IEST Lithium Battery Electrode Testing Scheme

Electrode Uniformity

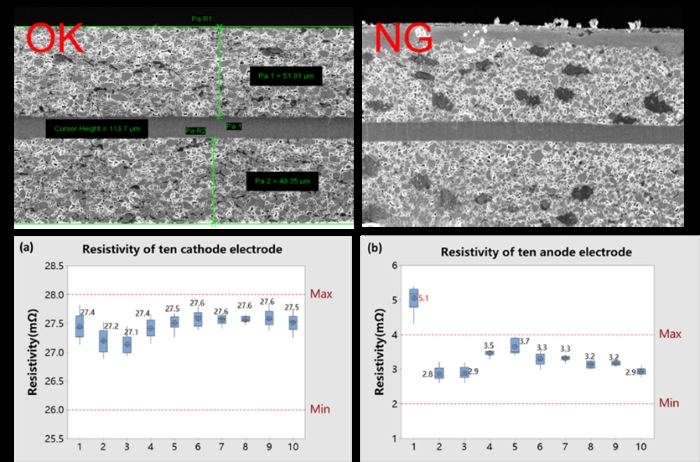

In the manufacturing process of energy storage batteries, the uniformity of electrode coating is an important parameter to be monitored in the early stages of cell production. It is also one of the crucial properties that affect the cycling performance and consistency of energy storage batteries. The coating process stage involves many process parameters, and each parameter can have different effects on the coating uniformity of the electrode. For example, in terms of slurry characteristics, the electrode slurry consists of micrometer-sized active solid particles and nanometer-sized conductive agent particles suspended in a binder solution. Solid particles are subject to forces such as gravity, Brownian motion, and buoyancy, leading to processes like settling, random Brownian motion, and aggregation-disaggregation. As a result, the distribution state of slurry conductive agents and active particles, as well as their interactions, inevitably undergo changes, which can affect coating uniformity.

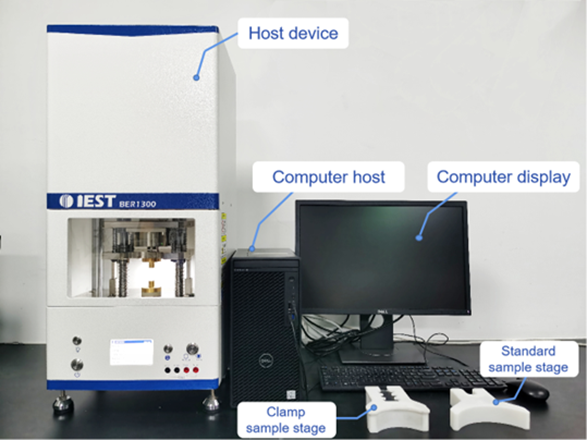

The dispersion of main materials, conductive agents, and binders in the positive and negative electrode sheets of energy storage batteries is influenced by numerous complex process control parameters mentioned above. Non-uniform material dispersion can significantly deteriorate the dynamic performance of the cell, but it is often difficult to detect through conventional monitoring methods such as electrode appearance or adhesion strength. It is frequently overlooked, leading to irreparable losses. Using the IEST BER series electrode resistance tester for monitoring the changes in electrode resistance across different batches or locations can quickly identify process variations at the electrode ends. This aids in quality control in the battery cell production process and provides an effective means for process validation.

Electrode Compression Modulus

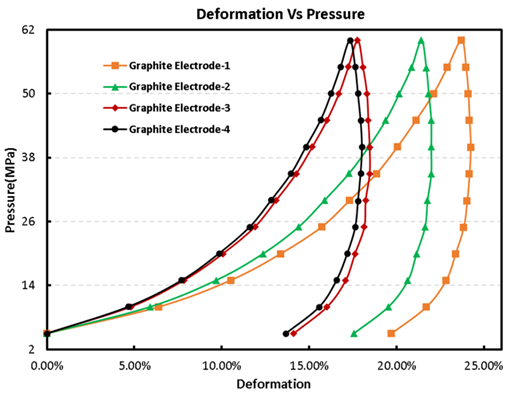

The compression modulus of the electrode is a critical parameter that energy storage battery cell designers and manufacturing process engineers focus on. If the rebound design of the energy storage cell is not accurate, it may result in poor cell appearance, leading to scrapped products. If the final product's thickness rebound design is not accurate, it may lead to cells being either too thick or too thin, failing to meet customer requirements.

IEST's self-developed electrode resistance tester (BER2500) can be used to measure the compression modulus and thickness rebound of electrodes. As shown in the figure, we selected four electrodes with different compaction densities for compression modulus validation. It can be observed that as the roller pressure on the electrodes increases, the maximum deformation, reversible deformation, and irreversible deformation of the four electrodes gradually decrease (1 > 2 > 3 > 4), but the rate of decrease gradually slows down. This changing trend is closely related to the filling and compaction effects of the powder particles in the electrode coating, including the flow and rearrangement of powder particles, elastic and plastic deformation, and fragmentation. Typically, the electrode calendaring process involves overcoming forces such as friction, surface tension, elastic deformation, plastic deformation, and breakage to compact the electrode coating. Inadequate selection of compaction density not only affects the stability and yield of the mid-assembly process in energy storage batteries but also influences the expansion of the cell and the electrochemical performance of lithium batteries in the later stages.