Take Enhancing Cycling Stability in Li-rich Mn-based Cathode Materials by Solid-liquid-gas Integrated Interface Engineering

Literature Appreciation: Take Enhancing Cycling Stability in Li-rich Mn-based Cathode Materials by Solid-liquid-gas Integrated Interface Engineering

Author Information and Article Summary

In 2022, a team led by Professor Peng Dongliang and researcher Xie Qingshui of Xiamen University developed a solid liquid gas integrated surface modification method, introducing CEI pre structure layer and defect heterostructure on the surface of lithium rich manganese based cathode material (LRM), which significantly improved the cycle stability of the material. This work has opened up a new idea to regulate the stability of LRM surface and interface, which plays an important role in the development of high energy density lithium ion batteries. Professor Peng Dongliang and special researcher Xie Qingshui from the School of Materials, Xiamen University are the corresponding authors of this article, and Guo Weibin, a doctoral student from the School of Materials, Xiamen University, is the first author of this article.

Sample Preparation and Testing

1.Preparation of initial lithium rich manganese based cathode material PLRM;

2.Preparation of lithium rich manganese cathode material DLRM assisted by dimethyl oxalate (DMO);

3.Test Items: Composition analysis, crystal structure analysis, morphology analysis, electrochemical performance analysis, DFT calculation, electrode resistance analysis (BER1300-IEST), in-situ gas production test of soft packed electric core (GVM2200-IEST), etc.

Result Analysis

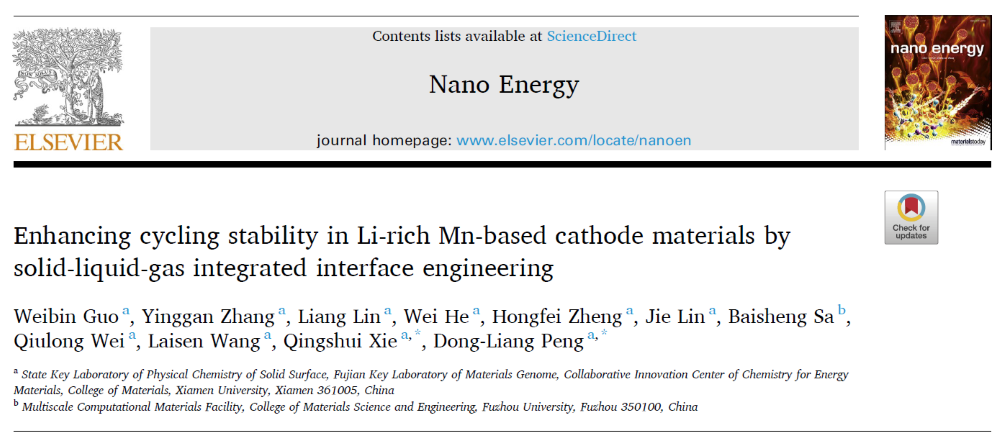

As shown in Figure 1, the author found that after DMO assisted surface/interface modification of LRM, uniform CEI pre structure layer and defect heterostructure can be formed on the surface of LRM secondary particles and the surface/interface of internal primary particles. The CEI pre structure layer contains C2O4H2 group, and the defective heterostructures include lithium defects, oxygen vacancies, spinel/layered heterostructures, TM vacancies, stacking faults, etc.

Figure 1.Schematic diagram of surface modification method for solid liquid gas integration and morphology and microstructure of modified LRM

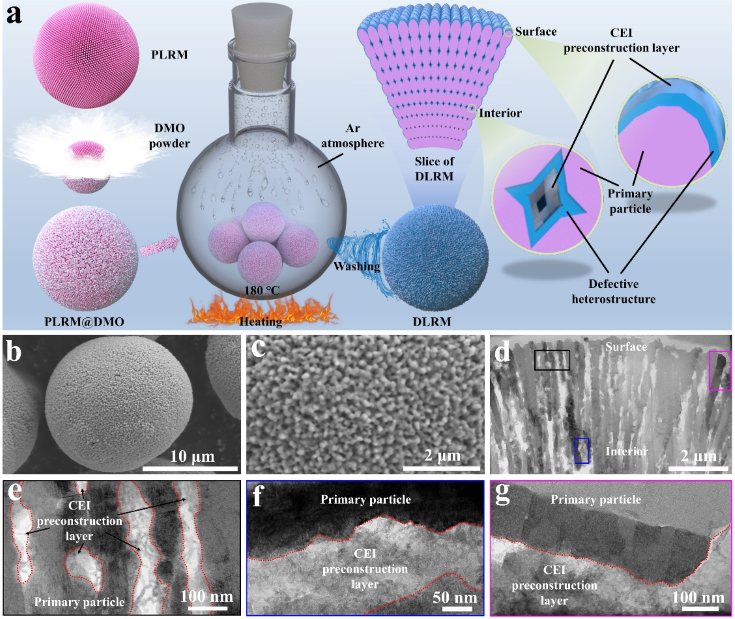

By comparing the electronic resistance of the materials at the electrode slice level before and after modification (Fig. 2), it can be found that the electrode slice resistance of DLRM is less than PLRM, and the ion transfer resistance Rct of the initial DLRM is also less than PLRM; After 500 cycles at 1C, the Rct growth of DLRM was also significantly smaller than that of PLRM. Analyzing the reasons, the reduction of Rct is mainly attributed to the presence of defective heterostructures on the surface, such as lithium vacancy, oxygen vacancy and TM vacancy, which will reduce the diffusion barrier of Li+, while the spinel/layered heterostructures can improve the electronic conductivity and provide a fast three-dimensional diffusion channel for Li+, so DLRM has better magnification capability.

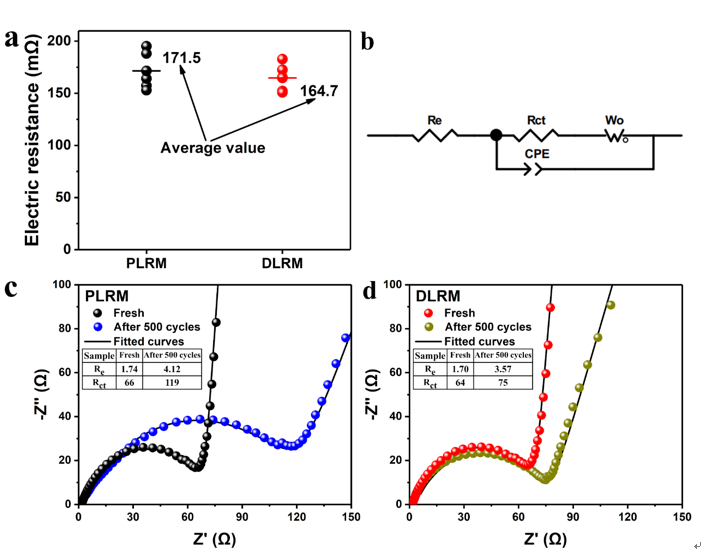

By analyzing the morphology of the sample after circulation, there is a thick, rough and cracked CEI layer on the surface of PLRM particles after circulation, while the CEI layer on the surface of DLRM is obviously thin and uniform, which indicates that the constructed CEI pre structure layer and defect heterostructure can effectively slow down the corrosion of electrolyte on the material surface and avoid some side reactions of electrolyte. In order to confirm the degree of side reaction of the two materials, the in situ volume change test was conducted on the single-layer soft package battery assembled by the two materials (Fig. 3). The volume change during the first cycle charge discharge process is mainly caused by aerobic precipitation and interface side reaction. Comparing the volume change of the two types of electric cores, it is obvious that the volume expansion per unit mass of DLRM is less than that of PLRM, which also shows that DLRM has better surface and structural stability.

Figure 2. LRM electrode resistance and EIS impedance test results before and after modification

Figure 3. In-situ Volume Test Results of Soft Packed Electric Core of LRM before and after Modification

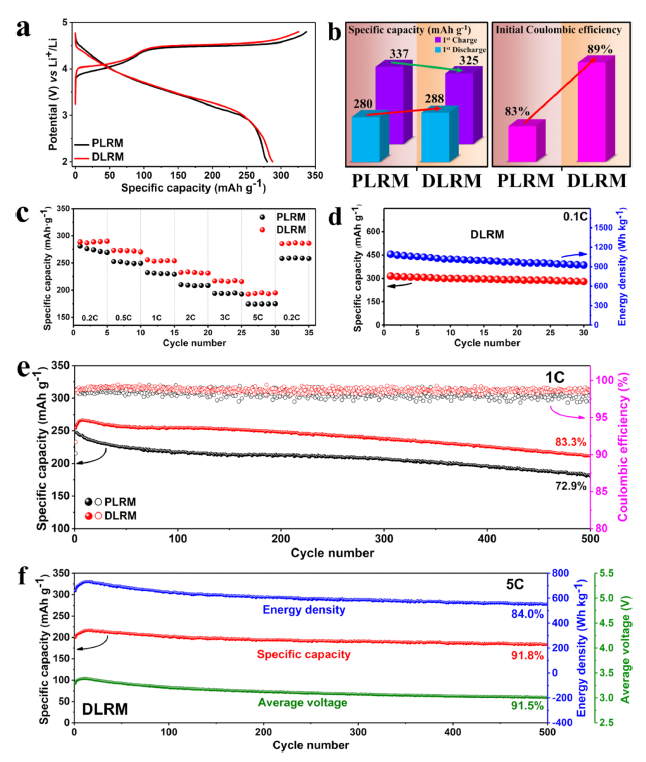

The electrochemical performance test results show (Fig. 4) that compared with PLRM, the charge specific capacity of the modified DLRM decreases while the discharge specific capacity increases. This is mainly because the modified DLRM removes the residual lithium source on the surface of the material and forms lithium defects and spinel structures on the surface, which effectively improves the surface stability of the material, thus obtaining a high first coulomb efficiency. In addition, DLRM shows better magnification performance and cycle stability. After 500 cycles at 1C, the capacity retention rate of DLRM can still reach 83.3%, which is significantly higher than 72.9% of PLRM.

Figure 4. Electrical performance test results of LRM before and after improvement

Summary

To sum up, DMO assisted solid liquid gas integration surface modification method was used to introduce CEI pre structured layer and defect heterostructure on the surface of lithium rich manganese based cathode material (LRM), effectively improving the surface and structure stability of LRM, thus improving its comprehensive electrochemical performance. This work provides a simple method to improve the cycle stability of layered cathode materials, which is expected to be applied to industrial production.

Original Documents

Weibin Guo, Yinggan Zhang, Liang Lin, Wei He, Hongfei Zheng, Jie Lin, Baisheng Sa, Qiulong Wei, Laisen Wang, Qingshui Xie and Dong-Liang Peng. Enhancing cycling stability in Li-rich Mn-based cathode materials by solid-liquid-gas integrated interface engineering.Nano Energy 97 (2022) 107201. https://doi.org/10.1016/j.nanoen.2022.107201

IEST Related Test Equipment Recommendation

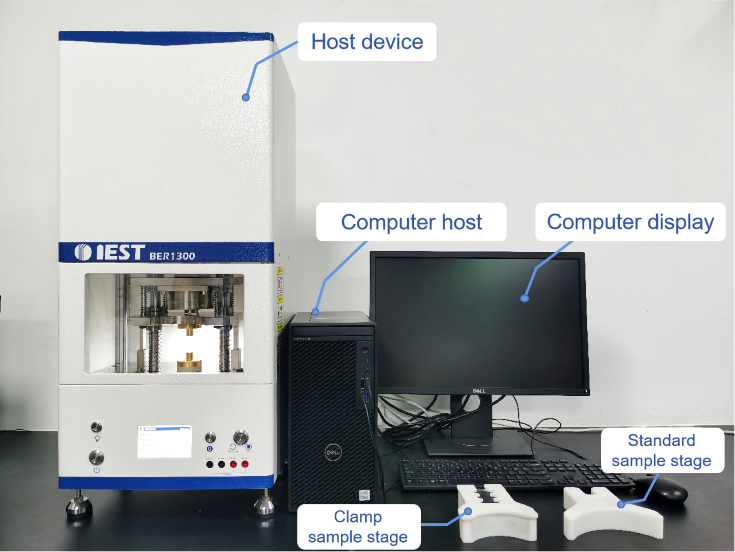

Equipment I

Electrode Sheet Resistance Meter: Model BER1300 (IEST), which adopts double plane controllable voltage disc electrode resistance method, has the following characteristics:

1. Separate voltage and current lines, eliminate the influence of inductance on voltage measurement, and improve the detection accuracy;

2. The disk electrode with a diameter of 14 mm ensures a relatively large contact area with the sample and reduces the test error;

3. Directly measure the longitudinal penetration resistance of the real electrode piece, that is, the sum of coating resistance, coating and collector fluid contact resistance, and collector fluid resistance;

4. It can monitor the changes of electrode sheet resistance, electrode sheet thickness and electrode sheet pressure density with pressure in real time;

5. The applied pressure can be accurately controlled to ensure the consistency of test data;

Equipment 2

In-situ Gas Production Volume Monitor: model GVM2200 (IEST), with the following features:

1.Electromechanical concentric testing system: long-term in-situ online monitoring with high resolution μ L;

2.Realize different temperature test environment: 20~85 ℃;

3.Special test software: collect and display the data of mechanical test system in real time, and automatically draw the volume change curve and electrical performance curve.