Current Status and Expansion Test Evaluation of Silicon-Based Anode Market

Market Status

With the vigorous development of the new energy industry, lithium-ion batteries are gradually developing in the direction of higher energy density and longer cycle life. The theoretical gram capacity of the existing graphite negative electrode is only 372mAh/g, which can no longer meet the demand for battery energy density in the future. Due to its high theoretical gram capacity, rich content, and high lithium intercalation potential, silicon-based negative electrodes have gradually become the next-generation lithium battery negative electrode materials that can replace graphite.

At present, the main development directions of silicon-based materials are silicon-carbon composites and silicon-oxygen composites. The silicon carbon material is simple silicon as the matrix and then compounded with carbon materials, the silicon-oxygen material is made by gas-phase-precipitating elemental silicon and silicon dioxide (SiO2) at high temperature, so that silicon nanoparticles are uniformly dispersed in the silicon dioxide medium to prepare silicon oxide (SiO), and then compounded with carbon materials.

According to GGII data, in 2021, about 11,000 tons of silicon-based anodes will be shipped after recombination. Compared with the shipment of 740,000 tons of anodes, the penetration rate is only 1.5%, in 2022, the shipment volume of silicon-based negative electrodes will rise to 16,000 tons after recombination. It predicts that in 2023, the shipment of silicon-based negative electrodes after compounding is expected to exceed 27,000 tons, and the compound growth rate in the next three years is expected to exceed 60%. At present, silicon-based negative electrodes are mainly used in the field of electric vehicles (represented by Japan and the United States) and electric tools (represented mainly by South Korea). From 2020, a gradual application trend will begin to form in consumer digital and wearable products. In recent years, power battery companies represented by Tesla have been expanding the application of silicon materials, and the follow-up 4680 large cylinder power will accelerate the application of silicon-based negative electrode materials. Table 1 shows the progress in the application of silicon-based anodes in major car companies and battery factories.

Table 1. Application progress of car companies and battery factories on silicon-based anodes

Car Companies/ Battery Factories | Timeline | Specific Progress | |

Tesla | 2017 | Tesla uses a Panasonic 21700 battery. The negative electrode material is 10% silicon-based material (silicon oxide) added to artificial graphite. Its capacity is above 550mAh/g, and the battery energy density can reach 300wh/kg. | |

GAC | 2021 | GAC released a single battery cell using sponge silicon negative battery technology. The energy density of the battery cell exceeds 280Wh/Kg, and the cruising range exceeds 1000Km. GAC Aian LX equipped with this battery will be mass-produced within this year. | |

NIO | 2021 | In January 2021, NIO launched a 150kWh battery pack. The NIO ES8 equipped with this solid-state battery pack will have a cruising range of 730 kilometers, and the maximum cruising range will reach 910 kilometers. The delivery will begin in the fourth quarter of 2022, in which the negative electrode is made of homogeneous coating and inorganic pre-lithiated silicon-carbon composite negative electrode material. | |

IM | 2022 | In terms of battery life, IM L7 is equipped with a standard 93kWh battery, with a cruising range of 615km. The high-end configuration uses a 118kWh battery, and adopts silicon-doped lithium supplementation technology, which can achieve a single energy density of 300Wh/kg. NEDC has a battery life of nearly 1000km.L7 is expected to be delivered in the first half of 2022, and silicon-carbon anode batteries are expected to be introduced to the market in the next 5 years. | |

Benz | 2025 | In 2025, Mercedes-Benz will adopt a new generation of high-energy-density batteries in the G-Class model. By using silicon-based negative electrodes, the energy density is 20%-40% higher than that of current graphite negative electrodes, the battery is provided by Ningde Times, and the anode material is from Sila Nano, a California start-up company. | |

CATL | 2021 | In 2020, we will jointly develop the "silicon-doped lithium battery cell" technology with IM; in 2021, we may supply NIO's 150kWh solid-state battery, which uses silicon-carbon negative electrode of inorganic pre-lithiation process. | |

BYD | 2022 | In 2022, it will strategically invest in Dow Technology’s 6 billion-plus silicon-carbon anode material project; at the same time, it said that it has technical reserves and uses silicon-based materials as the anode of solid-state batteries, and the energy density is expected to reach 400Wh/kg. | |

Gotion | 2021 | In January 2021, Gotion officially released a soft-packed lithium iron phosphate battery cell with an energy density of 210Wh/kg, and claimed to have successfully applied silicon negative electrode materials for the first time in the lithium iron phosphate chemical system. | |

LISHEN | 2017 | In 2017, it undertook the national project "High Specific Energy Density Lithium-ion Power Battery Development and Industrialization Technology Research” and completed the development of a single power battery with an energy density of 260Wh/kg, and the capacity retention rate reached 83.28% after 350 cycles, the battery uses a silicon-carbon composite. | |

Panasonic | 2017 | Tesla uses a Panasonic 21700 battery. The negative electrode material is 10% silicon-based material (silicon oxide) added to artificial graphite. Its capacity is above 550mAh/g, and the battery energy density can reach 300wh/kg. | |

Samsung SDI | 2021年 | In 2021, it is planned to launch the second-generation battery silicon-based anode with a silicon content of 7%, and the third-generation battery with a silicon content of 10% is expected to be released in 2024. | |

Expansion Test Evaluation

The expansion problem of silicon-based negative electrodes is the biggest obstacle to the application of silicon-carbon negative electrodes in a large range. The huge volume change brought about by the expansion will, on the one hand, cause the internal stress of the electrode to accumulate, causing the electrode to pulverize, reducing the cycle performance and safety of the battery, on the other hand, the volume change also makes the SEI film of the negative electrode need to be formed repeatedly, which leads to the loss of active lithium source and reduces the first Coulomb efficiency. The lithium storage mechanism of the silicon-based negative electrode is alloyed lithium storage. Unlike graphite intercalation lithium intercalation, silicon particles will cause huge volume expansion and contraction in the process of alloying/de-alloying, when silicon and lithium form the Li15Si4 phase, the corresponding maximum volume expansion can reach 300%; the addition of oxygen atoms limits the reaction depth of the silicon-oxygen negative electrode. Although the expansion rate can be reduced to 120%, it is still far greater than the 10%-12% of the graphite negative electrode. The huge volume expansion will lead to the pulverization of the silicon material particles, which will make the electrical contact between the silicon particles and the conductive agent worse; second, it will lead to continuous rupture and regeneration of the SEI film. This process will consume a large amount of active lithium and electrolyte, thereby accelerating the capacity decay and aging of the battery.

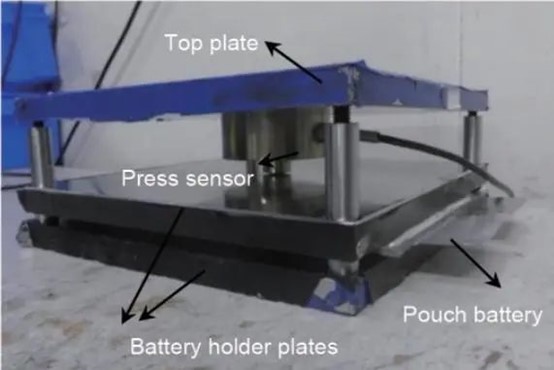

How to accurately characterize the expansion thickness of silicon-based anode batteries at different time points during the charging and discharging process is a major difficulty that plagues material factories and battery factories, at present, the expansion methods for measuring the scale of the pole piece and the scale of the battery mainly include the measurement of the micrometer, the measurement of the film thickness gauge, the measurement of the laser thickness gauge, and the measurement of the manufacturing tooling and the pressure sensor. Researchers from Hefei Gotion High-tech Power Energy Co., Ltd. used German Mahr Millimar C1216 to study the effect of binder on the expansion of lithium-ion battery negative electrodes [1]. Researchers from Tsinghua University used laser thickness measurement to study the deformation of the soft-pack battery pole pieces and cells [2]. The School of Energy of Soochow University cooperated with the researchers of Ningde New Energy and used a self-made test device with a pressure sensor to test the expansion force of the pouch battery during charging and discharging under a constant gap. The device used is shown in Figure 1 [3].

Figure 1. Expansion Stress Test Setup

Among the above methods, the in-situ test cannot be done by using a micrometer, a film thickness gauge, or a laser thickness gauge to measure the expansion thickness of the pole piece. It is necessary to dismantle the battery after charging and discharging, and take different points for measurement, it will cause large deviations in the results and cannot accurately reflect the thickness changes of the pole piece during the charge and discharge process. The method of fitting the tooling with the pressure sensor can only measure the expansion force of the battery under a constant gap, but cannot measure the real-time expansion thickness of the battery. To more accurately measure the thickness change of the silicon-based negative electrode material during the charge and discharge process, researchers from Tsinghua University and Tianjin Lishen Battery independently designed and built a set of in-situ optical microscopic testing system, which can observe the thickness and state of the pole piece or battery in situ with an optical microscope [4].

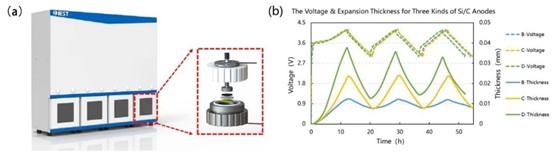

Based on the actual testing requirements of silicon-based negative electrodes and the advantages and disadvantages of different testing methods, IEST independently developed the in-situ swelling analysis system (SWE2110, IEST) and the in-situ rapid swelling screening for silicon-based anode(RSS1400, IEST).It uses model button cells to perform in-situ swelling tests at the pole piece level, at the same time, the in-situ cell expansion test can be carried out on pouch batteries with a certain thickness, which is not only convenient to operate, but also greatly saves the test cost, and shortens the evaluation cycle of silicon-based material expansion from the original dozens of days to 1-2 days . The physical picture of RSS1400 is shown in Figure 2(a), and the expansion comparison results of silicon carbon materials with different structural designs are shown in Figure 2(b).

Figure 2. (a) The in-situ rapid swelling screening for silicon-based anode (RSS1400, IEST)

(b) Swelling comparison of SiC materials with three different structural designs.

Summary

With the rapid development of lithium-ion batteries, the application coverage and market share of silicon-based negative electrode materials are also increasing year by year. The expansion of silicon-based negative electrodes is a key factor hindering its rapid development, the effective monitoring of the current material expansion inhibition modification and cell layer expansion is also the focus of industry development, IEST RSS series the in-situ rapid swelling screening for silicon-based anode is a specialized equipment developed for monitoring the expansion of silicon-based materials, it can be combined with the pole piece level to quickly realize the rapid evaluation of different process modified materials, which can be used as an effective means for material development and incoming material monitoring.

Reference Literature

[1] He Yuyu, Chen Wei, Feng Desheng, Zhang Hongli. Effect of Binder on Lithium-ion Battery Negative Electrode Swelling [J]. Battery, 2017,47(03):169-172.

[2] Zhang Zhengde. Research on the deformation of lithium-ion flexible packaging batteries [D]. Tsinghua University, 2012.

[3] Niu Shaojun, Wu Kai, Zhu Guobin, Wang Yan, Qu Qunting, Zheng Honghe. Expansion stress of silicon-based negative electrode in lithium-ion battery during cycling [J]. Energy Storage Science and Technology, 2022,11(09):2989- 2994.

[4] Jinhui GAO, Yinglong C, Fanhui M, et al. Research on in-situ optical microscopic observation in lithium-ion batteries[J]. Energy Storage Science and Technology, 2022, 11(1): 53.