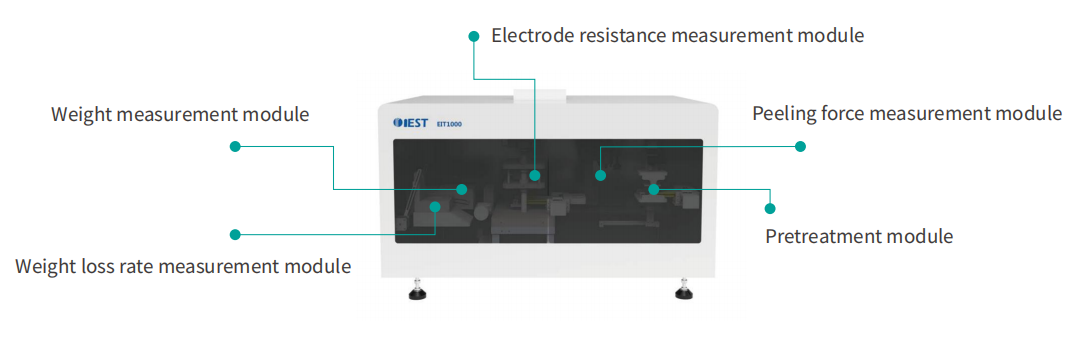

Lithium Battery Electrode Integrated Testing Equipment (EIT1000)

Brand: IEST

Product origin: Xiamen

Delivery time: About 6-8 weeks after placing the order

Supply capacity: About 20-40 sets/month

Application:Automatic detection of electrode thickness, resistance, moisture and stripping force parameters in the production line process section, and synchronous uploading of data.

Equipment Parameters

| Process | Modular | Parameter | Range |

Cold Pressing | Electrode resistance (standard configuration) | Resistance Measurement Resolution | 0.1μΩ |

| Resistance Measurement Range | 1μΩ~3100Ω | ||

| Electrode plate thickness (optional) | Thickness Measurement Resolution/Accuracy | 0.1μm/±1μm | |

| Thickness Measurement Range | 0~5mm | ||

| Peeling force (standard configuration) | Maximum Load | 50N | |

| Force Measuring Accuracy | ±0.2%F.S | ||

| Test Speed Range | 0.01~500mm/min | ||

| Speed Accuracy | ±0.5%F.S | ||

| Coating | Gram weight (standard configuration) | Weight Accuracy | 0.0001g |

Weight loss rate (also known as water content, standard configuration) | Weight Accuracy | 0.0001g |

Why Use EIT1000

At the current stage of the production line,the weight,weight loss rate and pole piece resistance of the pre-process coating & cold pressing are independently tested. The weight and weight loss rate need to be punched with a punching machine before weight measurement; But the problem is that the detection efficiency is slow, the man-hour consumption is high, the space utilization rate is low,the data needs to be integrated and analyzed later and the single item needs to be checked separately and uploaded to the MES separately.The pole piece integrated detection all-in-one machine can solve the above problems.

Traditional Method

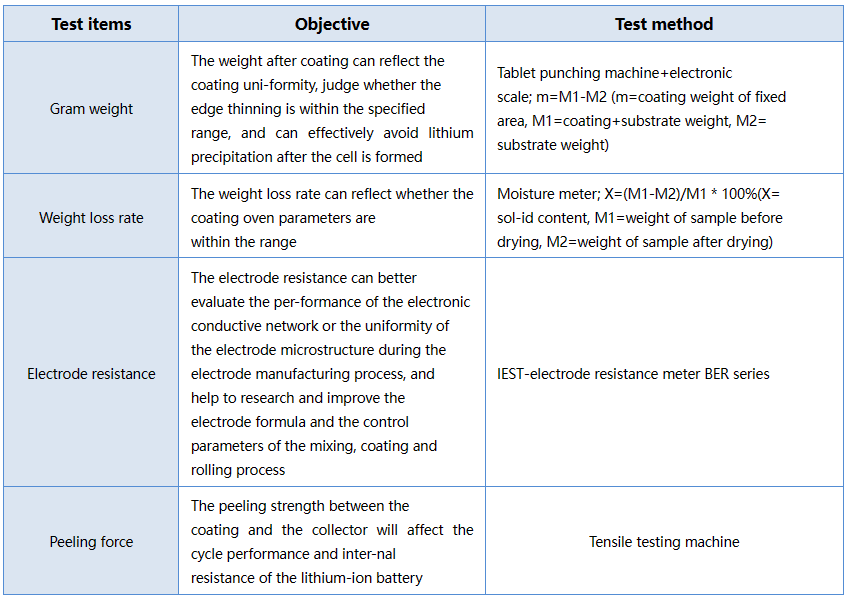

Background:Currently, each test item of electrode, gram weight, weight loss rate and electrode resistance,are independent. Moreover gram weight and weight loss rate need to be punched with a punching machine before the measurements.

Problem Points:Slow testing efficiency,high labor consumption,low space utilization,data from all testsneed to be integrated and analyzed in the later stage,and individual items need to be individually checked and then uploaded to MES.

Application

Automatic detection of electrode thickness, resistance, moisture and stripping force parameters in the production line process section and synchronous uploading of data.

Creative Solutions

1.Measurement Modularization: A certain detection module can be operated independently without mutual interference.

2.Consistency Improvement: It can reduce the difference of personnel in sample preparation and improve the consistency level of each measurement item.

3.Efficiency Improvement: Shorten testing time and improve testing frequency.

4.Optimization of Production Line Layout: Adopt integrated scheme to save space.

5.Data Traceability: Integrated analysis of measurement data to facilitate subsequent traceability.

6.Routine Check Automation: Three equipment can be checked at the same time and the routine check results can be uploaded.

7.Low Cost: It can reduce equipment management, maintenance and after-sales costs.