The Pressure Distribution System Rapidly Characterizes the Initial Flatness of the Electric Cell

In the existing process, the method of measuring the flatness of the pouch cell is mainly the visual observation method, the micrometer thickness measurement or the laser scanning method. Visual observation method is to use the visible light to observe the surface state of the cell, is a roughly but not quantitative observation method, although the visible light observation is fast, it can not quantitatively give the difference of the flatness of the cell. Laser scanning method is to use optical equipment to scan the whole contour of the cell into a 3D model, and then calculate the difference between the overall thickness value and the thickness value of the section, which can be measured quantitatively, but the equipment is expensive, with limited application【1】.

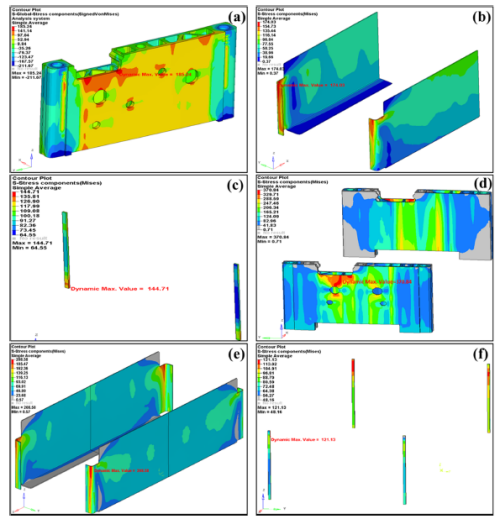

Some researchers also simulated the surface force distribution mapping of the module cell through simulation, which can also see the obvious phenomenon of the uneven pressure distribution, which on the one hand is related to the initial flatness of the cell, on the other hand is also related to the stress distribution difference caused by the uneven current density distribution in the subsequent charge and discharge process【2】. This paper uses the cell pressure distribution system (BPD1000) to monitor the pressure distribution of different positions of the cell, so as to quickly quantify and evaluate the flatness of different cell sizes.

Figure 1.Simulation of the stress distribution of the simulated module cells【2】

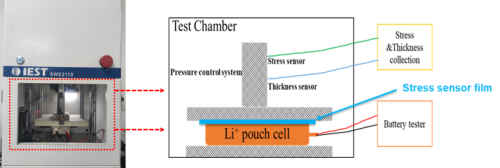

1.Test Equipment: In-situ swelling test system SWE2110, cell pressure distribution system, model BPD1000 (IEST), with a maximum pressure strength of about 8.8MPa.

Figure 2. Schematic diagram of the cell pressure distribution test.

2.Test Parameter

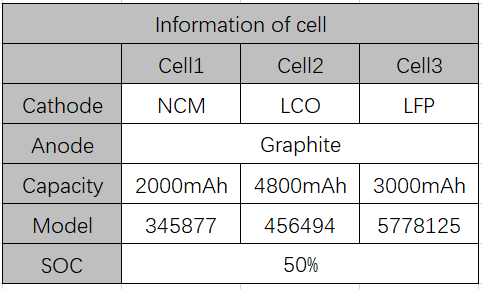

2.1 The Cell Information is Shown in Table 1

Table 1. Cell Information

2.2 Testing Process: Put the cell in the test chamber of in-situ swelling analyzer (SWE2110), place the pressure distribution film on the surface of the cell, set the constant gap mode, adjust the constant gap pressure of 300kg (i. e. apply 300kg external force to the cell), activate the pressure distribution system (BPD1000) to collect and display the surface pressure distribution data of the cell.

2.Interpretation of Result

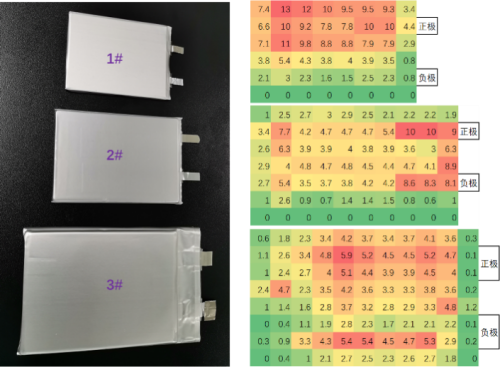

Using pressure distribution system (BPD1000) respectively test the pressure distribution of following three cells, according to 9.5*9.5mm divided into each small area, and the color scale display the cell force, as shown in figure 3: Stress distribution of three cells is inconsistent, if sum up each area force , you will find the total force will be less than 300kg, this is mainly due to the gap between the thin film sensor arrangement, and the gap pressure is not calculated.

Figure 3. Voltage and pressure change curve of the cell during charging and discharging

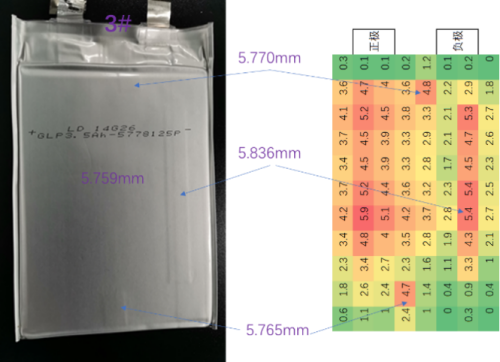

Further analysis of the surface of the different positions of the flatness reason, as shown in figure 4,3 # because the aluminum foil crater size has larger margin, cell’s head tail shows no pressure pressure . The position of the finishing tape, show greater pressure, this is likely to be one of the important factors leading to its uneven.

Figure 4. 3 # Comparison between Cell pressure distribution and Physical Cell

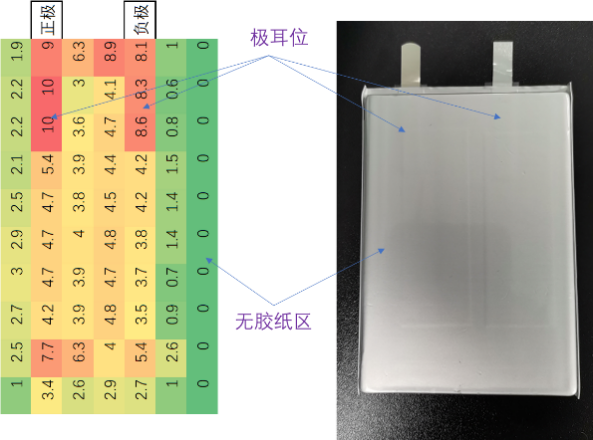

Analysis of the pressure distribution of 2 # cell is shown in Figure 5: it is obvious that the position of the positive and negative tab is obvious, and the position of the edge without sticker paper is basically free, so the thickness specification of the tab and adhesive paper adhesion are likely to be one of the important factors affecting the leveling of 2 # cell.

Figure 5. 2 # Comparison between Cell pressure distribution and physical cell

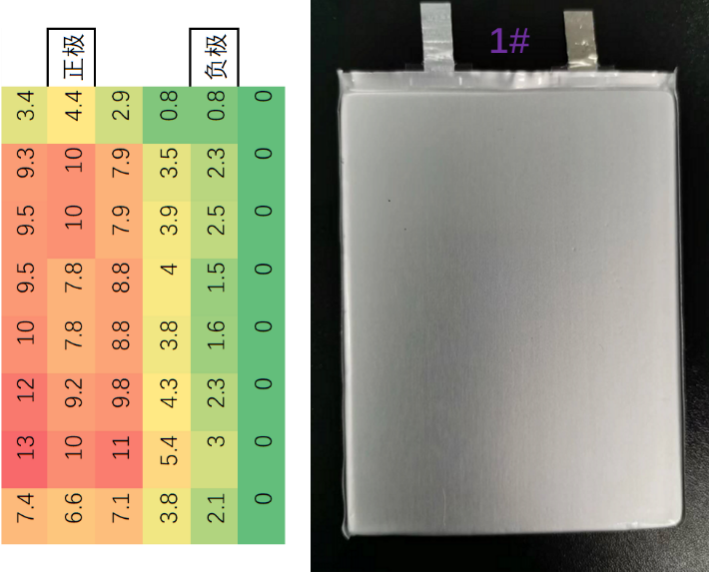

For 1 # cells did not show a similar correlation with 2 # and 3 # cells, indicating that there are other deeper design factors besides the tape and tab factors. Relevant technicians can conduct a deeper analysis accordingly.

Figure 6. 1 # Comparison between Cell pressure distribution and physical cell

Set the initial pressure of 300kg to measure the pressure on the cell surface in a constant gap mode. In this case, the uneven thickness of the cell will lead to the uneven distribution of the testing pressure. The uneven thickness or pressure distribution mainly include: (1) Uneven electrode thickness cause the in-flatness of cell. Generally speaking ,the positive and negative electrode thickness is 100-200 μm. If the thickness deviation of positive and negative electrode is greater than 5 μm, and the number of positive and negative electrode is 41 pcs, the thickness deviation can reach to 0.2mm; (2) Uneven thickness of Separator, aluminum-plastic film causes uneven cell; (3) Electrode and Separator are not close enough. Generally speaking, after the lamination, the cell will be thermoflat shaping treatment, Thermal pressure shaping can make the electrode and the Separator overlap more closely and reduce the gap, Thus reducing the battery internal resistance. At the same time, it will also improve the uniformity of the cell thickness; (4) During the process of cell injection sealing, due to low vacuum degree, Sealing and vacuum will be incomplete, The presence of gas in the aluminum-plastic film can also lead to the uneven thickness of the cell; (5) Swelling after absorption of conductive agent and binder, it increase the cell thickness. If the conductive agent and binder are not evenly distributed within the electrode, It may also lead to uneven cell thickness; (6) The electrolyte decomposes in the process of pre-charging and aging, Gas production may also lead to an uneven cell thickness.

When the thickness of the cell is not uniform, the electrode will be subjected to different aluminum-plastic film shell pressure in the process of charge and discharge, which may lead to the uniformity of charge and discharge state, and reduce the capacity and stability of the battery. Therefore, the flatness needs to be controlled to improve the consistency in the design and manufacturing. Special attention on processes include: (1) Electrode coating and roll pressure thickness needs to be controlled to improve the thickness uniformity; (2) Suitable thermal pressing process to improve the thickness uniformity; (3) Aluminum-plastic film punching and assembly process to ensure the cell flatness; and (4) Good liquid injection fluid sealing process to ensure the removal of internal air and electrolyte uniformity.

Summarize

This paper describes the surface flatness of the pouch cell by using the pouch cell pressure distribution system (BPD1000). From the result analysis, there is a certain correlation between cell process design and cell pressure distribution (flatness). Technicians can formulate appropriate distribution standards through the pressure distribution system to monitor the batch stability of the shipped cell.

Reference Documentation

1.Bo Xu Ren Zhengxin Zheng Yanjun Ma Hua Liu Feng Wang Chiwei. Method for quantitatively determining the cell flatness [P]. China: CN112665548B, 2022.5.

2.Yongkun Li, Chuang Wei, Yumao Sheng, Feipeng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries,Ind. Eng.Chem. Res,2020, 59, 27, 12313–12318.