A Semi-intercalation Reaction to Enhance the Redox Kinetics of All-solid-state Lithium-sulfur Batteries

A Semi-intercalation Reaction to Enhance the Redox Kinetics of All-solid-state Lithium-sulfur Batteries

Author Information and Article Abstract

In 2022, Dr. Li Chuang of Tsinghua Shenzhen Research Institute developed a solid-state lithium-sulfurized polyacrylonitrile (Li-SPAN) battery with a salt-coated polymer electrolyte. In this structure, sulfur is fixed in the polyacrylonitrile substrate during cycling, the formation of Li2S is prevented, so that its performance exhibits faster redox kinetics and smaller volume changes than conventional solid-state lithium-sulfur battery systems. This article is the first report to improve the redox kinetics of solid-state Li-SPAN batteries by changing the strength of C-S bonds instead of using catalysts, which opens up new opportunities for the design of higher-performance solid-state lithium-sulfur batteries in the future.

Experimental Protocol

1. Material Preparation: 1PVHF1FSI solid electrolyte, solid SPAN positive electrode.

2.Electrochemical Test: The ionic conductivity of the electrolyte was tested by EIS, and the 2032-type Li-SPAN button battery and soft-packed battery cells were prepared, and the volume swelling of SPAN and lithium negative electrodes was tested using the in-situ thickness swelling measurement device MCS1000 (IEST).

3.Material Characterization: SEM, XPS, Raman, NMR.

Result Analysis

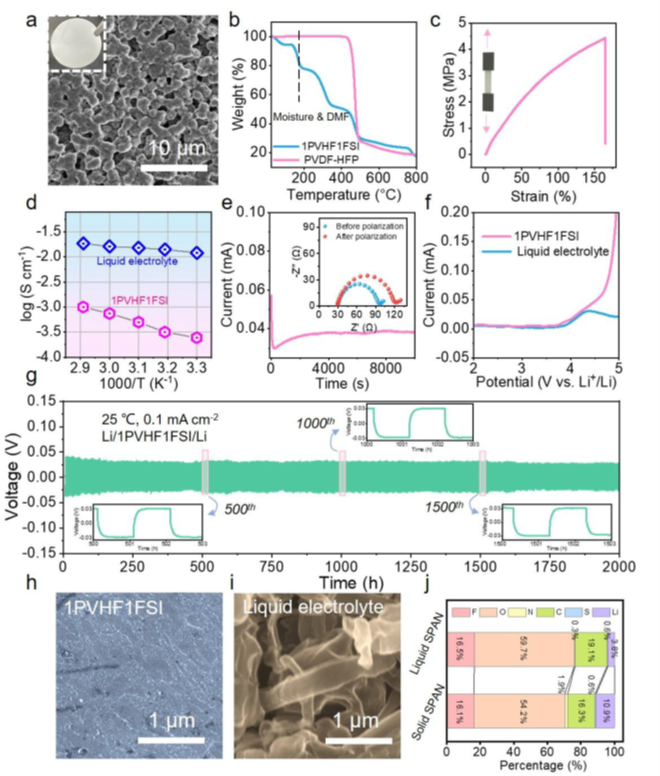

Figure 1.Performance characterization of solid electrolyte membrane 1PVHF1FSI in Li-SPAN battery

The author characterizes the performance of the solid electrolyte membrane 1PVHF1FSI in Li-SPAN battery in many aspects, it is found that it has a continuous porous channel, which can provide a good ion conduction path, and its good mechanical properties can inhibit the growth of lithium metal dendrites. The storage mechanism of lithium-ions in 1PVHF1FSI-based solid Li-SPAN batteries is different from that in liquid Li-SPAN batteries, subsequent authors characterized the polarization voltage, CV curve, cycle capacity, and rate performance of the three electrode materials, it is further clarified that solid-state SPAN has better cycle stability and rate capability due to high redox kinetics and low volume change.

D

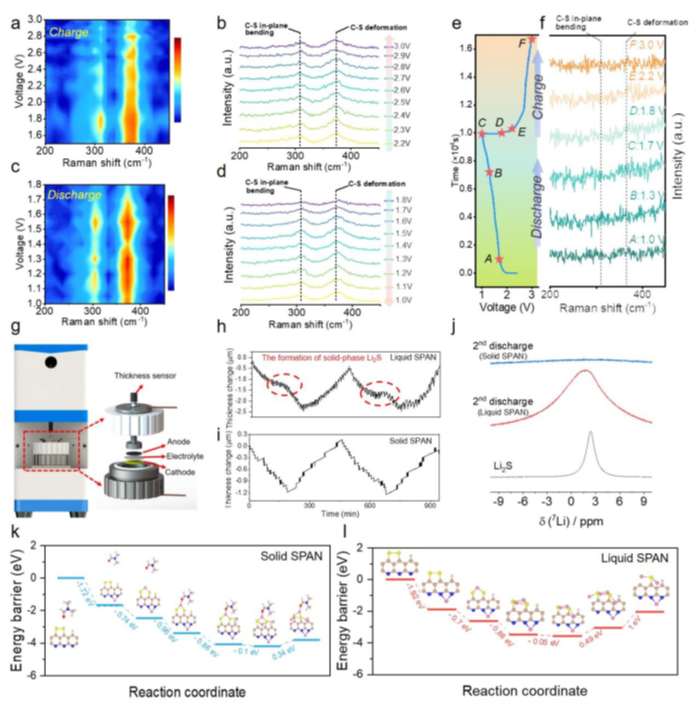

Figure 2.Analysis of the storage mechanism of Li in solid-state SPAN

The author further analyzed the storage mechanism of lithium-ion in solid-state SPAN through in-situ raman and in-situ swelling thickness test devices. It was found that in solid-state SPAN, Li4S2-PAN structure was formed as Li ions broke the S-S bond when stored in solid-state SPAN,this process is like a lithium intercalation reaction, so the authors call this mechanism a quasi-intercalation reaction.

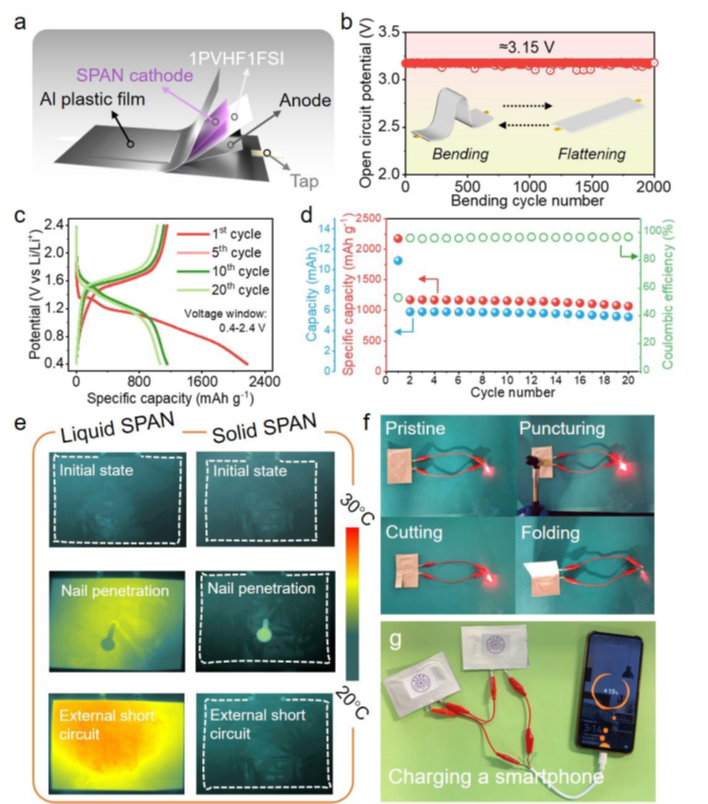

Figure 3.Performance characterization of solid SPAN pouch batteries

After analyzing the reaction mechanism, the author assembled solid-state and liquid SPAN soft-pack batteries to characterize their cycle stability and bending performance, it is found that the solid-state SPAN battery has good flexibility, the capacity retention rate is equivalent to the buckle performance, and the thermal stability of the electrolyte is also very good, which can withstand the influence of short circuit or needle stick.In practical applications, it can also charge smartphones.

Summarize

This article describes the development of a solid-state Li-SPAN battery with a salt-encapsulated high-molecular-weight polymer electrolyte. In this structure, S is immobilized in the PAN substrate during cycling, preventing the formation of Li2S and resulting in faster redox kinetics and less volume change in terms of performance compared to traditional solid-state Li-S battery systems.This work provides a new approach to improving the sulfur redox kinetics of solid-state Li-S batteries.