In-situ Swelling Characterization Method for Cylindrical Batteries

During the charging and discharging process of lithium-ion batteries, phenomena such as electrode material expansion, SEI growth, thermal expansion, and gas production may cause battery expansion, thereby causing volume changes. Battery expansion is considered one of the key indicators to evaluate battery capacity and structural degradation and is also an early warning of serious safety events such as combustion and explosion during battery abuse. There are mature methods to characterize the expansion behavior of prismatic and pouch batteries, but there is no mature and stable expansion characterization method for cylindrical batteries due to the particularity of their structure. At present, there are some methods to characterize the expansion of cylindrical batteries, such as vernier calipers, three-dimensional coordinate testers, pressure films, strain gauges, image analysis methods (CT tomography, neutron imaging, X-ray, ultrasound, etc.) and other testing methods, however, these methods have problems such as low accuracy and inability to test in situ, and cannot accurately and completely describe the expansion behavior of cylindrical batteries.

In view of the shortcomings of the above test methods, IEST developed the CCS1300-4 cylindrical battery in-situ expansion test system based on optical battery imaging technology, which is used to characterize the in-situ expansion of cylindrical batteries. This method can test the volume changes of cylindrical batteries in situ during charging and discharging, reconstruct the surface morphology of the battery in real time and calculate the expansion amount, and the optical detection accuracy can reach ±1μm. This paper uses the CCS1300-4 cylindrical battery in-situ expansion test system to test two 21700 cylindrical batteries with different negative electrode silicon contents, characterize the expansion behavior of the two during formation and charge and discharge processes, analyze the impact of different silicon contents on battery expansion behavior, and guide the application of silicon anodes and cylindrical battery design.

1.Experimental Equipment and Testing Methods

1.1 Experimental Equipment

This article uses the CCS1300-4 cylindrical battery in-situ expansion test system to characterize the expansion of 21700 cylindrical batteries. The equipment includes a 4-channel test fixture and special test software. When used with a charge and discharge instrument, it can perform in-situ expansion tests on 4 cylindrical batteries at the same time.

Figure 1. CCS1300-4 cylindrical battery in-situ expansion test system

1.2 Testing Principle

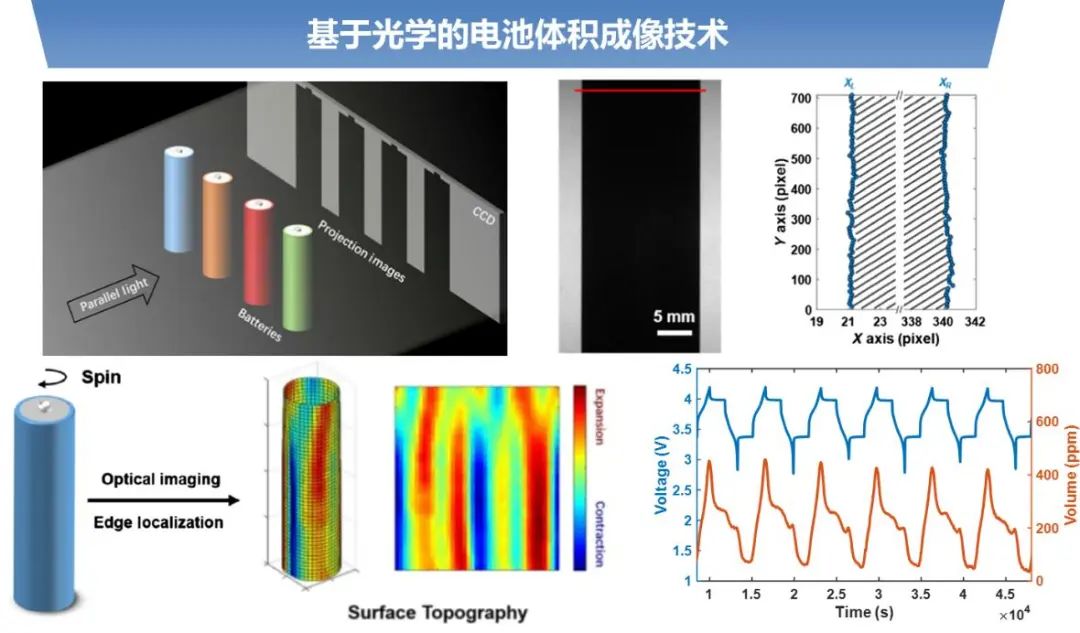

As shown in Figure 2, optical-based battery volume imaging technology is used to perform real-time three-dimensional reconstruction of the surface morphology of the battery during the charge and discharge process and calculate the volume and volume change during the charge and discharge process.

Optical-based Battery Volume Imaging Technology

Figure 2. Schematic diagram of the principle of optical method for testing cylindrical battery expansion.

1.3 Test Method: Remove the outer plastic film of the 21700 cylindrical battery, install it on the equipment fixture, open the software, and set the charge and discharge channel, sampling angle, alarm temperature upper limit, and alarm volume upper limit. Start the program, the battery is rotated and volume tested, and the software automatically synchronizes the charge and discharge data with the volume test data.

2.Cylindrical Battery Swelling Test

Two 21700 5Ah cylindrical batteries with different negative electrode silicon contents were selected to test the volume expansion during the formation and charge and discharge processes of the two batteries.

Table 1. Two Types of 21700 Cylindrical Battery Information

Battery Serial | Battery Info | Design Differences |

S1 | 21700 5Ah battery,before forming | 15% Silicone |

S2 | 21700 5A battery,before forming | 10% Silicone |

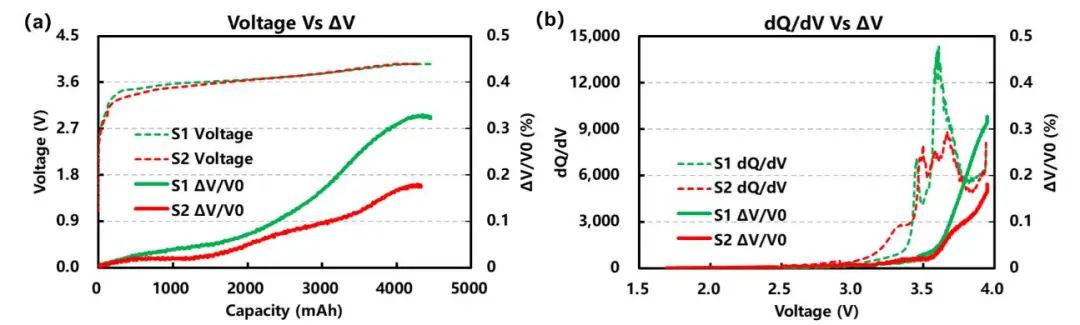

As shown in Figure 3, as the silicon content in the negative electrode increases, the volume expansion increases significantly during the formation process, and the peak value corresponding to lithium insertion on the differential capacity curve will be higher, indicating that the silicon content has a greater impact on the volume expansion of cylindrical batteries. During the formation process, the silicon-carbon negative electrode is the main cause of battery volume expansion. After graphite is embedded with lithium, the volume expands by about 10%, and the volume of silicon-oxygen expands by about 120%. The overall volume expansion of the negative electrode is the sum of the expansion volumes of graphite and silicon-oxygen. Of course, the pores and binders of the electrode pieces can accommodate a certain expansion volume. Therefore, the higher the silicon-oxygen content, the cell exhibits greater volume expansion.

Figure 3. S1 and S2 form an expansion curve.

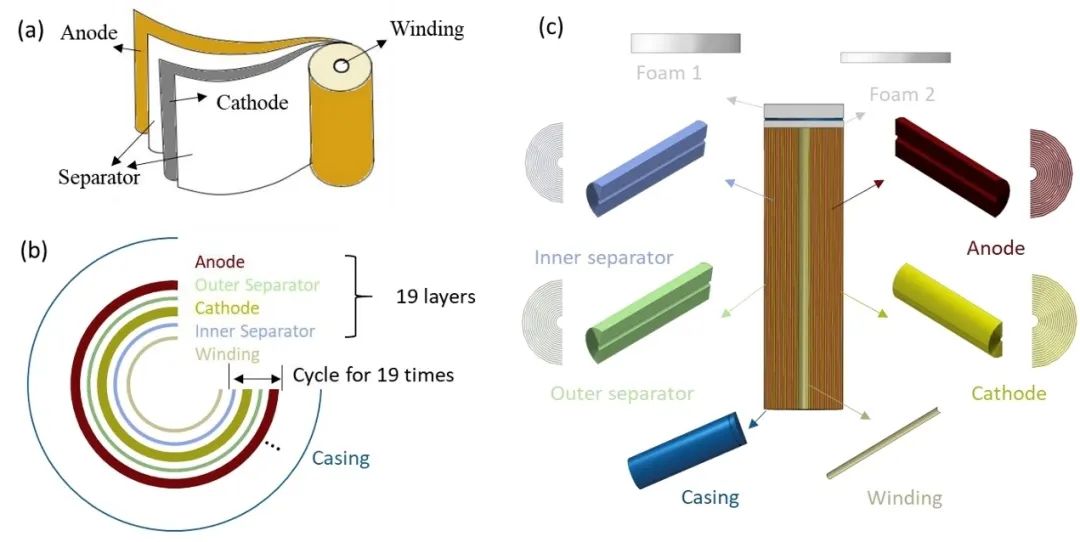

The two batteries were tested for charge and discharge, and the surface morphology of the battery during the charge and discharge process was reconstructed in real time to obtain a dynamic change diagram of the battery surface morphology during the entire charge and discharge process. As shown in Figure 4, the battery volume expands significantly during the charge and discharge process, and the battery itself has large uneven volume expansion. Comparing S1 and S2, it is found that the expansion unevenness of S2 is higher than that of S1. This difference in unevenness should be related to the internal bare cell structure of the two batteries. Cylindrical batteries are assembled from a core with positive and negative electrode sheets and separators wound in a cylindrical manner, tabs welded to the electrodes, insulating pads, top covers and casings. The tabs on the electrodes will cause roll The non-uniformity of the core thickness, the structure and state of each component, etc. will cause the non-uniformity of the overall volume change of the battery. In addition, the pole pieces will also wrinkle during the expansion and contraction process, causing irreversible volume expansion. The volume expansion caused by these pole piece wrinkles will also cause uneven battery volume expansion.

Figure 4. Dynamic changes in surface morphology during charging and discharging of S1 and S2.

Figure 5. Schematic diagram of various parts of the cylindrical battery

3.Summary

This article uses the CCS1300-4 cylindrical battery in-situ expansion test system to test the expansion behavior of two 21700 cylindrical batteries with different silicon content in the negative electrode during the formation and charge and discharge processes. The test found that the silicon oxygen content has a very significant impact on the volume expansion of the cylindrical battery, and the battery itself has large unevenness in the volume expansion. By analyzing volume expansion data and surface morphology dynamic changes, data support can be provided for the application of silicon anode materials and cylindrical battery structure design, and can assist lithium-ion battery research and development and quality control.

References

1.Wenxuan Jiang, Haoran Li, Sicong Wang, Sa Wang and Wei Wang, Dynamic Volumography of Cylindrical Li-Ion Battery Cells by Watching Its Breath During Cycling, https://doi.org/10.31635/ccschem.023.202202680.

2.Lubing Wang, Sha Yin, Jun Xu,A detailed computational model for cylindrical lithium-ion batteries under mechanical loading: From cell deformation to short-circuit onset,Journal of Power Sources,2019,413,284-292