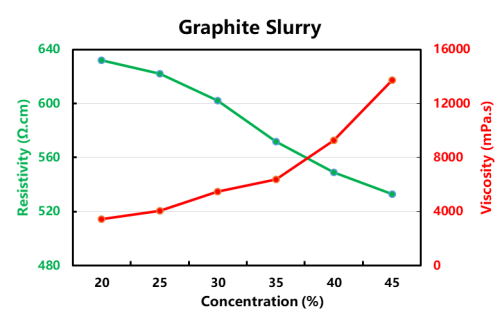

As shown in Table 2, the viscosity of the positive and negative electrode paste increases with the increase of the solid content, while the resistivity is constantly decreasing. As shown in Figure 3, when the L CO solid content is greater than 50%, the viscosity rises sharply, this may be because as the solid content increases, lithium cobalt oxide particles per unit volume is increasing, high density of lithium cobalt oxide particles collision will aggravate the interaction force between the particles in the system, resulting in viscosity increase, and sharply increase point for the threshold point between particles. As shown in Figure 3, when the solid content of graphite is below 35%, the resistivity decreases as the solid content increases, and when the solid content is greater than 35%, the resistivity changes slowly with the solid content, because as the solid content increases, more and more particles build effective conductive networks, and the conductivity does not increase significantly when the valve value is reached.

Table 2. Solid Content & Viscosity & Resistivity of Positive and Negative Electrode Slurry

|  |

|

|

FIG. 3 Resistivity and Viscosity of Positive and Negative Electrode Paste Change Trend with Solid Content

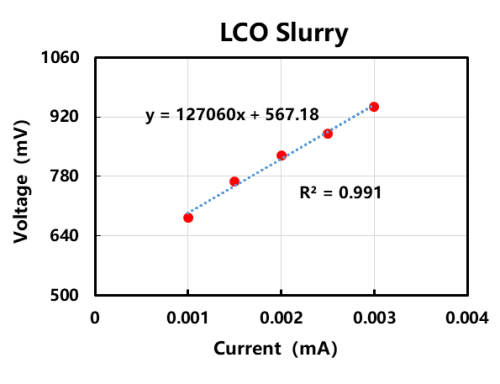

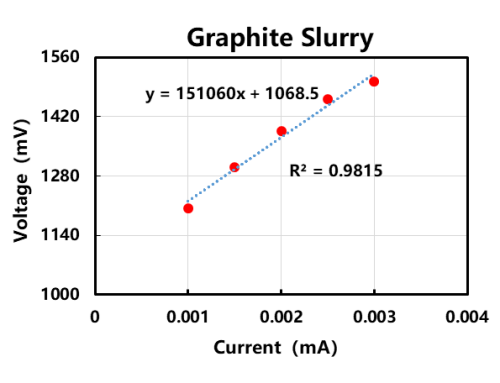

In order to further study the electrical conductivity mode in the lithium battery positive-negative electrode slurry system, the I-V experiment was designed to verify it, as shown in Figure 4. The 0.001mA, 0.0015mA, 0.002mA, 0.0025mA, 0.003mA current was applied to the lithium cobalt oxide paste and the graphite paste respectively, and the voltage signal was collected. Figure 4 shows that the linear relationship between current and voltage is obvious. The basic composite Ohm law shows that the conductive types of lithium cobalt oxide positive paste and graphite negative paste are mainly electronic conductance, that is, the electrons are transmitted to the particles themselves through the contact between the particles, and then build a multi-dimensional conductive network, showing a certain conductive performance.

|

a a |

Figure 4. Material I-V curve

Sum Up

In this paper, BSR2300 was used to analyze the relationship between the resistivity, viscosity and solid content of lithium battery positive and negative electrode paste, and found that the resistivity of positive and negative electrode paste is significantly reduced with the increase of solid content. Meanwhile, through the I-V curve to prove that the lithium battery positive and negative electrode paste system is based on electronic conductance.

Reference Documentation

1. B.G.Westphal et al.Journal of Energy Storage 11 (2017) 76–85.

2. Kentaro Kuratani et al.Journal of The Electrochemical Society, 166 (2019) (4) A501-A506.