Lithium Battery Innovative Solution & Single Particle Force Properties Test System

1. Background

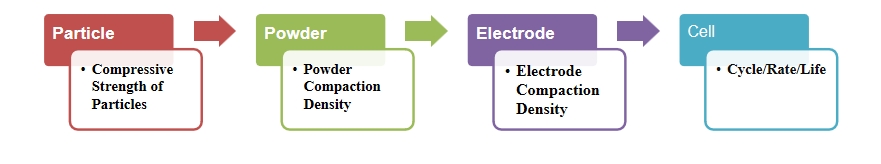

1.2 The relationship between single particle compressive strength and material/electrode/cell performance.

At the microscopic scale, electrodes are composed of nanometer- or micrometer-sized particles. Therefore, the intrinsic particle characteristics of electrode materials play a decisive role in the electrochemical performance of the battery. To obtain electrode materials with ideal electrochemical properties, extensive and in-depth research has been carried out on the crystal structure, morphology, mechanical properties and particle modification methods of granular materials. We can improve the electrochemical properties of particulate materials through composition adjustment, microstructure optimization and surface modification.

In terms of mechanical properties, testing the compressive strength of individual particles of battery materials can be used to evaluate the material's pressure resistance and guide the rolling process. Materials with high mechanical strength will also have better subsequent cyclic stability, as shown in Figure 1.

Figure 1. Correlation between the pressure resistance of lithium battery material particles and the application of different levels of materials

On the one hand, the high compressive strength of the particles indicates that the particles can withstand higher intensity external forces and are less likely to be crushed; corresponding to the pole piece pressing process, it can make the materials or pole pieces have a higher compaction density and can load more positive or negative electrode materials per unit space, which helps to increase the battery capacity density, on the other hand, there is also a certain relationship between the overall compressive strength of the particles and the performance of the final cell. Materials with high compressive strength will improve the overall electrochemical performance of the battery. During the cycle of the cell, as lithium ions are deintercalated and the internal stress of the particles accumulates to a certain extent, cracks or breakage will occur, and the mechanical strength of the particles gradually decreases, thereby shortening the service life of the cell1-3.

For example, research by Parkb1 et al. shows that Mg doping can increase the hardness of NCM622 particles, thereby improving the cycle performance of the NCM622 cathode. Therefore, the authors believe that particle hardness is a key factor that directly affects the long-term cycle stability of the NCM622 cathode. The mechanical strength (pressure resistance) of the battery's positive and negative electrode materials affects the electrochemical performance of the positive and negative electrode materials. This correlation provides new ideas for the study of positive and negative electrode materials.

In addition, we often need to optimize electrode manufacturing process parameters through simulation, such as the rolling process, or predict the evolution of the microstructure during battery charging and discharging. When performing refined structural simulation of electrodes, the model requires detailed performance parameters of the granular material, including mechanical property parameters, such as elastic model and fracture strength. Single-particle mechanical properties can quickly and accurately obtain these parameters, thereby helping to build more accurate models.Therefore, the testing of single particle mechanical properties of lithium battery materials can not only provide key material performance parameters, but also help to deeply understand the relationship between material properties and battery performance, thereby guiding the battery design and manufacturing process and improving battery performance and life.

1.2 Limitations of Existing Characterization Methods

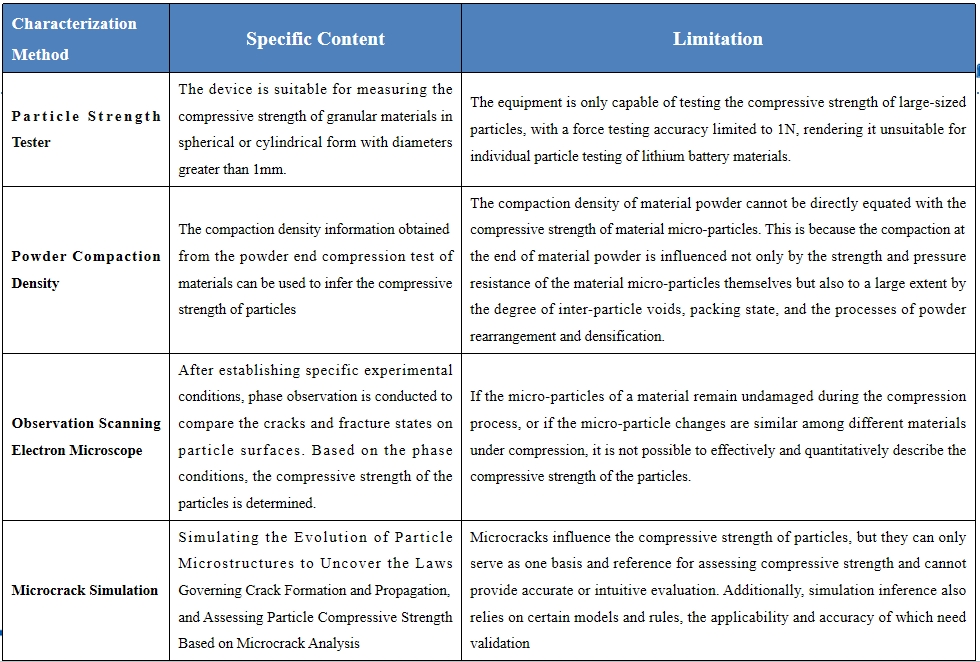

Some existing methods for characterization of surface micromechanical properties of materials, such as force curve testing with atomic force microscope, hardness testing with nanoindentation instrument, the test mainly focuses on the mechanical properties of the film or coating substrate, which is not applicable to micron-level battery material particles and is difficult to reflect the pressure resistance of the particles themselves. Some other characterization methods, as shown in Table 1, also have certain limitations and cannot describe the compressive properties of particles intuitively and quantitatively.

Table 1. Lithium battery particle strength characterization methods and their limitations

2. Lithium Battery Single Particle Mechanical Properties Testing System

2.1 Basic Product Information

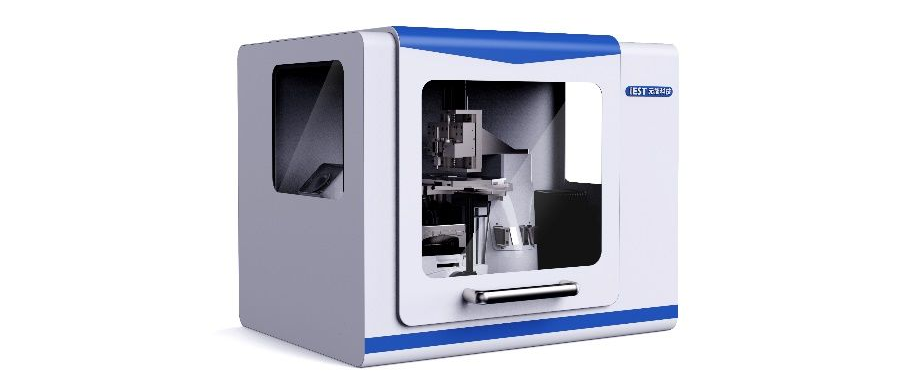

Figure 2. IEST single particle mechanical property testing system SPFT2000

Based on the importance of the single particle mechanical properties of lithium battery materials and the urgent need for single particle characterization by many lithium battery industry R&D personnel, IEST launched the single particle force properties test system SPFT (Single Particle Force Properties Tester), as shown in Figure 2.

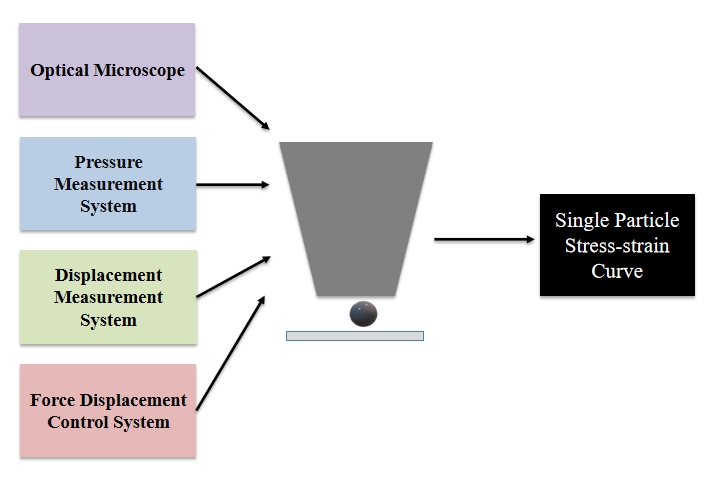

Figure 3. Single particle mechanical properties testing system SPFT functional module

SPFT is composed of an optical microscope, a pressure measurement system, a displacement measurement system, and a force displacement control system. Through high-precision displacement and pressure control, the stress-strain curve after the indenter is loaded onto a single particle can be collected and the particle crushing force can be analyzed from the mutation point of the curve. During the test process, you can use an optical microscope to observe the shape of the particles before and after pressing, the size information of the test particles, etc.

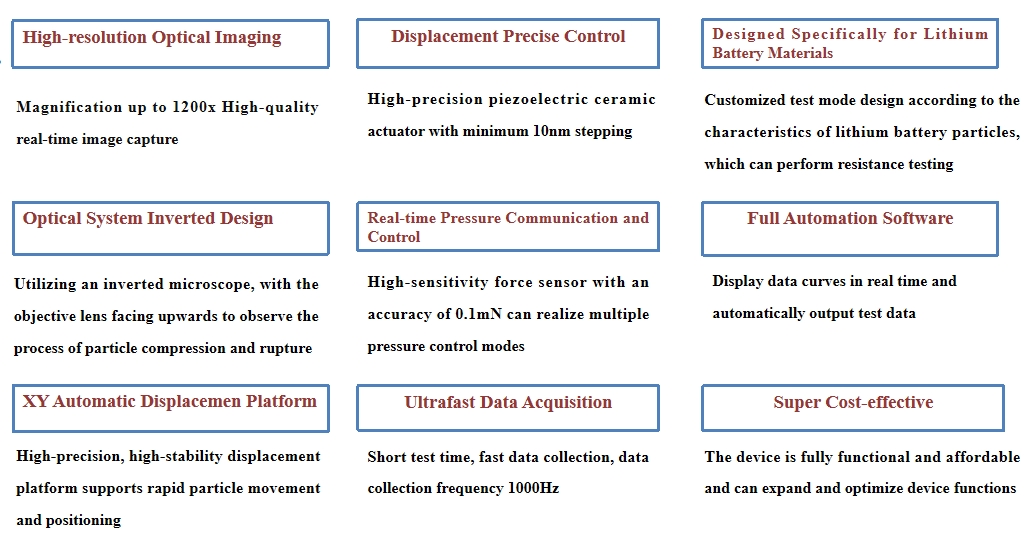

2.2 Product Features

SPFT is a single-particle mechanical property testing equipment specially developed for lithium battery materials. It can design customized test modes based on the characteristics of lithium battery particles. It has good specificity, complete basic functions, and high-cost performance. The structural design is bold and innovative, using a bottom optical system so that the relative position of the indenter and particles can be observed during particle testing, the operation is more direct and simpler for personnel, which reduces the risk of pressure deviation, particles being crushed away, or multiple particles being crushed. The collapse state of particles before and after crushing can also be observed from the bottom. The specific features of SPFT are shown in Figure 4.

Figure 4. Functional features of single particle mechanical property testing system

2.3 Test Methods

(1) Refer to GB/T 43091-2023 powder compressive strength test method 4.

(2) The sample testing steps include: sample preparation, positioning, mode selection, and test start. The entire process only takes a few minutes.

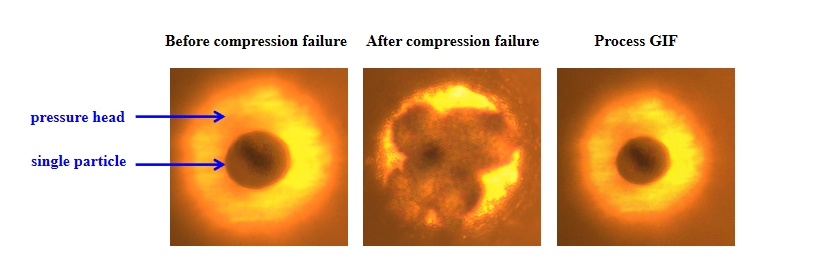

(3) Test process and pictures before and after the particles are crushed, as shown in Figure 5.

Figure 5. Single particle test process morphology

3. Application Cases

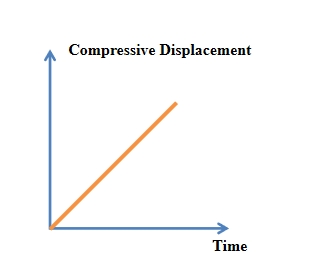

SPFT provides a variety of test modes, and testers can choose the corresponding test mode according to the sample type or different testing requirements. The following case adopts the test mode of controlling displacement to test stress (as shown in Figure 6), that is, pressing down the particles at a constant displacement rate to test the changes in particle stress during the compression of the particles.

Figure 6. Test pattern to control displacement

The displacement rate unit is μm/s, usually in the range (0.1~0.5μm/s), and the displacement stability is controlled within ±0.01μm. When the indenter presses down to the upper limit of the displacement stroke or the set upper limit of the pressure, the software automatically stops the test and saves the data.

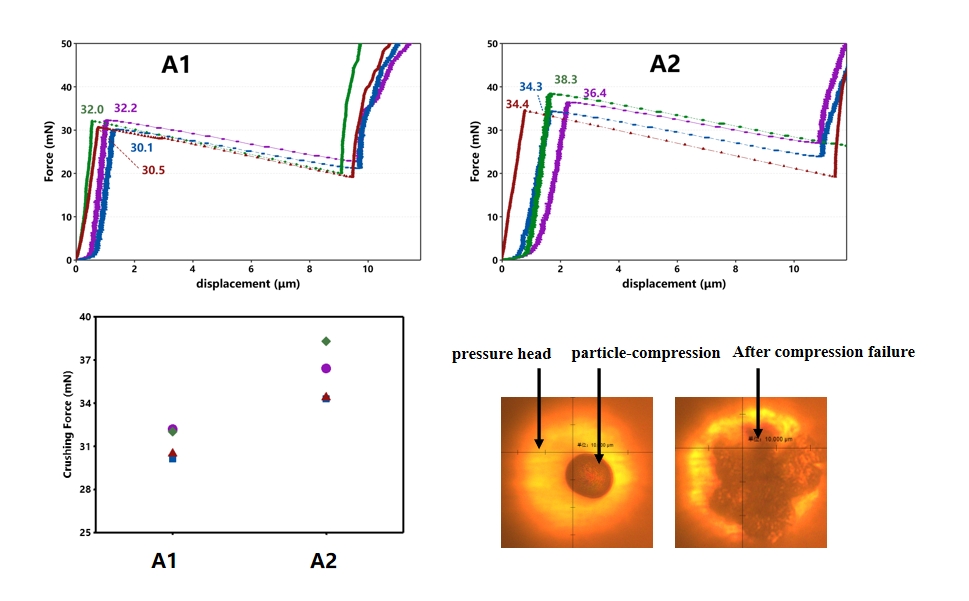

3.1 Ternary Particles A1 and A2

The two ternary materials A1 and A2 are sintered from the same precursor, but the sintering process is different. The particle size D50 is both 18 μm. We used SPFT2000 to test different particles of two materials. The results are shown in Figure 7. The average crushing force of A1 is 31.2mN and that of A2 is 35.8mN. Moreover, the change in displacement of A2 when it is crushed (the abscissa corresponding to the crushing point) is slightly larger than that of A1, which means that A2 is crushed when it is pressed deeper, and the average pressure is 0.8 μm. The above results show that the compression resistance of A2 is better than A1, and changing the sintering process can improve the material hardness to a certain extent. The characterization method of single particle mechanical properties can provide guidance for the sintering process of materials.

Figure 7. Comparison of the stress-strain curves and crushing forces of A1 and A2

3.2 Ternary Particles B1 and B2

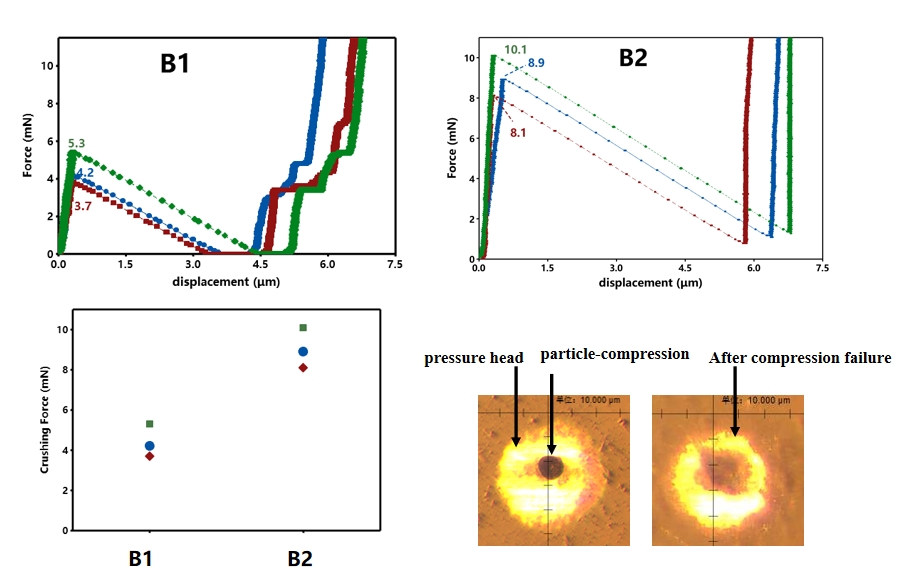

Two ternary materials, B1 and B2, are sintered from different precursors, and the particle size D50 is both 9.5 μm. We used SPFT2000 to test the single-particle mechanical properties of the two materials. The results are shown in Figure 8. The average crushing force of B1 is 4.4mN, and the average crushing force of B2 is 9mN. The crushing force of B2 is greater than B1. Judging from the curve, after B1 is crushed, the stress drops to zero, while the force of B2 drops to 2mN, and after B1 particles are crushed,as the indenter continues to press down, there are multiple stages of platforms on the force-displacement curve. This shows that the B1 particles may have a faster process of structural fragmentation, and the material elasticity is smaller than that of B2. When the indenter is pressed down after the primary fragmentation, there may be partially fragmented particles that are crushed twice.

After these two materials were assembled into half-cells according to the same process, they were cycled for 30 cycles at 45°C. The capacity retention rate of the battery corresponding to B1 was 84%, while the capacity retention rate of B2 was 94%, the cycle stability of B2 was better. This is also related to B2's higher single-particle hardness at the material level.

Figure 8. Comparison of B1 and B2 stress-strain curves and crushing force

4. More Information on Single Particle Mechanical Testing System SPFT

4.1 Test Object

In addition to the ternary cathode materials for lithium batteries shown in the above cases, other positive and negative electrode materials for lithium batteries, including cathode ternary single crystals, lithium-rich materials, negative electrode graphite, silicon-based, solid electrolytes, etc., can be tested. It should be noted that due to the complex external environmental conditions during particle formation, the internal structures of some material particles have great differences. Therefore, even particles with similar shapes and sizes can exhibit significant variability in their compressive strength.

4.2 Test Particle Size

Single particle size: 5~50um, spherical or cylindrical particles have better testing results.

4.3 Application Scenario

Material R&D departments, quality control departments of material companies, battery cell companies, and material development research groups in universities can be used for material design and optimization verification.

In short, the compressive strength (crush strength) test of single particles of lithium battery materials can be used to evaluate the compressive resistance of the material and can help guide R&D personnel in material optimization, process design, and battery cell development.

5. References

1.Janghyuk Moona, Jae Yup Jungb, Trung Dinh Hoanga, Dong Young Rheeb, Hyo Bin Leeb, Min-Sik Parkb,*, Ji-Sang Yuc,** The correlation between particle hardness and cycle performance of layered cathode materials for lithium-ion batteries,Journal of Power Sources 486(2021)229359.

2.Sergiy Antonyuka, Jürgen Tomasa, Stefan Heinrichb, Lothar Mörlb, Breakage behaviour of spherical granulates by compression, Chemical Engineering Science 60 (2005) 4031 – 4044.

3. Zhang Yusheng, You Xiaoming, He Qing. Research on the crushing strength of 8YSZ agglomerated powder and its influence on PS-PVD deposition behavior [J]. Thermal Spray Technology, 2022, 14(3): 46-57.

4.GB/T 43091-2023 "Powder Compressive Strength Test Method"