Development of High-performance Silicon Anode Lithium-ion Batteries Facilitated by A Self-healing Dynamic Hydrogen-bonded Binder

Development of High-performance Silicon Anode Lithium-ion Batteries Facilitated by A Self-healing Dynamic Hydrogen-bonded Binder

Article Abstract

Structural instability and stress accumulation-induced cyclic degradation of silicon (Si) anodes hinder their practical application in next-generation high-energy-density lithium-ion batteries (LIBs). Recently, Master Chen Jiahao and Professor Yang Hui from Nanjing University of Technology polymerized tannic acid (TA) and polyacrylic acid (PAA) binders (recorded as TA-c-PAA) in-situ, developed a cross-linked polymer as a self-healing binder for silicon anodes. As a physical cross-linking agent, branched TA combines with the PAA main chain through rich dynamic hydrogen bonds, giving the cross-linked TA-c-PAA binder unique self-healing properties and strong adhesion to the Si negative electrode. Thanks to the mechanical robustness and strong adhesion, the Si@TA-c-PAA electrode has a high reversible specific capacity (specific capacity of 3250mAh/g at a rate of 0.05C (1C=4000mA/g)), excellent rate capability (specific capacity at 2C rate is 1599mAh/g), and impressive cycle stability (after 450 cycles, the specific capacity at 0.25C rate is still 1742mAh/g). After ex-situ morphology characterization, in-situ expansion analysis and finite element simulation, it was found that the TA-c-PAA binder can disperse the stress and prevent particle crushing during the lithium insertion and delithiation process of the Si anode, and hydrogen bonds between interpenetrating networks can adapt to stress intensity. This work paves a new path for the design of efficient and low-cost binders for next-generation lithium-ion battery silicon anodes.

The related results were published in the internationally renowned journal "J Colloid Interf. Sci." under the title "Dynamic hydrogen bond cross-linking binder with self-healing chemistry enables high-performance silicon anode in lithium-ion batteries".

Three-dimensional flexible self-healing adhesive network cross-linking polyacrylic acid and tannic acid via intermolecular hydrogen bonds

Picture and Text Appreciation

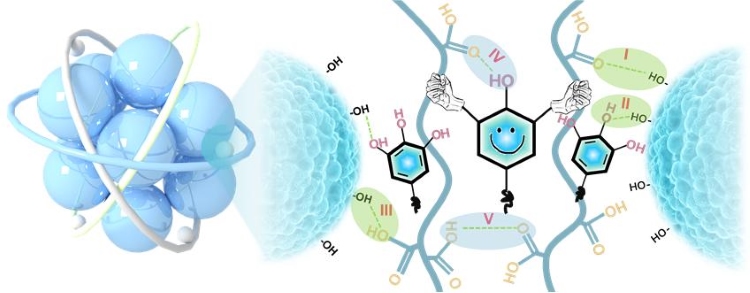

The schematic diagram of the synthesis process and molecular structure of TA-c-PAA polymeric binder is shown in Figure 1. Using acrylic acid as a polymerization monomer and potassium persulfate as an initiator, a three-dimensional cross-linked adhesive is synthesized through free radical reaction. PAA provides the main mechanical support for the main skeleton of the polymer network and has strong adhesion to Si. The author used tannic acid as a physical cross-linking agent and constructed TA-c-PAA to form an interpenetrating cross-linked network through dynamic hydrogen bonding and has self-healing ability and excellent mechanical properties. The method has a feasible preparation process and is easy to be produced on a large scale.

Figure 1.Synthesis process and mechanism study of cross-linked TA-c-PAA adhesive

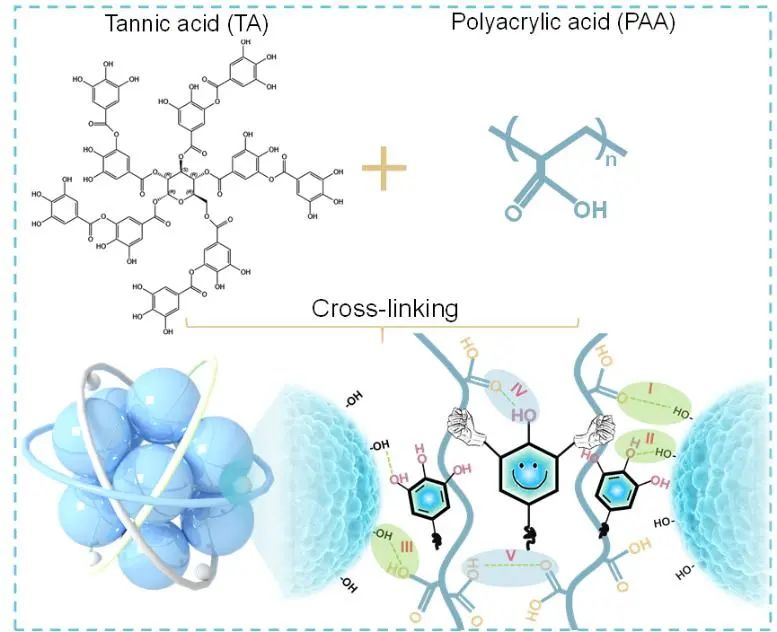

Figure 2(a) shows the FTIR test results of three substances: PAA, TA and TA-c-PAA. The position of C=O moves from 1720 cm-1 of PAA to 1740 cm-1 of TA-c-PAA. It shows that there is (P, C=O...H-O-Ph) bond between TA and PAA. The 1H NMR of TA and TA-c-PAA binders were further analyzed to study the distribution and state of protons within the polymer binder molecule (as shown in Figure 2(b)). Compared with TA and PAA, the proton peak shift of TA-c-PAA is larger, indicating that there are more electronegative elements or chemical groups near the proton, and the reduction in electron cloud density leads to a larger shift, further explaining The formation of intermolecular hydrogen bonds.

The glass transition temperatures (Tg) of PAA and TA-c-PAA were further studied using DSC, and the results are shown in Figure 2(c). The results show that the Tg value of TA-c-PAA is much lower than that of PAA, indicating that weak hydrogen bonds are formed between PAA and TA, which weakens the interaction within the molecular chain and improves the toughness of the polymer binder. To examine the electrochemical stability of the above-mentioned polymer binder, the author further tested cyclic voltammetry (CV) in the range of 0.01 ~ 1.0 V using buckle current, and the results are shown in Figure 2(d). Within the tested voltage range, no obvious redox peak appears for PAA and TA-c-PAA, indicating that both PAA and TA-c-PAA binders are electrochemically inert substances.

Figure 2. (a) FTIR spectra of PAA, TA and TA-c-PAA. (b) 1H NMR spectrum of TA and TA-c-PAA. (c) DSC plots of PAA and TA-c-PAA. (d) CV testing results of copper foil, Cu@TA-c-PAA and Cu@PAA

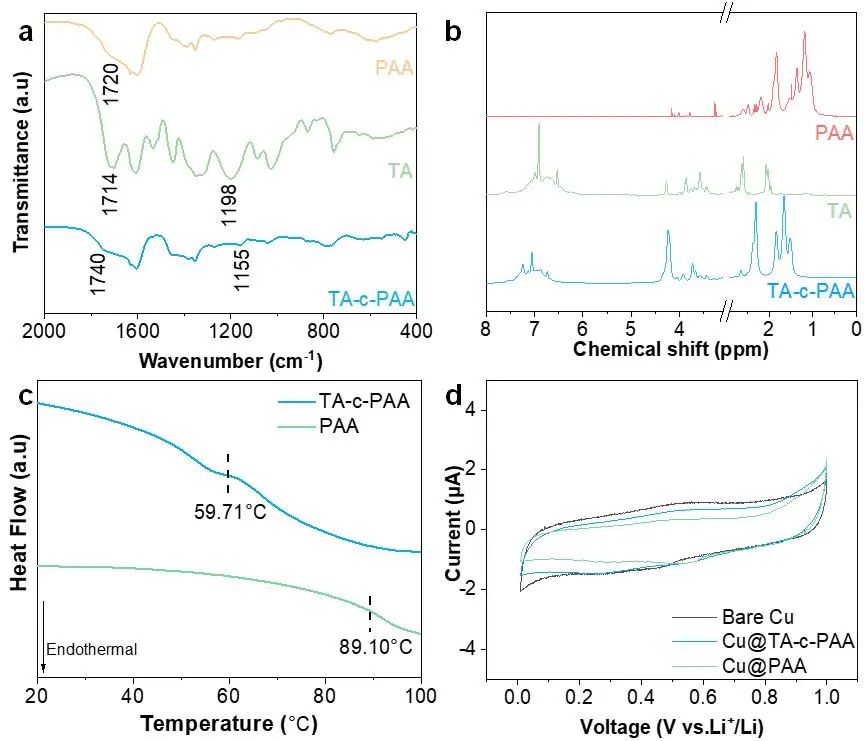

From the stress-strain curve in Figure 3(a), the stress-strain curve of the PAA film is linear, and its tensile strength and elongation at break are 9.97 MPa and 5.02% respectively. In contrast, the TA-c-PAA film has better ductility, with a tensile strength of 5.74 MPa and an elongation of 264.51% (shown in Figure 3d), therefore, the introduction of TA allows the binder to disperse the stress generated during the stretching process. The author then conducted a 180° peeling test on Si@PAA and Si@TA-c-PAA to quantitatively evaluate the adhesion strength between Si electrodes and Cu current collectors, the results are shown in Fig. 3(b) and (e) respectively. The average force values of TA-c-PAA and PAA are 2.06 N and 0.51 N respectively, indicating that the bonding strength of TA-c-PAA binder is stronger after TA is added, this can be attributed to the existence of abundant hydrogen bonds in the TA-c-PAA molecular chain. Therefore, the TA-c-PAA binder greatly enhanced the interface interaction and adhesion between the Si electrode film and the copper foil.

Figure 3. (a) Stress-strain curve of PAA and TA-c-PAA bonded films. (b) 180° stripping curves of Si@PAA and Si@TA-c-PAA electrodes. (c) Cyclic stretching curve of TA-c-PAA adhesive film. (d) Tensile strength and elastic modulus of PAA and TA-c-PAA bonded films. (e) Peeling force and strength of Si@PAA and Si@TA-c-PAA electrodes. (f) Elastic modulus, tensile strength, and maximum force of TA-c-PAA binder during cyclic stretching. (g) Photos of the TA-c-PAA film before and after stretching and shrinkage

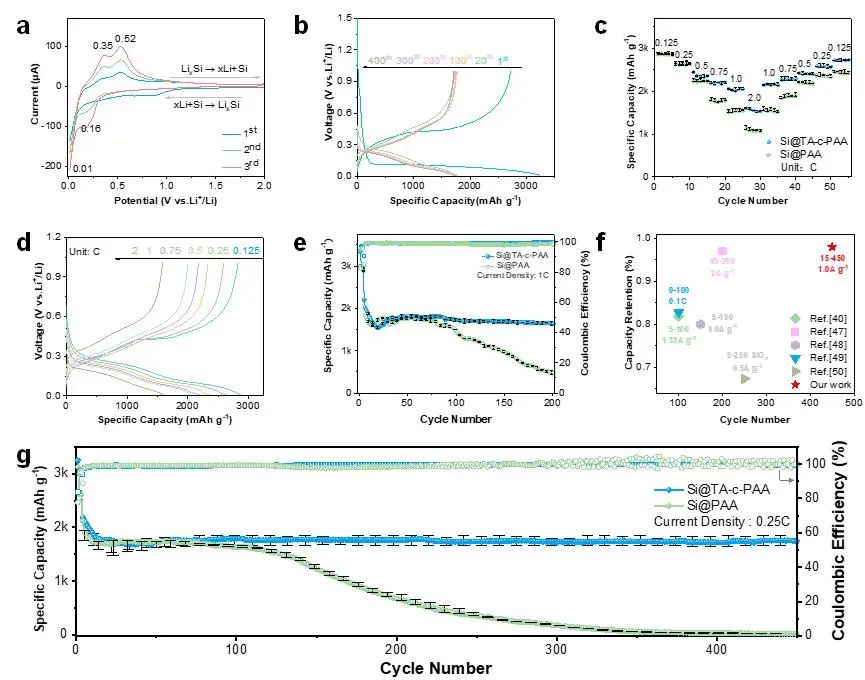

In Figure 4, the author used CR2032 type buckle to conduct research on the electrochemical properties of different binders. As can be seen from Figure 4(a), the CV curve of Si@TA-c-PAA gradually increases in intensity as the number of cycles increases, indicating that its electrochemical kinetics has been significantly improved. At the same time, the discharge/charge curves of the Si@TA-c-PAA electrode after 20, 100, 200, 300 and 400 cycles were in good agreement, indicating good reversibility (as shown in Figure 4(b)). In contrast, the reproducibility of the discharge/charge curve of the Si@PAA electrode is poor (as shown in Figure S8). Furthermore, as shown in Figure 4(c) and (d), the Si@TA-c-PAA electrode exhibits stable rate performance under various current densities, for example, the electrode can achieve a high capacity of 1599 mAh/g at a high current density of 2C. In contrast, the Si@PAA electrode only provides a low capacity of 1118 mAh/g at the same current density.

Figure 4. (a) CV curve of Si@TA-c-PAA electrode at a scanning rate of 0.1 mV s-1. (b) Charge-discharge curve of Si@TA-c-PAA electrode at current density of 0.25C. (c) Rate performance test of Si@TA-c-PAA and Si@PAA electrodes (replicated three times for each binder). (d) Charge-discharge curves at different current densities. (e) Cycling performance of Si@PAA and Si@TA-c-PAA electrodes at 1 C rate (three replicates for each binder). (f) Comparison of cycle performance of silicon-based electrodes under different polymer binders reported in other literature [40,47-50]. (g) Long-term cycling performance of Si@PAA and Si@TA-c-PAA electrodes at a rate of 0.25 C (repeated three times for each binder).

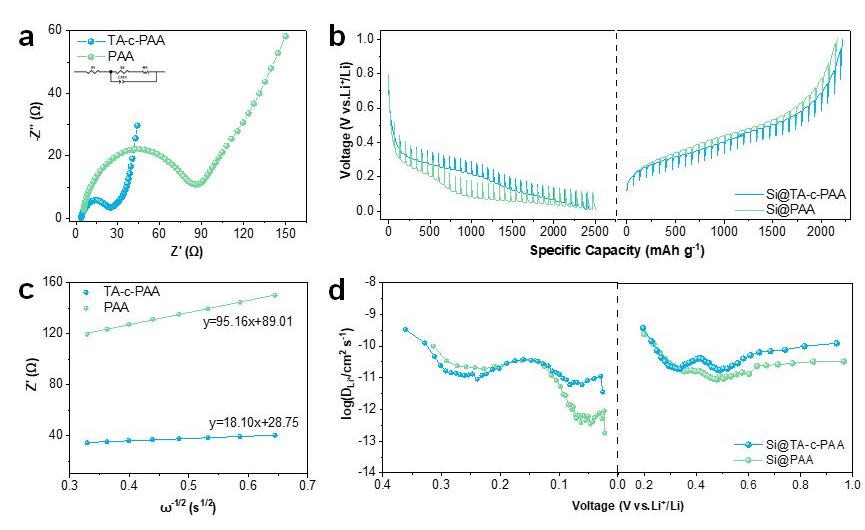

At the same time, the authors used electrochemical impedance spectroscopy (EIS) to further study the electrochemical kinetic properties of Si@PAA and Si@TA-c-PAA electrodes, as shown in Figure 5(a). By calculating the Li+ diffusion coefficient, we can see that the Si@TA-c-PAA electrode has a higher Li+ diffusion coefficient than the Si@PAA electrode (as shown in Figure 5(b)). At the same time, using the constant current intermittent titration technology (GITT), it can also be seen that the Si@TA-c-PAA electrode has a high diffusion coefficient during the charge and discharge process, it shows that the TA-c-PAA binder has a good effect in enhancing Li+ diffusion, which is mainly due to the strong self-repairing ability of the binder ensuring the structural stability of the Si anode.

Figure 5. (a) Nyquist plot of EIS pattern. (b) GITT curves of the Si@TA-c-PAA and Si@PAA electrode. (c) The relationship between Z and ω-1/2 for Si@TA-c-PAA and Si@PAA electrodes in the low frequency region. (d) The diffusion coefficient of lithium ions in Si@TA-c-PAA and Si@PAA electrodes.

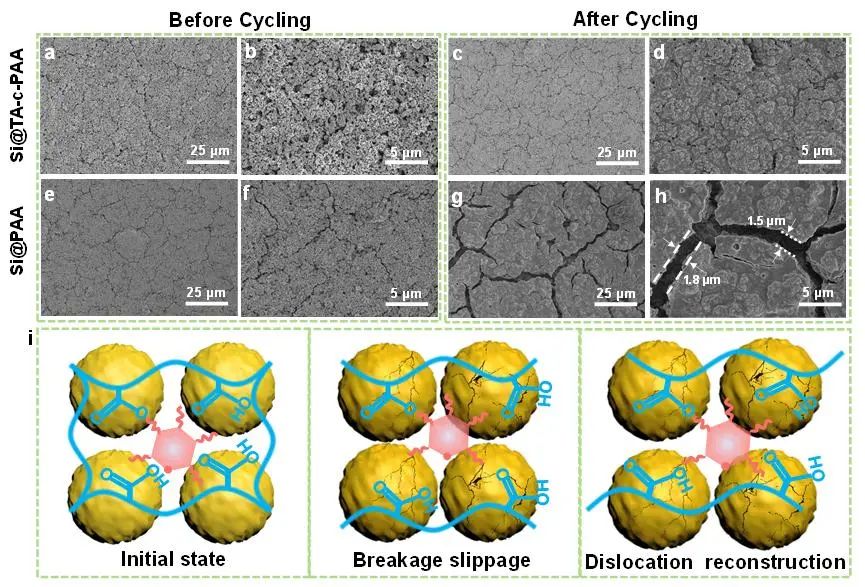

To further investigate the reasons behind the improved performance of the TA-c-PAA binder, the authors used SEM to study the structural evolution of the Si@TA-c-PAA electrode before cycling and after 100 cycles, as shown in Figure 6(a-h) . For fresh electrodes, we observed tiny original cracks in both Si@PAA and Si@TA-c-PAA electrodes, which may be caused by the high surface tension of the electrodes during the rapid drying process. When the electrode was cycled 100 times, large cracks with a width of 1~2 μm appeared on the Si@PAA electrode, resulting in loss of conductive paths and rapid capacity attenuation. In contrast, the Si@TA-c-PAA electrode still remains dense with only a few tiny cracks, indicating its mechanical structure is strong. The microstructural differences between the two electrodes after cycling indicate that the abundant hydrogen bonds in the TA-c-PAA binder give it unique self-healing properties and flexibility, which can quickly dissipate the stress of the Si particles during the charge and discharge process, this prevents the particles of the Si negative electrode from pulverizing.

Figure 6. SEM images of (a)-(d) Si@TA-c-PAA electrode and (e)-(h) Si@PAA electrode before and after cycling for 100 times at 0.25C. (i) The self-healing chemical process of cross-linked TA-c-PAA binder with dynamic hydrogen bonding during charge and discharge processes is proposed.

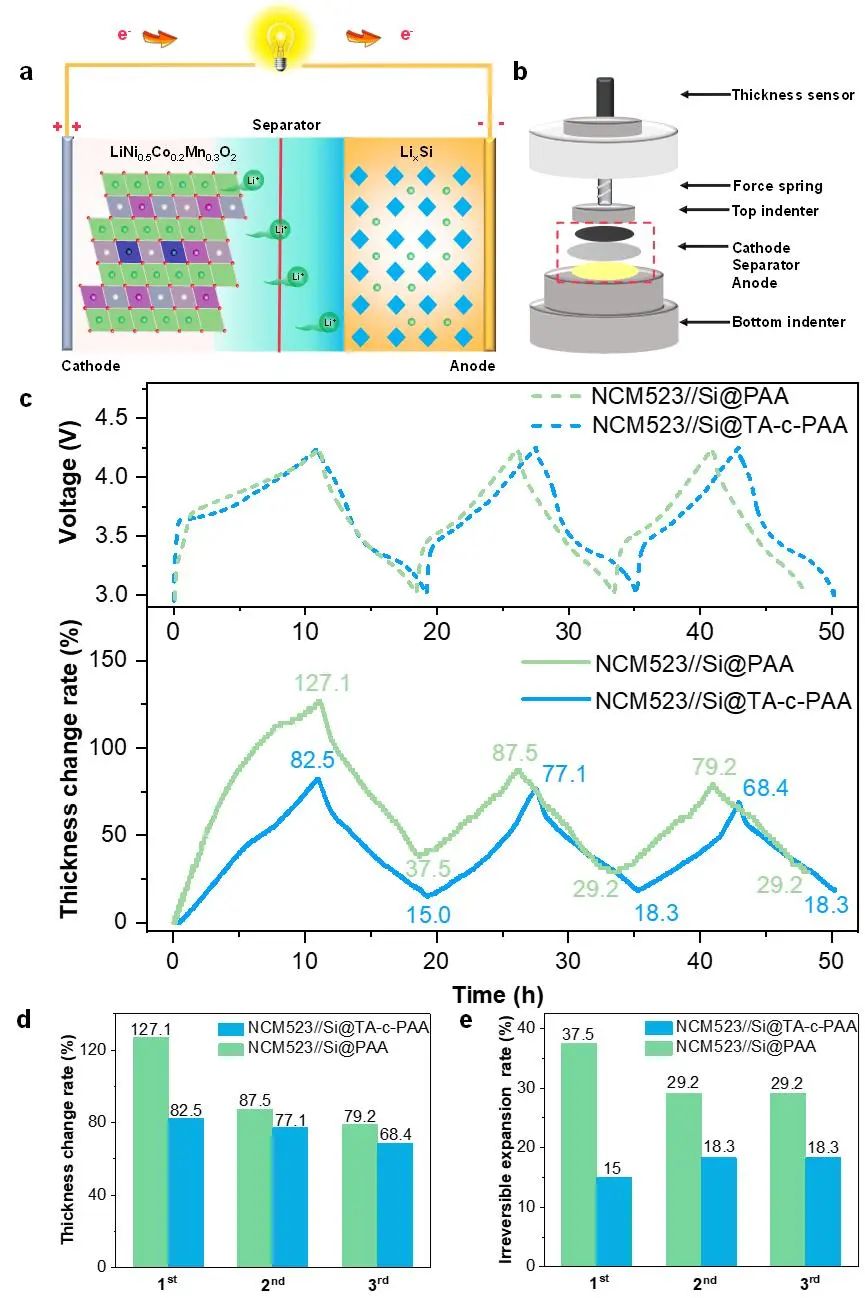

In Figure 7, the authors performed in-situ thickness expansion tests to examine the effects of various binders on suppressing the volume expansion of the silicon anode during charge and discharge cycles. The structure of the in-situ thickness expansion test device is shown in Figure 7(b), in which the force spring and the thickness sensor are assembled in an in-situ expansion analysis system, while the positive electrode, separator and negative electrode are placed between the upper and lower pressure heads. The quality of the NCM523 cathode matches the capacity of the Si@PAA and Si@TA-c-PAA cathodes, and charges and discharges at a 0.1C rate in the voltage range of 3.0-4.25 V, at the same time, the thickness sensor is used to record the thickness changes during charge and discharge in real time. In Figure 7(c), the Si@TA-c-PAA electrode shows a thickness change rate of 82.5% during the lithiation process in the first cycle. In contrast, the thickness change rate of the Si@PAA electrode is 127.1%. During the subsequent delithiation process, the Si@PAA and Si@TA-c-PAA electrodes showed irreversible thickness expansion of 37.5% and 15%, respectively. Overall, the Si@TA-c-PAA electrode exhibited smaller thickness changes and irreversible expansion rates in all cycles, it is shown that dynamic hydrogen bonding promotes the structural stability of silicon-based electrodes (shown in Figure 7(d-e)).

Figure 7.(a) Principle of NCM523//Si full battery. (b) Structural schematic of the in-situ thickness expansion test device. (c) In situ variation curve of thickness of NCM523//Si cell with voltage. (d) Comparison of changes in electrode thickness during cycles. (e) Comparison of the thickness changes of irreversible expansion of electrodes during cycling.

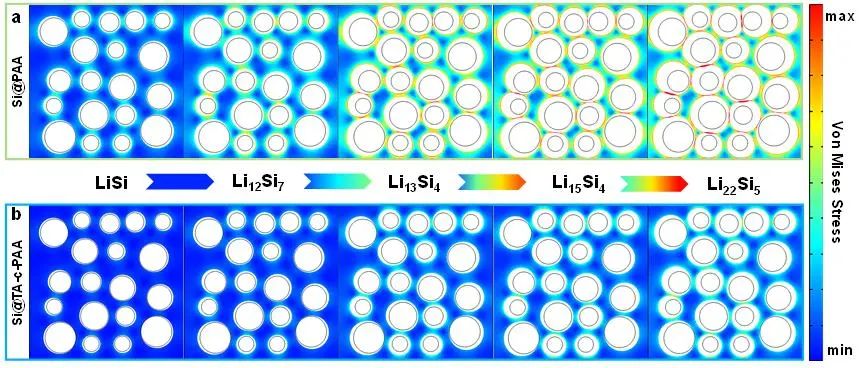

In Figure 8, the author used the COMSOL software to study the relationship between the binder structure and stress dissipation, and conducted finite element simulations of different lithiation states. In the simulation model, the silicon particles are assumed to be independent regular spheres, and they are uniformly distributed in the polymer binder network. Due to the large volume expansion during the lithium intercalation process, there is severe stress concentration on the Si@PAA electrode surface, which may lead to structural failure of the Si anode. When the maximum stress reached 950 MPa, the silicon particles were broken and crushed (as shown in Figure 8(a)). In contrast, the stress distribution of the Si@TA-c-PAA electrode is lower and its mechanical properties are better (as shown in Figure 8(b)). Therefore, the finite element simulation results show that the TA-c-PAA binder plays an important role in the stress dissipation during the periodic lithium insertion/delithiation process of the silicon anode.

Figure 8. Stress evolution of (a) Si@PAA electrode and (b) Si@TA-c-PAA electrode under different lithiation states.

Summary

The authors of this paper designed and prepared TA-c-PAA binder for silicon anode for the first time. Compared with reported or commonly used adhesives (such as alginate and polyacrylic acid), the TA-c-PAA binder has excellent mechanical properties and gives the Si@TA-c-PAA anode excellent electrochemical properties. This is because the optimized TA-c-PAA binder (1:9) has rich dynamic hydrogen bonds and gives it excellent tensile strength, extensibility and elasticity. The corresponding Si@TA-c-PAA electrode also showed enhanced interfacial interaction and effective adhesion between the Si anode and copper foil, and the Si@TA-c-PAA electrode has a high reversible specific capacity (specific capacity at 0.05C rate is 3250 mAh/g) and excellent rate capability (specific capacity at 2C rate is 1599 mAh/g), and impressive cycling stability (the specific capacity at 0.25C rate is still 1742 mAh/g after 450 cycles).

In addition, through ex-situ morphology characterization, in-situ expansion thickness analysis, and finite element simulation, the author found that the TA-c-PAA binder can effectively dissipate the stress concentration of the Si anode during the lithium deintercalation process and prevent particle powdering. The mechanism behind this may be related to the self-healing process of TA-c-PAA adhesive at the microscale. This paper explores the method of polymer binders through physical cross-linking with TA molecules, which may provide a general solution for efficient and economical binder preparation of silicon anodes.

Original Text of the Literature

J.H. Chen, Y.X. Li, X.Y. Wu, H.H. Min, J. Wang, X.M. Liu* and H. Yang*. Dynamic hydrogen bond cross-linking binder with self-healing chemistry enables high-performance silicon anode in lithium-ion batteries. Journal of Colloid And Interface Science 657 (2024) 893-902.