A Method for Comprehensive Electrochemical Properties of Solid Electrolytes

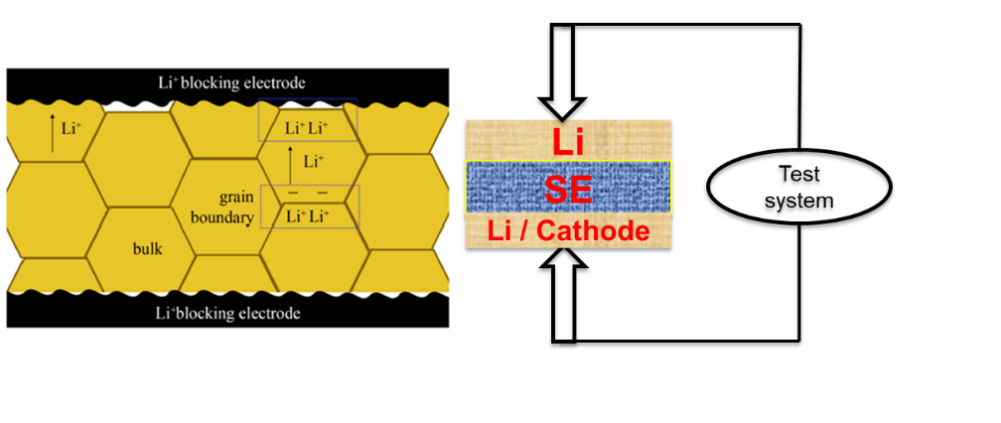

In the rapid development of lithium industry, improve the energy density and safety of battery is an important research direction of lithium researchers, all solid state battery is considered to be the most future application potential of high safety, high specific energy secondary battery, solid electrolyte (Solid Electrolyte, abbreviated as SE) is the main core components, and used to judge the solid electrolyte performance of the main performance index for ion conductivity, electronic conductivity and interface stability (according to the published group standard solid state lithium battery with solid electrolyte performance requirements and test method). On the one hand, the density, roughness and integrity of the pressed solid electrolyte sheet determine the conductivity of the solid electrolyte and its whole-cell cycle performance; on the other hand, the stable and uniform force during the test can ensure the accuracy of the test results. Therefore, the production and testing systems that can exert stable and standardized pressure are crucial to the development of solid electrolytes and their lithium-metal batteries.

Figure 1.Schematic diagram of the testing of solid-state electrolytes

1.Test the Equipment

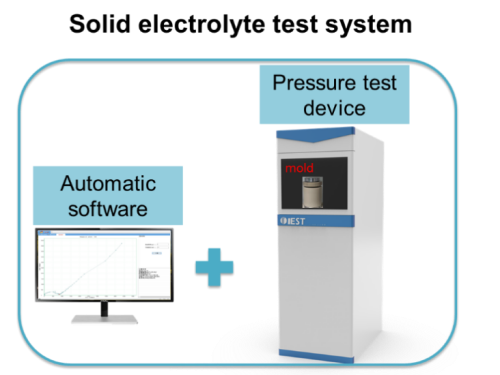

Solid electrolyte test system SEMS1100 (jointly developed by IEST and Xiamen University), is a multi-functional test dedicated to solid electrolyte samples, integrating pressure plate, testing, calculation of the automatic chemical performance of solid electrolyte measurement equipment. The system adopts an integrated structure design, including pressurized module, electrochemical test module, density measurement module, ceramic sheet pressing and clamping module, etc., which is suitable for the testing of various oxides, sulfide, polymer and other solid electrolytes.

Figure 2. Schematic diagram of the solid-state electrolyte test system equipment

2.Application Direction

2.1 Powder Production

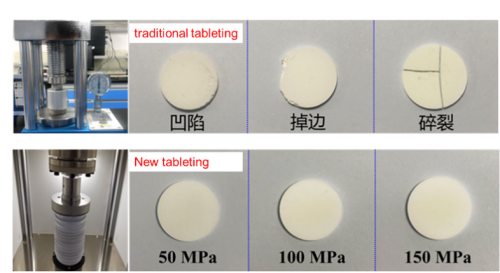

To evaluate the electrochemical properties of solid electrolyte powder, And the samples with poor interface contact also need to spray a conductive metal on the surface as an ion blocking electrode, The force application and uniformity will greatly affect the integrity of the prepared ceramic sheet, Figure 3 shows a macro picture of ceramic pieces obtained from different pressing devices, The uniform force application of SEMS1100 equipment is used to prepare the solid electrolyte ceramic sheet, Complete and uniform samples in different pressure ranges, Reduce the risk of sample destruction, Improve the yield and test efficiency.

Figure 3. Comparison of the production results of different devices

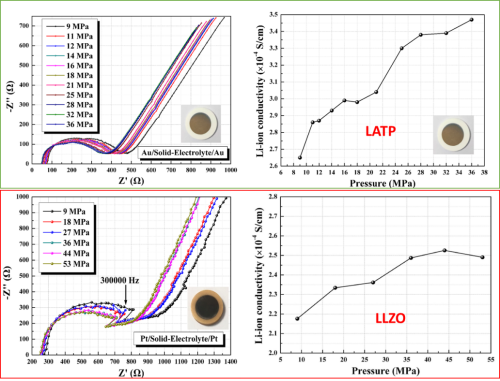

2.2 Lon Electrical Conductivity

The two different solid electrolyte materials Li1.3Al0.3Ti1.7 (PO4) 3 (LATP) and Li6.5La3Zr1.5Ta0.5O12 (LLZO) and their electrochemical impedance spectrum and ionic conductivity change, as shown in Figure 4, by applying different quantitative pressure to the sandwich ceramic tablets and measuring their electrochemical impedance spectrum, the test pressure can affect their ionic conductivity to varying degrees, which indicates the necessity to test the electrochemical properties of the solid electrolyte by applying stable quantified pressure.

Figure 4. Electrochemical impedance spectra of two solid electrolytes and their ionic conductivity to pressure

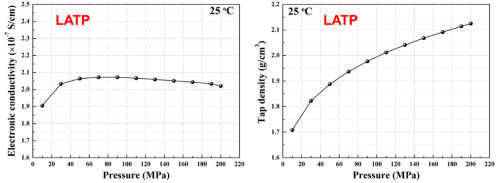

2.3 Electron Conductivity & Compaction Density

Through the SEMS 1100 equipment, the electronic conductivity and compaction density of the LATP powder can be tested simultaneously during the lampressing process, and it is found that the compaction density ranges from the initial 1.7g / cm with the increase of the applied pressure3 Increase it to 2.1g / cm3 However, the electron conductivity is stable at around 50MPa, that is, the density and electron conductivity trend of the solid electrolyte materials are not completely consistent, indicating that under different pressure conditions, different tests are necessary to synchronize the characteristics of the solid electrolyte to obtain comprehensive and accurate measurement results.

Figure 5. LATP Change of electron conductivity and compaction density of solid electrolyte

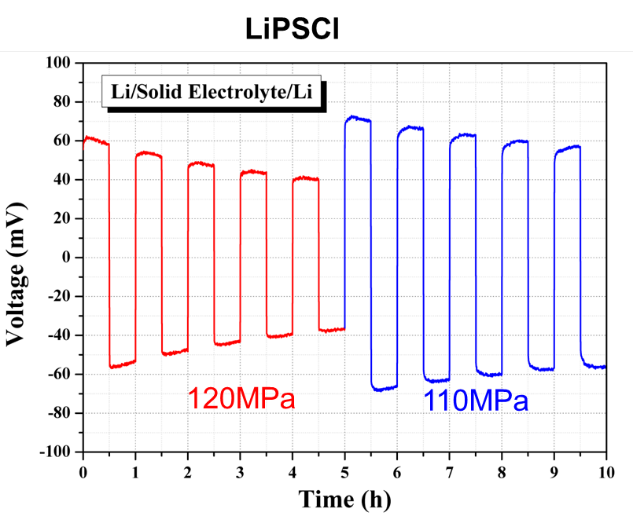

2.4 Recycling Performance of Solid-state Lithium Metal Battery

Li-SE-Li symmetrical battery is assembled in the SEMS 1100 matching sealing device, apply different pressure respectively, test the circulating deposition of lithium metal, measure the potential change of symmetrical battery, you can see that when the applied pressure drops from 120MPa to 110MPa, the overpotential of the battery increases significantly, which shows that the deposition behavior of lithium metal battery is relatively sensitive to the pressure change, and it is important to evaluate the interface stability of solid electrolyte by changing the applied pressure.

Figure 6. Cycle charge and discharge test of a symmetrical battery

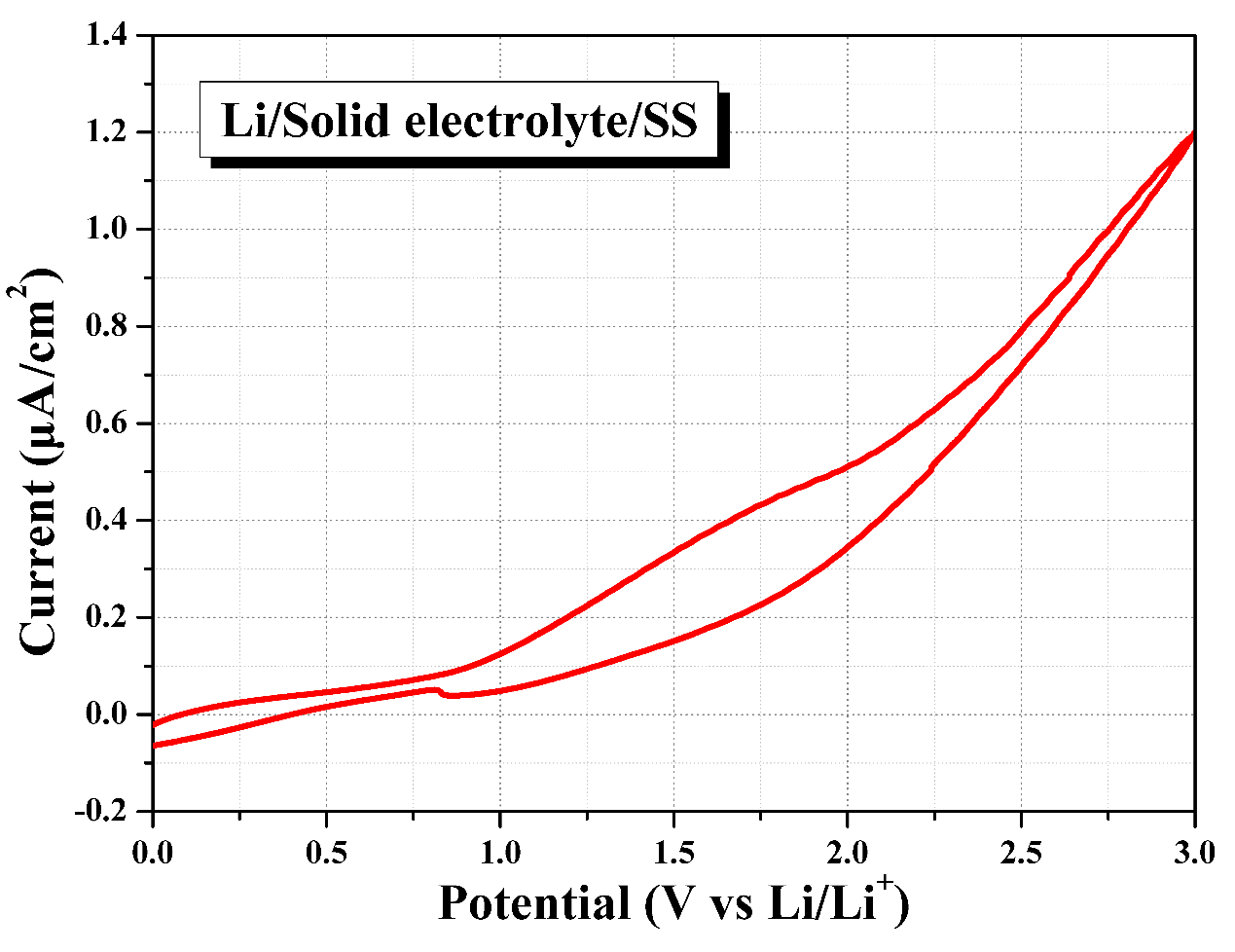

2.5 Electrochemical Stabilization Window

The Li-SE-stainless steel battery is assembled in the SEMS 1100 matching sealing device, and the cyclic voltammetry tests its redox potential. It can be seen that when the overpotential rises to 3V, the oxidative current density of the battery is only about 1.2 A cm-2 this shows that the solid electrolyte is relatively stable in a voltage window of 0~3V, that is, the pressurization and sealing electrochemical test of different solid electrolyte materials and their lithium metal batteries can be realized through the SEMS 1100 equipment.

Figure 7. Electrochemical Window Test of Solid-state Electrolytes

3.Summary

This paper using solid electrolyte integrated test system SEMS1100, for all kinds of solid electrolyte materials, plate and electrochemical performance test, can be accurately evaluated under different quantitative pressure conditions on the solid electrolyte ion conductivity, electron conductivity, compaction density, electrochemical window, and lithium metal battery interface stability and cycle performance, for researchers to understand and develop solid electrolyte material, to accelerate the solid electrolyte research.

Reference Documentation

1. Huang Xiao, Wu Linbin, Huang Zhen, et al. Electrochemical test methods in Ion Solid and Electrolysis Research, Energy Storage Science and Technology, 2020,9 (2): 479-500.

2. Yong-Gun Lee, Satoshi Fujiki, Changhoon Jung, et al.High-energy long -cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes.2020, 4(5): 299-308.

3. Nicholas Williard a, Chris Hendricks a, Jaesik Chung, et al.Effects of external pressure on phase stability and diffusion ratein lithium-ion cells.Journal of Electroanalytical Chemistry, 2021, 895, 115400.

4. T / SPSTS 019- -2021; Performance Requirements and Test Methods of Solid State Electrolytes for Solid State Lithium Battery; Inorganic oxide; Solid State Electrolytes for Solid State Electrolytes.