The Impact of Conductive and Binder Materials on the Compression and Compaction Performance of NCM Powders

In the field of energy development, lithium-ion batteries have advantages such as low cost, environmental friendliness, high specific energy, light weight, and no memory effect, gradually becoming an important component of power supplies (medical equipment, entertainment equipment, computers, communication equipment, electric vehicles, aerospace vehicles, etc.). The cathode active material of lithium-ion batteries often uses transition metal oxides, such as layered lithium cobalt oxide, lithium nickel oxide, lithium nickel cobalt oxide or lithium iron phosphate, etc. The negative electrode often uses graphite, silicon-based materials, etc. as the active material.

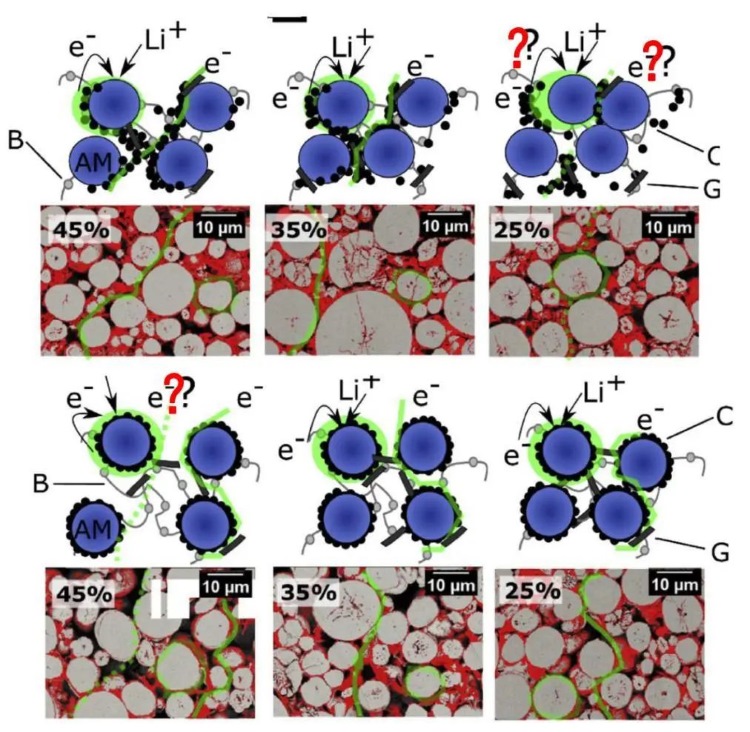

During the R&D and production process of lithium-ion batteries, it was discovered that the conductivity of the positive and negative active material particles cannot meet the requirements of electron migration rate. Therefore, conductive agents need to be added during the battery manufacturing process. The main function is to improve the electronic conductivity. The conductive agent plays a role in conducting electrons and collecting microcurrents between active material particles and between active material particles and current collectors, thereby reducing the contact resistance of the electrode and effectively reducing the polarization phenomenon of the battery. Commonly used conductive agents in lithium batteries can be divided into traditional conductive agents (such as carbon black, conductive graphite, carbon fiber, etc.) and new conductive agents (such as carbon nanotubes, graphene, and their mixed conductive slurries, etc.). Figure 1 is a schematic diagram of the distribution of conductive agents in lithium-ion battery electrodes.

Figure 1. Schematic diagram of the distribution of conductive agents in lithium-ion battery electrodes[1]

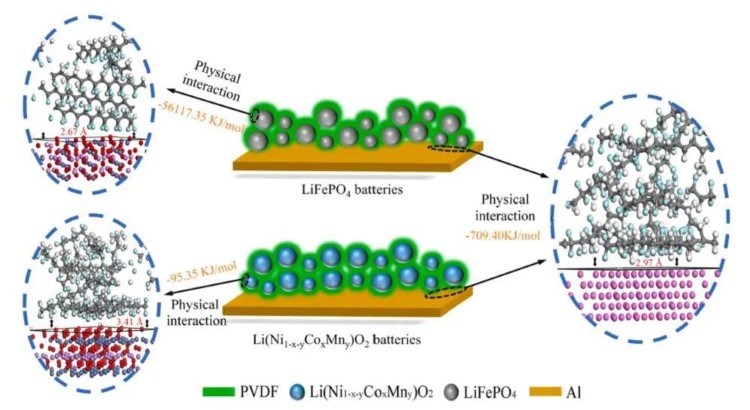

The main function of the lithium-ion battery binder is to bind the active material powder together, the binder can tightly attach the active material and conductive agent to the current collector to form a complete electrode, prevent the active material from falling off and peeling off during the charge and discharge process, and can evenly disperse the active material and conductive agent, this forms a good electron and ion transport network to achieve efficient transport of electrons and lithium ions. Commonly used binders include polyvinylidene fluoride (PVDF), carboxymethylcellulose (CMC), styrene-butadiene rubber (SBR), polyvinylpyrrolidone (PVP), polymethylmethacrylate (PMMA), polyacrylonitrile (PAN), polyacrylic acid (PAA), etc. The action mechanism of binders in lithium-ion battery research has always been the focus of everyone's attention. Zhong et al.[3] used density functional theory (DFT) simulation calculations to analyze the binding interaction between active particles and binders, and explored the binding mechanism. The results of process simulation and theoretical calculations show that in the LFP system, the binding effect between LFP and PVDF is much greater than the binding effect between PVDF and Al, while in the NCM system, the binding effect between NCM and PVDF is weaker than the binding effect between PVDF and Al; Scanning electron microscopy and Auger electron spectroscopy (AES) analysis also showed that PVDF has good bonding properties in NCM batteries. Figure 2 shows the possible combination mechanisms of PVDF in different battery systems.

Figure 2. Schematic diagram of possible binding mechanism of PVDF in lithium-ion batteries [2]

In lithium-ion battery powder research, compaction density is closely related to the energy density of the battery. During the lithium-ion battery design process, the initial focus was on the compaction density of the pole pieces. With the development of the industry, the compaction density of positive and negative electrode powders has gradually become a key reference indicator for process modification and sample batch stability monitoring. At present, the evaluation of compacted density of single powder has become relatively mature, but the correlation between the compacted density of powder and the compacted density of pole pieces is still the focus of industry researchers. Since the research process is greatly affected by the process ratio, the current research results on the correlation between powder and pole pieces have not been clearly concluded. Compared with single powder, lithium-ion battery pole pieces contain auxiliary materials such as conductive agents, binders and other additives, its impact on the comprehensive compaction density cannot be ignored. This article focuses on NCM materials. With reference to the premixing part of the dry mixing process, powder premixing of NCM+PVDF and NCM+PVDF+SP is carried out respectively, In addition, PRCD series equipment was used to evaluate the compaction density and compression performance of different mixed powders to further clarify the differences in compaction and compression performance before and after mixing the powder.

1.Testing Methods

1.1 Test Equipment: Use PRCD3100 (IEST) series equipment to evaluate the compaction and compression performance of powder materials.

Figure 3. PRCD series appearance & structure diagram

1.2 Sample Preparation and Testing: Fully mix the mixed powders with different proportions according to the ratios of NCM:PVDF=19:1 and NCM: PVDF: SP=18:1:1 respectively and carry out the powder compaction density and pressure relief rebound in the range of 10-350MPa and steady state stress and strain performance testing.

2.Test Results

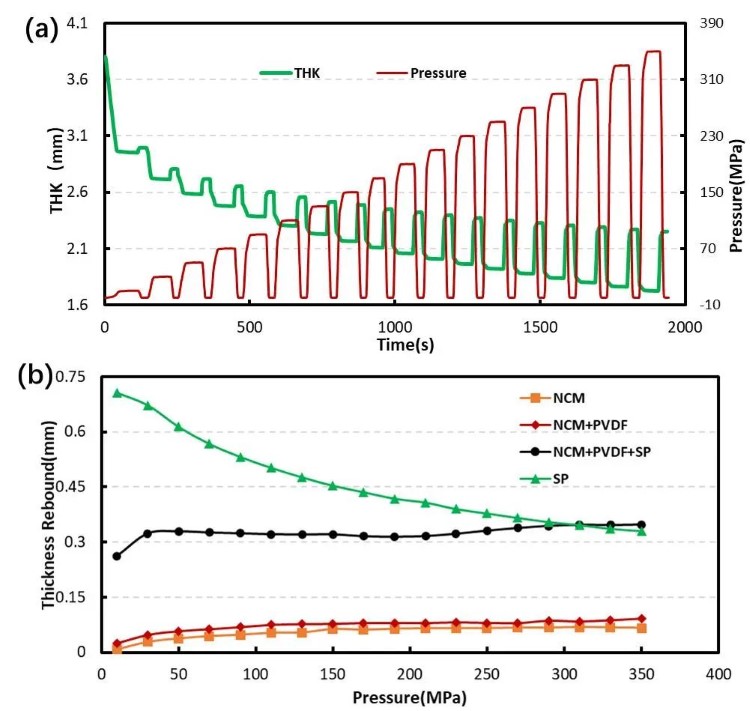

This article uses a dry powder mixing experiment to simulate the slurry making and proportioning process of the pole piece process, and then conducts powder compression and compaction performance tests on SP, NCM and mixed powders NCM+PVDF and NCM+SP+PVDF respectively. As shown in Figure 4 (a), the thickness of different powders is monitored in the pressure and pressure relief mode. The absolute value of the pressure relief thickness minus the pressure thickness is defined as the thickness rebound of the material, figure 4(b) shows the comparison of the rebound of different materials under pressure and pressure relief conditions. Judging from the test results, SP powder has the largest rebound amount, followed by NCM+SP+PVDF mixed powder, while NCM and NCM+PVDF mixed powder have very small rebound amounts. Comparing single NCM powder and mixed powder, under the same test conditions, the thickness rebound amount of the mixed powder after adding PVDF slightly increased, while the thickness rebound amount of the mixed powder after adding PVDF and SP at the same time increased significantly, the main consideration is the change caused by adding SP with a larger thickness rebound. In addition, as the pressurization pressure increases, the rebound thickness calculated after the SP powder is depressurized shows a downward trend, as the pressurization pressure increases for both NCM and NCM-based mixed powders, the rebound thickness after pressure relief first increases and then becomes stable. Parallel samples were tested on each powder, and the results were consistent.

The compression and compaction process of powder is related to the flow and rearrangement of powder, elastic and plastic deformation, crushing and other phenomena, directly affected by many factors such as powder particle size and distribution, particle shape, surface roughness, particle strength and toughness, additives, etc., the differences in the test results of different powders during the pressure relief experiment are also related to it. Conductive carbon black SP is a kind of amorphous carbon, which is composed of primary particles (primary structure) with a diameter of about 40nm that are aggregated into primary aggregates (secondary structure) with a diameter of 150-200nm. it is then processed through soft agglomeration and artificial compression. The whole carbon black particle has a grape chain-like structure and a single carbon black particle has a very large specific surface area. In lithium-ion batteries, SP is dispersed as primary aggregates of 150~200nm around the active material to form a multi-branched conductive network, thereby reducing the physical internal resistance of the battery and improving electronic conductivity. Due to this morphological structural feature, the interaction between SP nanoparticles is relatively strong, and a relatively large elastic strain will accumulate during the compression process, and a large thickness rebound will occur after pressure relief. Active NCM is micron particles with a relatively high elastic modulus, small elastic strain during compression, and small rebound thickness.

Figure 4. Pressure relief test: (a) Pressure changes in pressure relief mode; (b) Thickness rebound curve

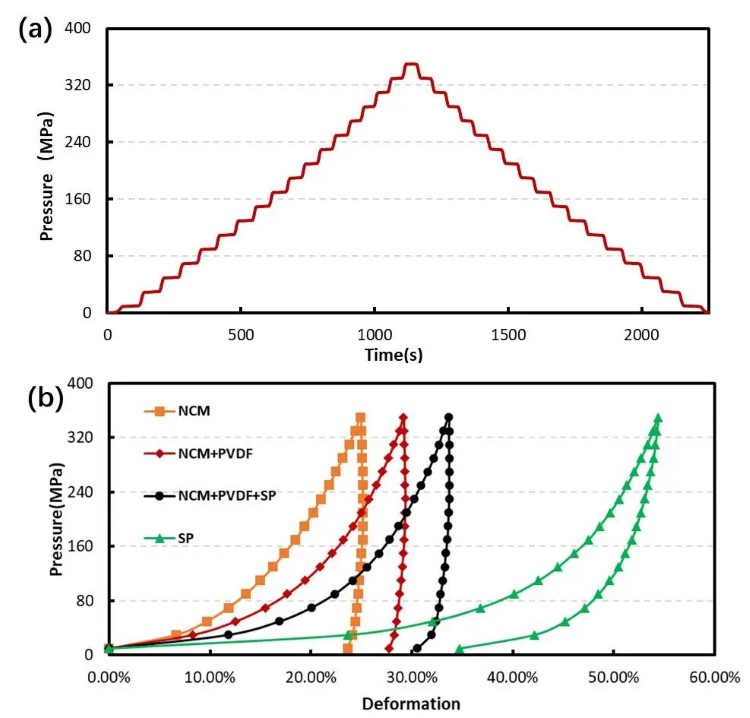

To further explore the possible correlation, this article combined the steady-state experimental mode to further test the stress strain and compacted density properties of different powder materials. As shown in Figure 5(a), pressurization and pressure relief are performed under steady-state pressure to monitor the thickness of different powders. Taking the thickness under the initial pressure of 10MPa as the basic thickness, the thickness deformation of different powders under pressure or pressure relief conditions was calculated, and the stress strain curves of different powder materials shown in Figure 5(b) were obtained. A summary of the maximum deformation, reversible deformation and irreversible deformation results of different materials is shown in Table 1. It can be clearly seen from the stress strain curves of different powders that there are significant differences between the powders. After the materials are pressed to the same pressure, the maximum deformation amount is SP>NCM+PVDF+SP>NCM+PVDF>NCM, irreversible The same trend exists for both deformation and reversible deformation. It can be further clarified through the difference in stress-strain curves that premixing SP and PVDF powder with NCM can directly cause changes in the material's stress-strain properties, and this change is consistent with the results of pressure relief measurements. This shows that when PVDF powder is added to NCM powder, since the PVDF granular powder has a certain elasticity, the compressive strain of the mixed powder will be increased, and the irreversible strain will also increase slightly. The SP nanoparticles with hyperbranched chain structure have the largest compressive strain and the largest rebound. When they are added to NCM powder, the stress-strain curve of the mixed powder changes greatly, and both the reversible strain and irreversible strain increase significantly. This shows that the conductive agent SP has a relatively large impact on the compaction density of the mixed powder or electrode.

Figure 5. Steady state test: (a) Steady state mode pressure change; (b) Stress strain curves of different powders

Table 1. Comparison of deformation data for different powders

According to the compression process of the mixed powder mentioned above, the actual powder filling process under pressure is closely related to the particle size distribution, morphology and other factors of the powder material, during the production process of pole pieces, compression is actually reflected in the flow rearrangement, elasticity and plastic deformation processes of the powder. In addition to being directly related to the physical properties of the main material powder, the additives and moisture in the process ratio are also key influencing indicators. Common additives that affect powder compression and compaction properties mainly include flow aids, binders and conductive agents, the binder is a soluble polymer material with bonding effect. In the actual pole piece process, it is wrapped on the surface of the active material and filled in the gaps between particles; The actual binder in the pole piece will increase the flow resistance and reduce the flow performance; in the presence of binder, different conductive agents also have different effects on the compaction density.

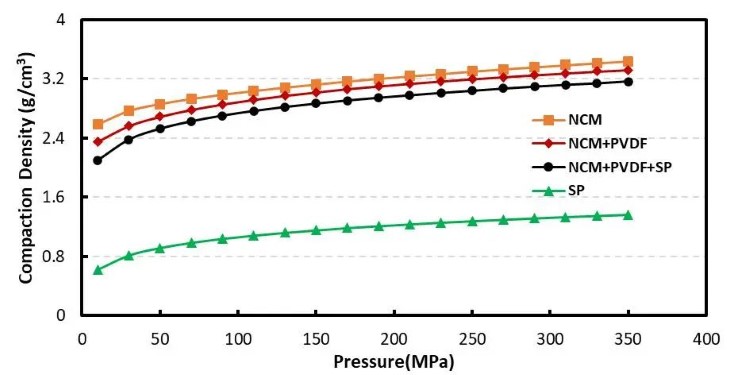

The experimental design of this article is based on the NCM basic powder. The binder PVDF and the conductive agent SP are respectively added before premixing. This is also to correlate the physical property indicators at the pole piece level from the powder level. From the compression performance test results, it can be clearly seen that the compression performance of the powder end is significantly changed after adding the binder and conductive agent. From the compaction density results, SP<NCM+PVDF+SP<NCM+PVDF<NCM, this result can also be directly related to changes in the pressure relief rebound amount and steady-state deformation amount. Taken together, the pressure required for the mixed powder after adding PVDF and SP to reach the same compaction density as that of the original NCM powder is greater, from the powder level, the two substances introduced in the experimental setting reduce the compaction density of the basic powder; from this point of view, the correlation between simple powder mixing and the compression and compaction of the pole piece needs to be further explored, the next step can be to systematically explore the compression and compaction conditions of the powder and pole pieces after the slurry is dried and dispersed, and explore a new method for predicting the performance of the pole piece level at the powder level during the process development process.

Figure 6. Measurement results of different powder compaction densities

3.Summary

This article focuses on NCM materials, with reference to the premixing part of the dry mixing process, powder premixing of NCM+PVDF and NCM+PVDF+SP is carried out respectively, combined with PRCD series equipment, the compaction density and compression performance of different mixed powders are evaluated, the difference in compression and compaction properties before and after powder mixing was further clarified, and it was clarified that the compression and compaction properties of NCM materials changed significantly after PVDF and SP were added, the process development process can be combined with current testing methods to design more reasonable experiments to evaluate the correlation between the compression and compaction performance of the powder layer and the pole piece layer.

4. Reference

[1] mikoWoo @IDEAL LIFE. Lithium-ion battery electrode sheet theory and process basis.

[2] Zhong X, Han J, Chen L ,et al. Binding mechanisms of PVDF in lithium ion batteries[J]. Applied Surface Science, 2021, 553(4): 149564.DOI:10.1016/j.apsusc.2021.149564.

[3] BRUCE P G,SCROSATI B,TARASCON J M. Nanomaterials for Rechargeable lithium batteries[J]. Angew Chem Int Ed Engl,2008,47(16):2930-2946.

[4] B K K A, A S A, A H N , et al. Internal resistance mapping preparation to optimize electrode thickness and density using symmetric cell for high-performance lithium-ion batteries and capacitors[J]. Journal of Power Sources, 2018, 396:207-212.

[5] Yang Shaobin, Liang Zheng. Principles and applications of lithium-ion battery manufacturing process.