Differences in Stiffness between Battery Cell Swelling and Compression

Lithium-ion batteries have the advantages of high working voltage, high energy density, wide operating range, stable discharge, and high specific power. They are currently widely used in power vehicles, 3C digital products, energy storage equipment and other fields. As the requirements for lithium-ion battery terminal products continue to increase, the performance of lithium-ion batteries also needs to be continuously improved, such as the structural stability, safety performance, appearance hardness, etc. of lithium-ion batteries. Improving the stiffness of the battery core can not only beautify the appearance, but also improve the safety performance of the battery core, such as the impact of hard objects, falling from high altitudes, and extrusion. It also plays a vital role in the safety design of the module.

The battery core stiffness generally includes compression stiffness and expansion stiffness. Compression stiffness refers to the elastic deformation ability of the battery core when it is not charging or discharging, and expansion stiffness refers to the battery core's ability to resist elastic deformation during the charging and discharging process. At present, the usual testing method is to squeeze the battery core and record the corresponding relationship between the compression displacement and pressure of the battery core, thereby obtaining the compression stiffness of the battery core under different extrusion deformations and using the compression stiffness to approximately equal the expansion stiffness of the battery core. This approximate solution is to determine how big the difference in cell expansion stiffness is. This article uses the in-situ expansion analysis system (SWE2110) to quantify the difference in compression stiffness and expansion stiffness of the same cell.

1.Test Information

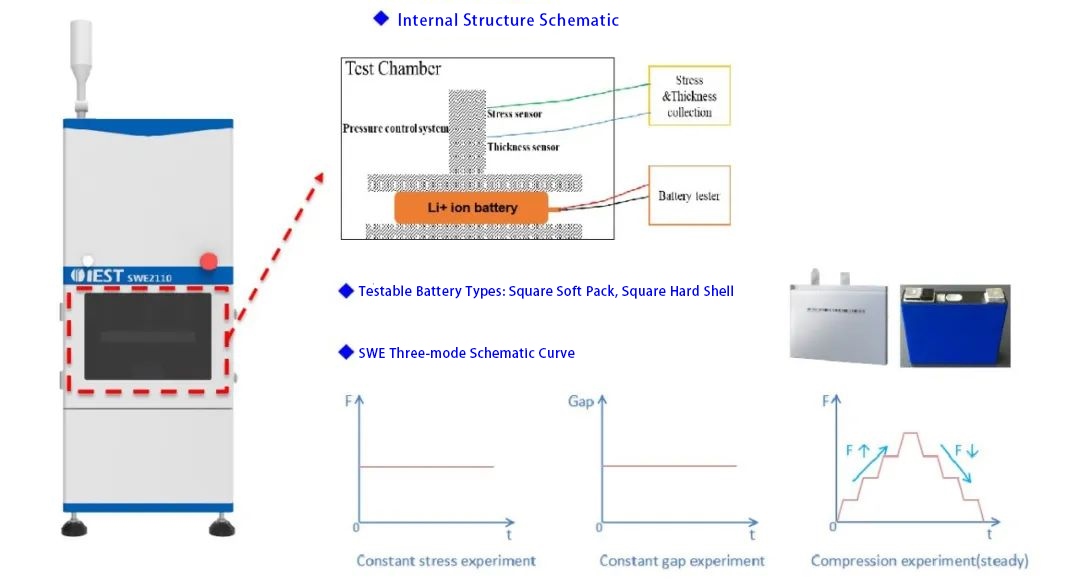

1.1 Experimental Equipment: In-situ swelling analyzer, model SWE2110 (IEST), as shown in the figure below:

Figure 1. Schematic diagram of in-situ swelling analysis system

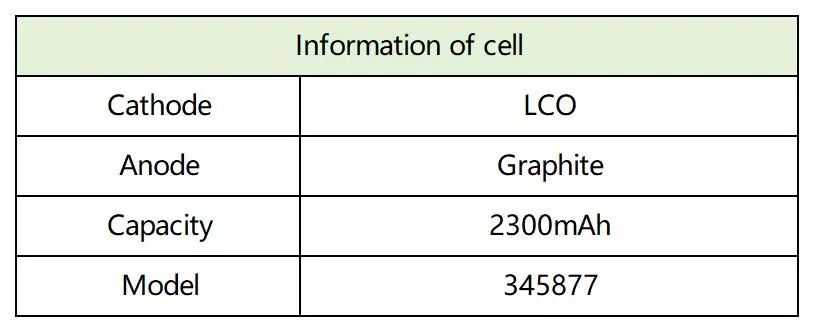

1.2 Battery Cell Information

Table 1. Battery cell information

1.3 Charge and Discharge Process

2. Experimental Data and Result Analysis

2.1 Expansion Rigidity

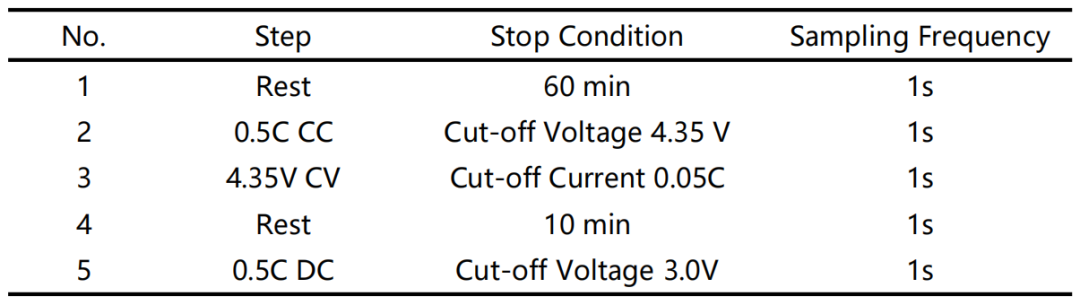

Select the constant pressure test mode for SWE2110 equipment, and set the test pressure to 10kg (0.02MPa), 30kg (0.06MPa), 50kg (0.10MPa), 100kg (0.21MPa), 200kg (0.42MPa), respectively, turn on the charging and discharging instrument to charge and discharge the battery core, and monitor the thickness of the battery core in real time and in situ under different pressure conditions as shown in Figure 2: as charging progresses, the positive electrode continues to remove lithium and the negative electrode continues to insert lithium, and the thickness of the battery core continues to increase. During the discharge process, lithium ions continue to escape from the negative electrode and insert back into the positive electrode, and the thickness continues to decrease, and the thickness of the battery core shows a decreasing trend as the pressure increases.

Figure 2. Charging and discharging thickness change curves of battery cells under different pressures

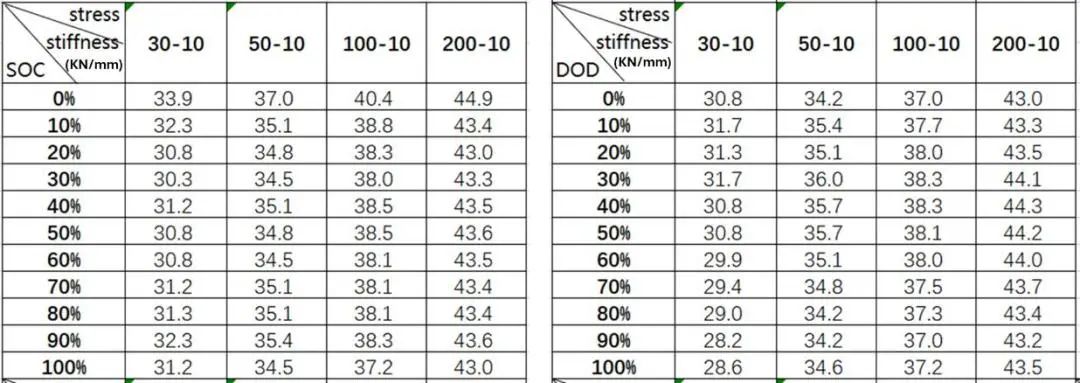

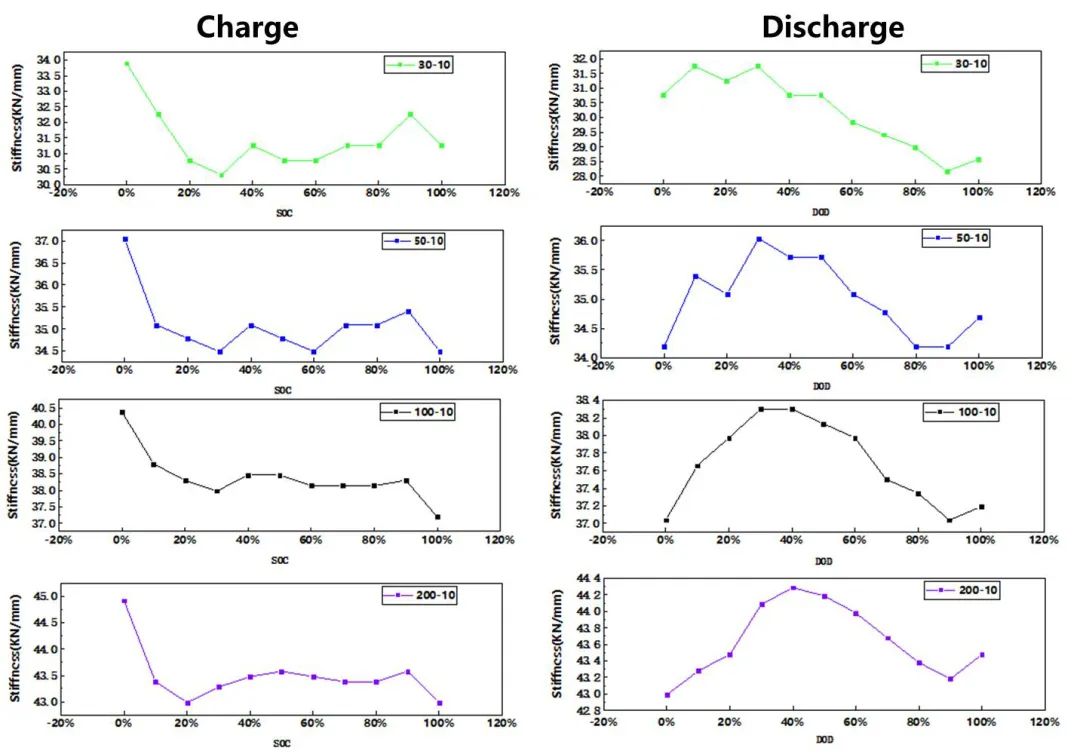

Select the thickness of the battery core under different SOC/DOD states from Figure 2, taking the initial pressure of 10kg as the benchmark, calculate the expansion stiffness of the cell in different SOC/DOD states according to the stiffness calculation formula K=ΔF/Δδ (where F is the stress and δ is the cell thickness). as shown in Table 2: As the pressure increases, the battery core shows an increasing trend in each SOC/DOD state, indicating that the expansion stiffness of the battery core is highly dependent on the amount of pressure applied. There are also differences in the expansion stiffness of the battery core in different SOC/DOD states, as shown in Figure 3 below: the expansion stiffness of the battery core is relatively large in the early stage of charging, and then the stiffness decreases and becomes relatively stable as charging proceeds; during the discharge process of the battery core, the expansion stiffness first increases and then decreases, and the maximum stiffness is reached at a discharge depth of about 30% to 50%.

Table 2. Expansion stiffness of each SOC of the battery cell (left table shows charging process, right table shows discharge process)

Figure 3. Change trend of expansion stiffness of battery cells in different SOC/DOD states

2.2 Compression Rigidity:

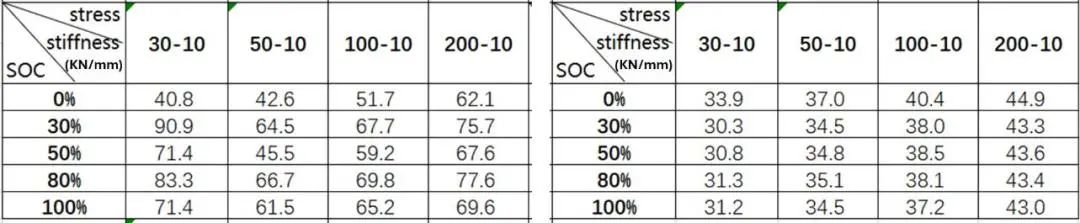

Adjust the cell SOC to 0%, 30%, 50%, 80%, and 100% respectively, and use SWE2100 to adjust the pressure to 10kg (0.02MPa), 30kg (0.06MPa), 50kg (0.10MPa), 100kg (0.21MPa), 200kg (0.42MPa) and monitor the changes in battery core thickness. The compressive stiffness of the tested battery core in each state is shown in Table 3 (left) below. There is a big difference between the compressive stiffness and expansion stiffness of the battery core. The expansion stiffness is significantly smaller than the compression stiffness. Therefore, directly using the compression stiffness to infer the expansion stiffness may result in large errors.

Table 3. Comparison of cell stiffness (compression stiffness in the left table, expansion stiffness in the right table)

3.Conclusion

This paper uses the constant pressure mode of the in-situ expansion analysis system (SWE2100) to characterize the expansion stiffness and compression stiffness of the battery core, verifying that the battery core stiffness is not only related to the battery core state, there is also a correlation with the amount of applied pressure, and there is a significant difference in the expansion stiffness and compression stiffness of the cell.

4.References

[1] Hoeschele P, Heindl S F, Erker S, et al. Influence of reversible swelling and preload force on the failure behavior of a lithium-ion pouch cell tested under realistic boundary conditions[J]. Journal of Energy Storage, 2023.

[2] Zhu Maoyu, He Jianchao, Yu Ao, et al. Test method for battery cell expansion stiffness: 202310112653[P] [2024-01-15].