IEST Supports Scientific Research-Investigation of Silicon-Based Lithium-Ion Battery Performance under Different External Pressures

Investigation of Silicon-Based Lithium-Ion Battery Performance under Different External Pressures

Author Information and Article Abstract

Recently, Tan Peng's research group at the University of Science and Technology of China (first author Zhiyuan Zhang) explored the impact of external pressure on the polarization and cycle performance of silicon anode lithium batteries and found that appropriate external pressure can reduce the polarization of the battery cell during cycling. , and applying stepped external pressure during battery cycling can significantly improve cycle life. The research results can be used as an effective strategy to increase the capacity of lithium-ion batteries based on silicon-based negative electrodes and guide the process design of battery packs.

Experimental Plan

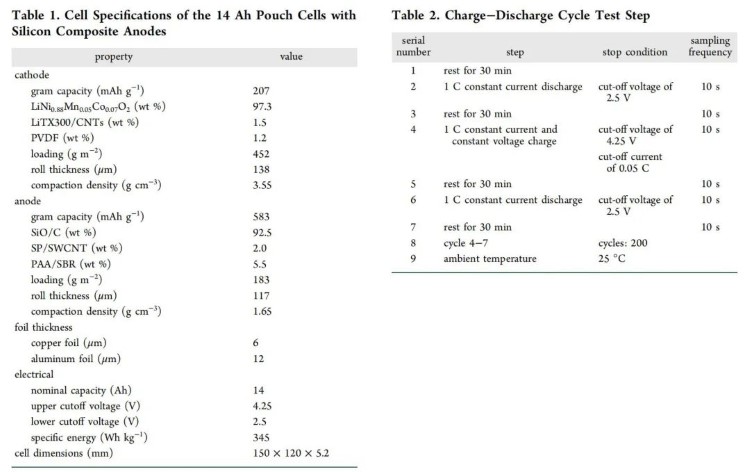

1. Battery core design system and charge and discharge conditions: as shown in the table below.

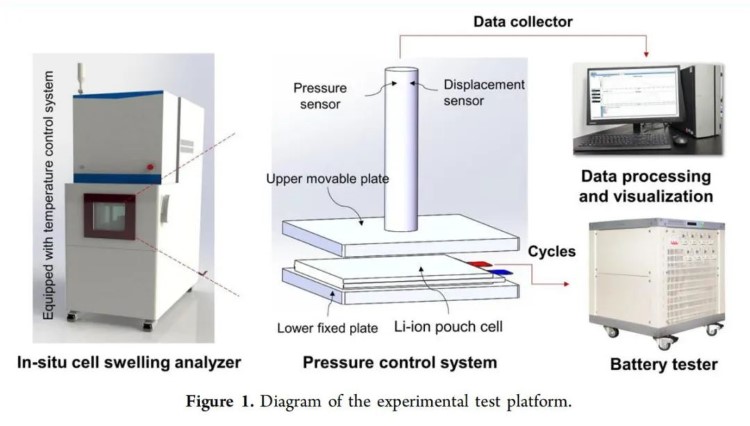

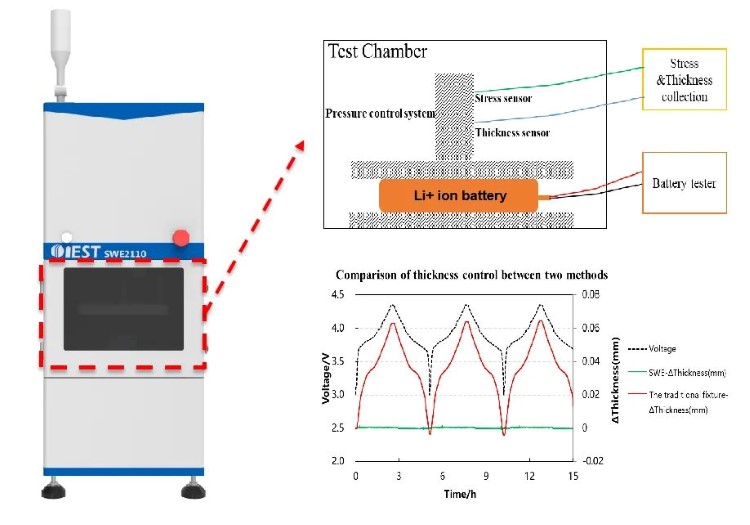

2.High-precision In-situ Swelling Characterization Equipment: IEST-SWE2100 in-situ swelling equipment is used to apply precise external pressure to the cell and detect thickness swelling.

Visual and Textual Analysis

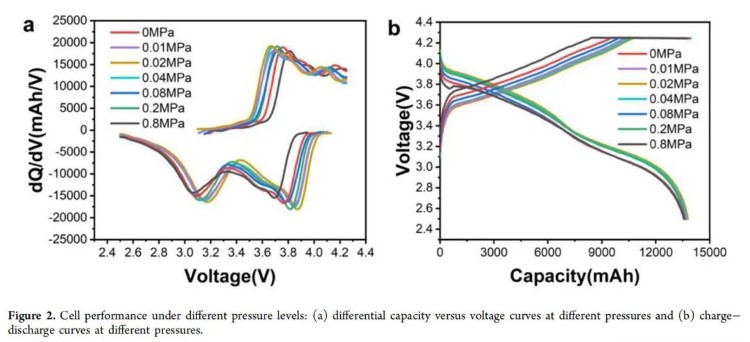

The author explored the impact of polarization on the charge and discharge process by changing the external pressure exerted on the surface of the battery core. It was found that as the pressure increased, the peak position of the differential capacity curve first moved to the left and then to the right, among them, the battery core corresponding to 0.02MPa has the smallest polarization, indicating that this pressure is the most suitable test condition.

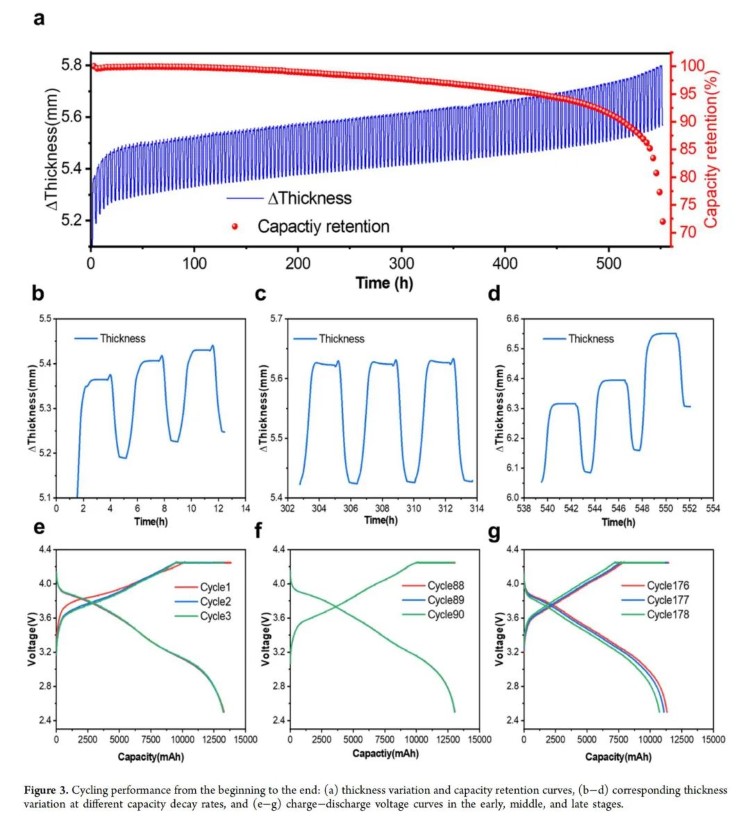

Continue to explore the cycle life of the battery core under the external pressure of 0.02MPa. As the cycle progresses, the expansion thickness trend of the battery core has three stages: rapid growth, slow growth, and rapid growth. This phenomenon corresponds to the capacity attenuation trend.

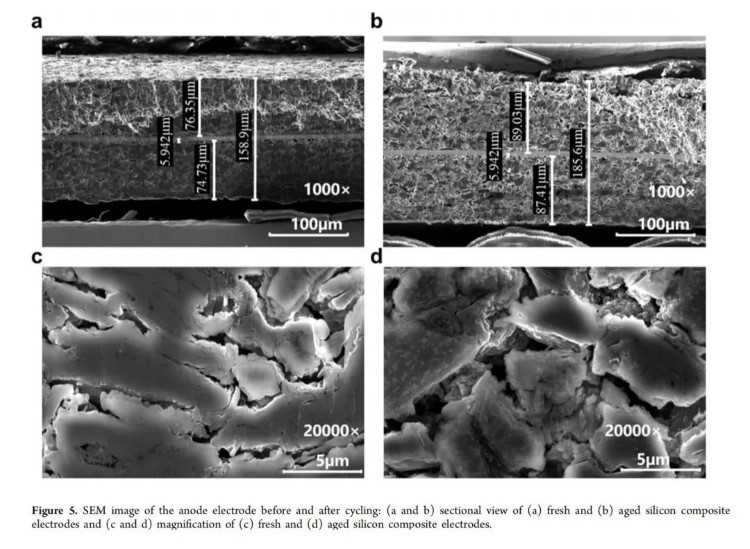

Combining CT and SEM to analyze the thickness difference of the battery core before and after aging, it was found that due to different binding forces, the thickness expansion of different locations of the battery core will also be different, after the battery core ages, the electrolyte dries up, the contact between particles deteriorates, and side reactions increase, etc. These will cause the polarization of the battery core to increase and the capacity to lose.

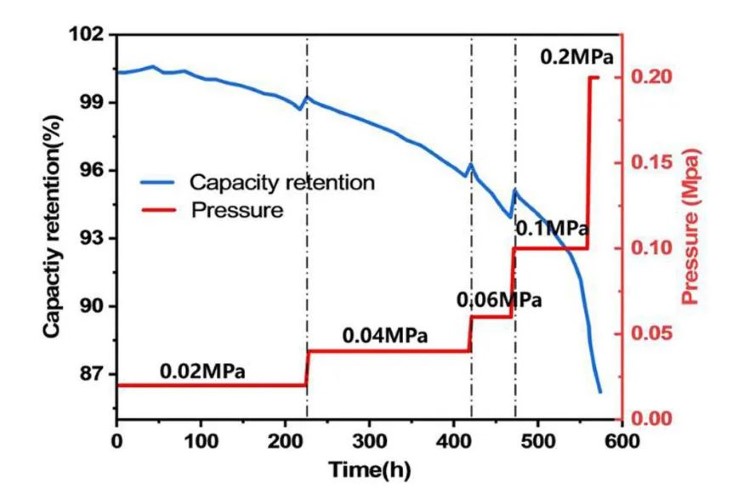

Based on the above analysis, the author developed a way to improve the cycle life of the battery core. During the cycle process of the battery core, the external pressure is continuously increased, which can make the battery core capacity rebound to a certain extent. As the cycle progresses, the electrolyte decomposes to produce serious gas, the particle expansion gap increases, and side reactions increase. Capacity loss can be slowed down by loading increasing pressure, compared with applying a fixed 0.02MPa pressure, the stepped force method increases the capacity retention rate of the battery core from 80% to 85%.

Summarize

By exploring the impact of external pressure on the polarization and cycle performance of silicon anode lithium batteries, it was found that appropriate external pressure can reduce the polarization of the cell during cycling, and applying stepped external pressure during the battery cycle can significantly Improve cycle life. The research results can be used as an effective strategy to increase the capacity of lithium-ion batteries based on silicon-based negative electrodes and guide the process design of battery packs.

Recommended Test Equipment Related to IEST

SWE series in-situ swelling analysis system (IEST): Utilizing a highly stable and reliable automation platform, equipped with a high-precision thickness measurement sensor, it can measure the thickness change amount and change rate of the battery core during the entire charge and discharge process, and can achieve the following functions:

1. Test battery swelling thickness curve under constant pressure condition.

2. Test battery swelling force curve under constant gap condition.

3. Battery compression performance test: stress strain curve – compression modulus.

4. Step-by-step test of battery swelling force.

5. Different temperature controls: -20~80°C.