Graphite Electrode Sheet Rebound and Resistance Properties Are Evaluated in Different Pressing Methods

Battery energy density has always been one of the hotspots of lithium ion battery research, choose high capacity of positive and negative material, improve the compaction density can greatly improve battery energy density, but high compaction density often affect the battery ratio performance, even bring safety risks, so seek appropriate compaction density is of great significance for battery design. Because the actual battery production of the pole plate is usually roller, but some laboratories in the preparation of small plate, and the test pole resistance is vertical leveling, these two ways to the direction of graphite particles may be different, so this paper by comparing the leveling and roller pressure on the pole compaction density and resistance, to provide battery designers with reference data support.

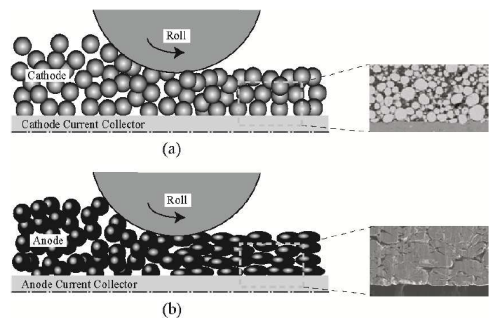

Figure 1.Diagram of positive and negative pole sheet roller pressure

1.Experimental Equipment and Test Methods

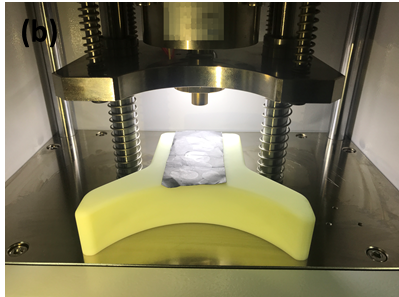

1.1Experimental Equipment: Pole sheet resistor, model BER1300, electrode diameter of 14mm, with applied pressure of 5~60MP a; the appearance of the equipment is as shown in Figure 2.

|  |

Figure 2. (a) BER1300 appearance diagram (b) BER1300 structure diagram

1.2 Test Method: Cut the pole sheet to be measured into a rectangular size of about 5cm 10cm, place it on the sample table, and set the parameters such as test pressure and pressure retention time on the M RMS software to start the test. The software automatically reads the pole sheet thickness, resistance, resistivity, conductivity and other data.

1.3 Test Parameter

①. Test the rebound amount of lower plate under different pressure.

②. Apply the unrolled plate and then repress, to compare the resistivity of the two.

③. Test the resistivity under different pressures on unrolled and rolled poles.

2.Data Analysis

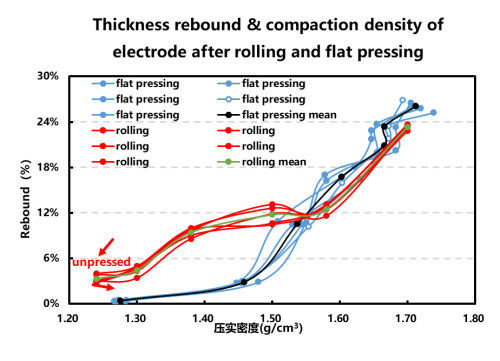

2.1 Comparison of the Rebound Amount of Pole Sheet Thickness of Two Different Pressing Methods

As shown in Figure 3, when the flat pole plate thickness is low, and the rebound amount increases from the 0.4% under the low pressure to 26% under the pole plate thickness increases to 24%. The above phenomenon shows that in the range of small compaction density, although there is a lateral shear force, the rebound between the particles is greater than that after the pressure relief. With the increase of the compaction density, the pole thickness rebound after the two methods is basically the same.

Figure 3. Comparison of the thickness rebound amount of roller pressure and flat pressure plate

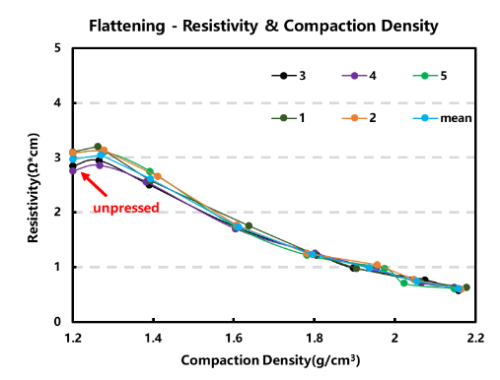

2.2 Comparison of Resistivity of Leveling and Voltage Test Plates

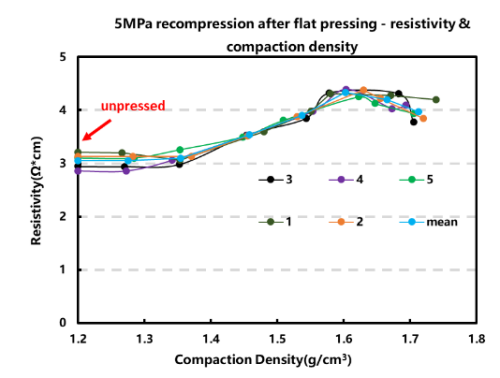

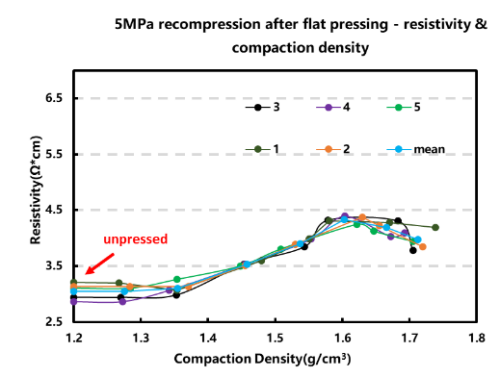

Comparing the difference, as shown in Figure 4, the resistivity of the pole decreases after the compression density of 5MPa, the electrode resistivity increases, but the compaction is greater than a certain value. This phenomenon is mainly due to the different pressure, with the increase of the contact resistance of the electrode and the electrode surface and the electrode coating particles also decreasing, and with 5MPa test different pressure plate resistivity, although the contact resistance between the particles in the electrode coating decreases, but the contact resistance of the test electrode and the electrode surface increases, instead makes the total resistivity increased with the compaction density.

|  |

Figure 4. (a) resistivity & compaction density after leveling; (b) resistivity & compaction after pressing

2.3 Comparison of Electric Resistivity after Leveling Pressure and Roller Pressure

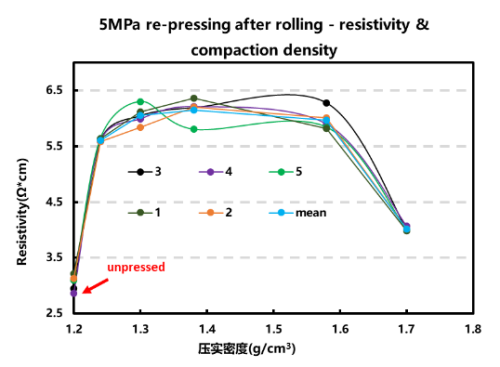

The resistivity of the pole plate and the roller pressure is tested as shown in FIG. 5. After the revoltage of the pole plate increases and then decreases with the compaction density, and the resistivity will be higher than the resistivity of the pole plate under the same compaction density. The above phenomenon may be that the influence of the electrode surface state is greater than the flat pressure, so that the contact resistance between the test electrode and the electrode surface is greater, or that the roller pressure mode will cause the graphite layer to slide and more less conductive base surface is arranged in parallel, so that the electrode resistivity is larger.

|  |

Figure 5. (a) R R & compaction after leveling; (b) R & compaction after roller pressing

3.Summary

This paper evaluates the rebound amount and resistance performance of graphite anode. It is known from the above experimental data.

1.The rebound amount of flat pressure and roller pressure is varies different.

2.If the electrode sheet after leveling pressure and recompression increases with the compaction density, the resistivity trend is opposite, which may be related to the increasing contact resistance between the test electrode and the electrode sheet surface after leveling pressure.

3.For the leveling and roll pressure of the electrode plate, the resistivity of the repressing test electrode plate is found that with the increase of compaction density, the change trend of the resistivity of the two pressing plate modes is similar, and the resistivity after the pressing plate is greater than before the pressing plate, and the roller pressing mode will increase the resistivity of the electrode plate greater.

Based on the above results of different plate methods on thickness rebound and resistivity, we can further combine X RD, S EM and other characterization methods for further in-depth analysis.

Reference Material

1.Sang Gun Lee, Dong Hyup Jeon.Effect of electrode compression on the wettability of lithium-ion batteries.Journal of Power Sources 265(2014) 363-369.

2.Xu Jieru, Li Hong, etc., electrical conductivity test and analysis methods in lithium battery research [J]. Energy Storage Science and Technology, 2018,7 (5) 926-955.

3.Wu Xiangkun, Zhan Qiuset, Zhang LAN, Zhang Suojiang. Progress in microstructure optimization and controllable preparation technology of lithium battery electrode sheet [J]. Applied Chemistry, 35 (9): 1076-1092.