Investigating the Correlation Between Battery Compression Performance and SOC and SOH

With the rapid development of electric vehicles, the share of electric vehicles on the road is also increasing. While providing convenience to people, there are inevitably many safety hazards. Among them, car collision accidents are safety issues that need to be focused on. Lithium-ion batteries are energy storage devices for electric vehicles, storing huge amounts of energy. Although the lithium-ion battery is installed in a position that is not easy to deform on the chassis of the car, once it is hit, it is very likely to damage the battery and cause short-circuit failure,eventually lead to fire or even explosion, posing a great threat to people's life and property safety. Therefore, it is necessary to clearly and accurately understand and systematically study the mechanical properties of lithium-ion batteries, and to clarify the mechanical responses of lithium-ion batteries under different impact or compression conditions.

The mechanical performance test of lithium-ion batteries is an important means to study its various mechanical properties, and the research content is usually realized around multiple scales, mainly combining the hierarchical routes of microscopic scale, mesoscopic scale, macro single scale and macro system scale. Figure 1 is a schematic diagram of multiple scales of a lithium-ion battery, each scale is relatively independent and directly affected. From the perspective of a lithium-ion battery cell, it is mainly a sealed complex body composed of cathode and anode sheets, diaphragm, electrolyte, aluminum-plastic film or steel shell. Each component has different mechanical properties, and with charge and discharge cycles and aging, the state of its internal components is constantly changing. In this paper, the in-situ swelling analysis system of IEST is used to monitor the battery pressure and thickness deformation by associating the parameters of the single battery SOC and SOH, the correlation evaluation of the compression performance of the battery provides a feasible method for the study of the mechanical properties of lithium-ion batteries in different states. The compression performance index actually measured by this method can also be used as an effective theoretical support data for battery simulation.

1.Experimental Equipment and Test Methods

1.1 Experimental Equipment

In-situ Swelling Analyzer, Model SWE2110 (IEST), As Shown in the Figure Below:

Figure 2. Appearance of SWE2110 Equipment

1.2 Test Information and Process

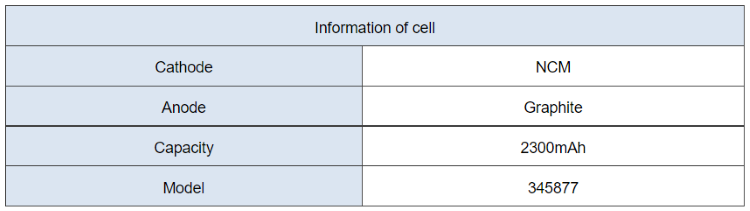

1.2.1 The Battery Information is Shown in Table 1.

Table 1. Test Battery Information

1.2.2 Charge and Discharge Process

1.2.3 Experimental Process: Battery compression modulus test: Put the battery to be tested into the corresponding channel of SWE2110, open the MISS software, set the pressure control process, sampling frequency, charge and discharge process, etc, the software automatically reads the battery thickness, thickness change, Test temperature, current, voltage, capacity and other data.

2.Experimental Results and Analysis

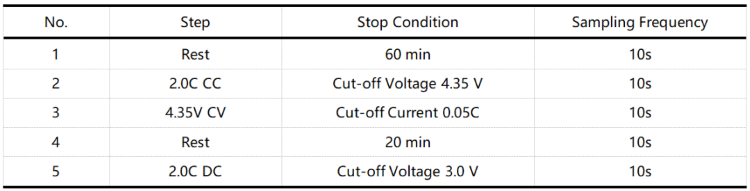

The in-situ swelling analyzer (SWE2110) turns on the compression test (steady state) mode, and sets the pressure adjustment method as shown in Figure3 (a): The initial pressure is 10kg, the pressurization step is 100kg, and each pressure is maintained for 10S until 1000kg, and then release the pressure, the pressure relief step is 100kg, and each pressure is maintained for 10S until the experiment is completed at 10kg. Select three fresh batteries, adjust different SOC states (0%, 50%, 100%), and adjust the pressure according to Figure3(a) to conduct steady-state compression experiments on the three batteries. The results are shown in Figure 3(b): during the pressurization stage, as the pressure continued to increase, the thickness of the battery was continuously compressed; during the depressurization stage, as the pressure continued to decrease, the thickness of the battery continued to rebound. At the same time, it was found that the compression degree of the battery is different in different states.

As the SOC increases, the battery is more easily compressed. This may be related to the inconsistency and inhomogeneity of the performance of the positive and negative active materials in different lithium-intercalation states. The interior of the battery electrode will also change under different SOC. For example, for graphite electrodes, with the embedding of different amounts of lithium, the graphite lattice expands by 10% along the c-axis, and graphite is often arranged parallel to the current collector, so graphite electrodes mainly expand and contract in the thickness direction. This volume change in turn causes microscopic particles and pores to slightly deform and reorder each other during (de)lithiation, affecting ion and electron transport, as a result, inhomogeneity of SOC and volume change occurs in the thickness direction, and even the top electrode shrinks and the bottom electrode expands on the electrode surface. In addition, the elastic modulus, Poisson's ratio, and density of graphite and LCO materials will change under the condition of different lithium intercalation amounts, resulting in different mechanical properties.

At the same time, the battery is charged and discharged at a high rate. Based on the initial capacity, when the battery capacity drops to 85% of the initial capacity, the battery health status is set to 85% SOH. Similarly when the capacity is 80%, the battery health status is 80% SOH. Comparing Figure 3(b) (c) (d), it can be found that under different SOH conditions, the compression degrees of different SOC batteries are different. This shows that the compressive modulus of the battery is not only related to the SOC, but also to the SOH state of the battery. And with the aging of the battery (in this experiment, the aging rate of charging and discharging was increased), the influencing factors of SOC tend to weaken gradually. During cyclic aging, battery performance continues to decline due to various mechanical and chemical processes. The battery cell degradation mechanisms include current collector corrosion, morphological changes of active materials, electrolyte decomposition, solid electrolyte interface (SEI) layer formation, and material dissolution. In addition, mechanical damage to the battery can also accelerate chemical degradation, such as in this intercalation process, where the volume change induces considerable stress inside the particles, leading to mechanical failures such as comminution or cracking and fracture of the active material. These cracks create new surfaces on the particles, which are then exposed to the electrolyte, leading to additional SEI layer formation and capacity fading. These attenuation conditions also affect the swelling and contraction process of the electrodes.

Figure 3. (a) Pressure regulation mode (b) (c) (d) Compression modulus curves of batteries under different SOH

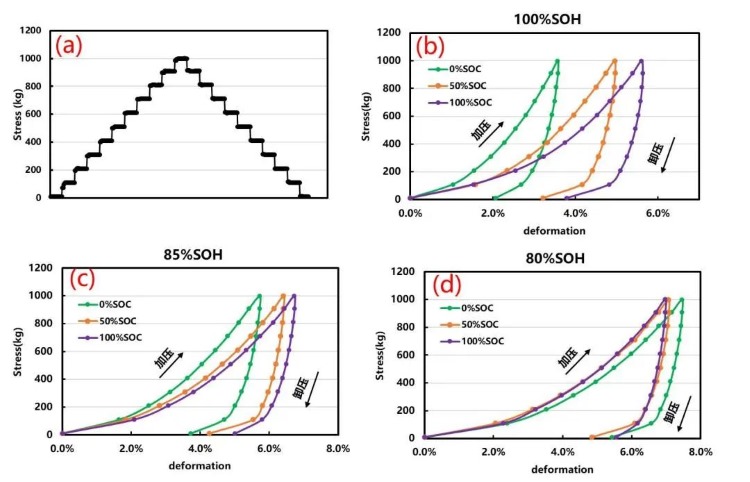

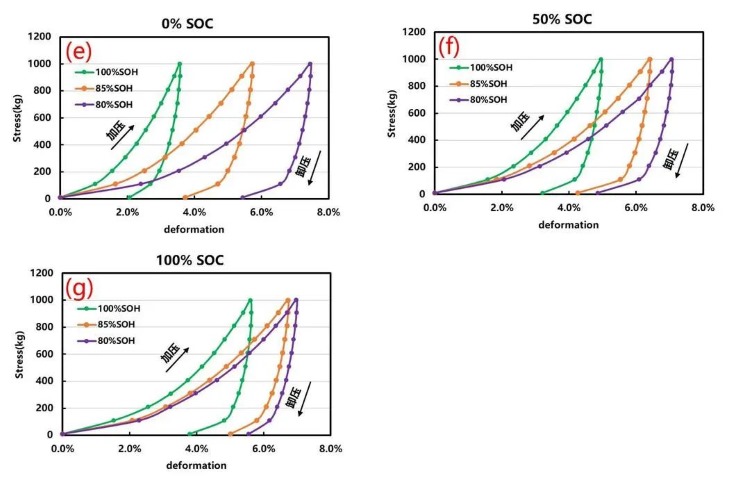

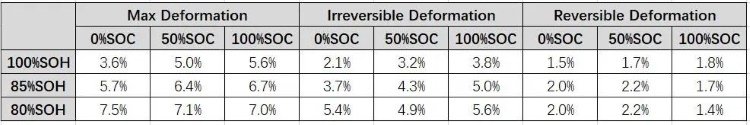

Further, under the same SOC state, the battery compression performance under different SOH is compared. The relationship between the battery compressive modulus and SOH is shown in Figure 4: As the SOH decreases, the maximum deformation increases, the compressive modulus decreases, and the irreversible deformation also increases, as shown in Table 2. This may be related to the continuous rapid lithiation/delithiation of positive and negative active materials when the battery is aging at a high rate, not only does it cause structural changes, fragmentation, and dissolution of the active material, but it is also accompanied by various side reactions, leading to SEI film growth, negative electrode lithium deposition, and battery gas production.

Active material fragmentation, SEI film growth, and lithium precipitation increase the irreversible deformation of the battery, and because the compressive modulus of the SEI film and lithium dendrites is much smaller than that of the cathode and anode, the maximum compressive deformation of the battery after aging increases significantly. In addition, side reaction gas production will also change the contact tightness of the cathode and anode sheets, thus affecting the compression performance of the battery. In short, the compressive modulus of the battery is closely related to the SOH of the battery.

Figure 4. Battery Irreversible Thickness Change Curve

Table 2.Summary of Battery Compression Performance

3.Summary

In this paper, the in-situ swelling analyzer(SWE) of IEST is used to analyze the correlation between the compression performance of the ternary/graphite system battery and the SOC and SOH. Experiments show that the compression performance of the battery is not static, but changes with factors such as SOC and SOH. The corresponding correlation can design more reliable products for relevant technicians, provide more real data for simulation technicians, and improve the simulation effect.