A Method for Characterizing Slurry Conductivity and Sedimentation

Performance

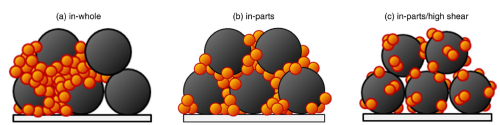

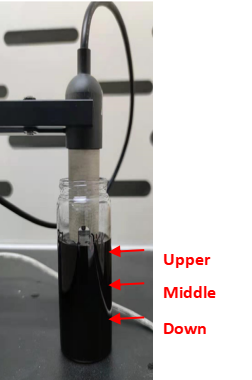

The slurry is an important intermediate product in the production of lithium-ion batteries.The uniformity and stability of the slurry greatly affect the consistency and electrochemical performance of the final battery cell.The current method of monitoring slurry only has viscosity parameters, which cannot accurately evaluate the uniformity and stability of its electrical properties.The resistivity parameters of the slurry are significantly related to the formulation of the slurry, the type and content of the conductive agent, the type and content of the binder, etc., and the slurry may have gel sedimentation if it is allowed to stand for a period of time after the completion of stirring.As shown in Figure 1,At this time, the resistivity value will also show varying degrees of change, so the slurry resistivity can be used as a method to characterize the uniformity and stability of the electrical properties of the slurry.

Monitoring the resistivity of the slurry, on the one hand, it can evaluate the influence of different active materials, conductive agents, binders, and solid content on the electrochemical performance for material evaluation and screening.On the other hand, it can also be used to monitor the stability of the process, which can quickly identify abnormalities in the mixing process, and avoid the waste of time and cost caused by defective products flowing into the subsequent process.

Figure 1. Schematic diagram of three mixing methods of LCO and conductive carbon particles

1. Experimental Equipment and Test Methods

1.1 Experimental Equipment: Model BSR2300, including 3 groups of electrode channels.

1.2 Test Method: The slurry to be tested is placed in a test bottle, and the diameter of the mouth of the bottle is required to be greater than 35mm. Insert the slurry electrode pen into the slurry, stir a little to make the electrode surface completely infiltrate the slurry, open the corresponding acquisition software, and collect the resistivity change data corresponding to each group of electrode channels in real time.

2. Paste Resistivity Test Case

2.1 Comparison of Resistivity of Conductive Carbon Paste with Different Viscosity

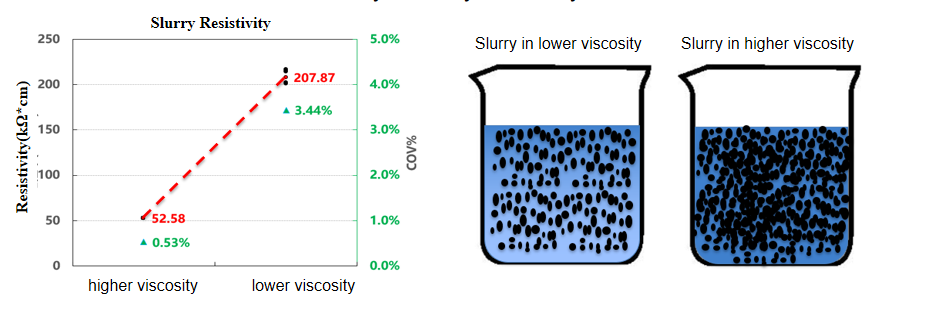

Viscosity affects the dispersion state of conductive carbon particles in the slurry. When the viscosity of the slurry is high, the contact between the particles and the dispersion state of the particles in the slurry are relatively stable.Conduct resistivity tests on two slurries with different viscosities. The resistivity of the slurry with a large viscosity is smaller than that of the slurry with a small viscosity.If in batch production of slurry, after fixing the slurry formula, the resistivity test can be performed on different batches of slurry with the same viscosity to monitor the process stability of the slurry.

Figure 2. Comparison of resistivity of pastes with different viscosities

2.2 Comparison of Resistivity of Conductive Carbon Paste with Different Dilution Multiples

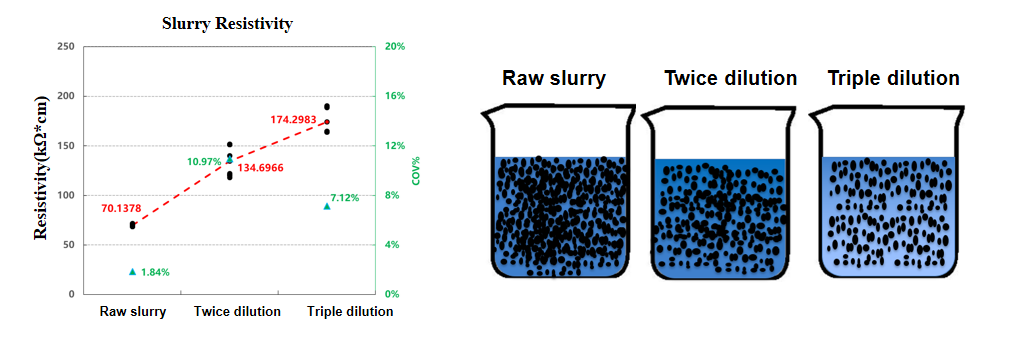

Diluting the conductive carbon slurry by different multiples can change the concentration of conductive carbon particles per unit volume and affect the dispersion state of conductive carbon particles in the slurry.. As the dilution factor increases, the concentration of conductive carbon gradually decreases and the resistivity of the slurry gradually increases. If the slurry formula is fixed in the mass production of slurry, the resistivity test can be performed on different batches of the same concentration slurry. Monitor the process stability of the slurry.

Figure 3. Comparison of resistivity of different dilution multiples of slurry

2.3 Analysis of Slurry Settlement Performance

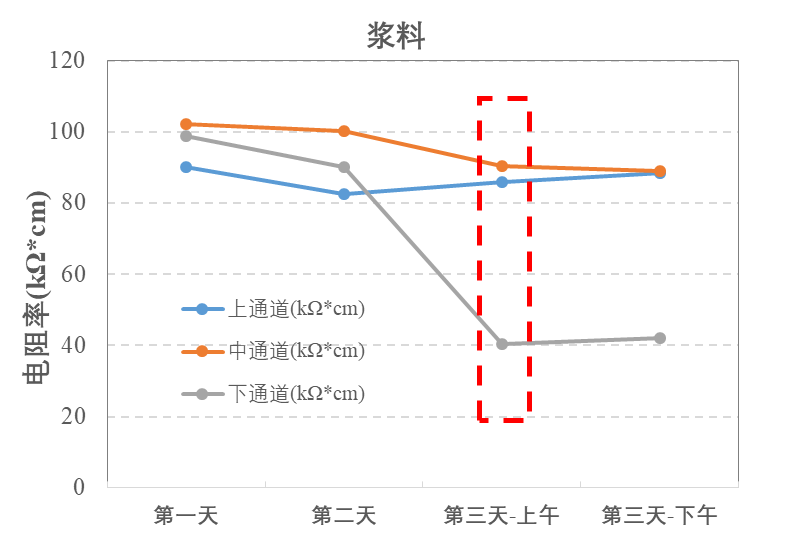

When the stirred slurry is left to stand for a period of time, the suspended particles in the slurry will settle to a certain extent. By testing the resistivity changes at different positions in the vertical direction of the slurry, the sedimentation performance of the slurry can be judged.As shown in Figure 4,the NCM811 slurry was tested for three consecutive days,In the morning test on the third day, the resistivity measured by the lower channel electrode dropped significantly, indicating that the particles in the upper layer gradually settled to the lower layer at this time.Therefore, the longest standing life of the slurry can be evaluated according to the test results of the resistivity at different times, which is convenient for the production staff to arrange the storage time of the slurry after stirring and monitor the quality stability of the slurry.

|  |

Figure 4. Paste resistivity curve with time

3.Summarize

This paper uses a slurry resistance meter to monitor the resistivity of the slurry with different viscosities, different dilution multiples and different standing times, which can distinguish the differences in the conductivity of the slurry under different formulations, different processes, and different quality states.The R&D personnel can monitor the stability of the slurry process and the longest standing time by further formulating the specification range of the slurry resistivity.

4. References

1. B.G. Westphal et al. Journal of Energy Storage 11 (2017) 76–85.

2. Kentaro Kuratani et al. Journal of The Electrochemical Society, 166 (2019) (4) A501-A506.