Description

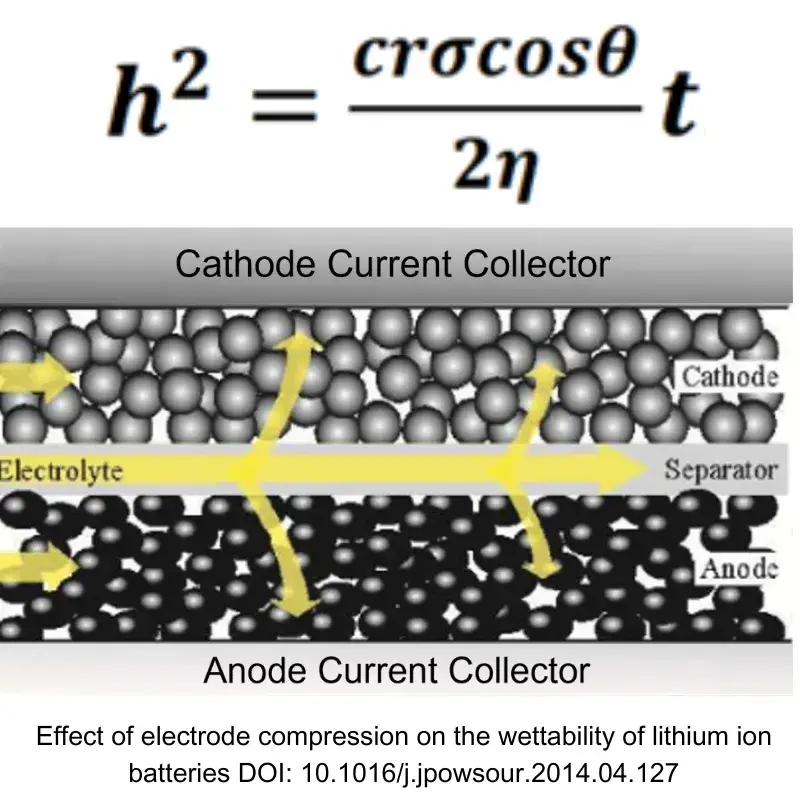

1. Principle of Electrode Wetting

The Lucas–Washburn Equation is commonly used to describe the dynamic of liquid absorption in electrode pores, as represented by the equation below:

- r represents the radius of the capillary (m),

- σ represents the surface tension of the imbibition fluid (N/m),

- η represents the viscosity of the imbibition fluid (Pa*s),

- θ represents the contact angle of the wet phase (°),

- h represents the liquid suction height (m),

- t represents the liquid suction time,

- cr represents a fixed value, called the formal radius.

2. Applications

-

Electrolyte performance evaluation

-

Electrode consistency assessment

-

Material / electrode surface-treatment process optimization

-

Battery performance prediction

-

Production process improvement

-

Research & development(R&D)

3. Electrolyte Wetting Characterization Solutions

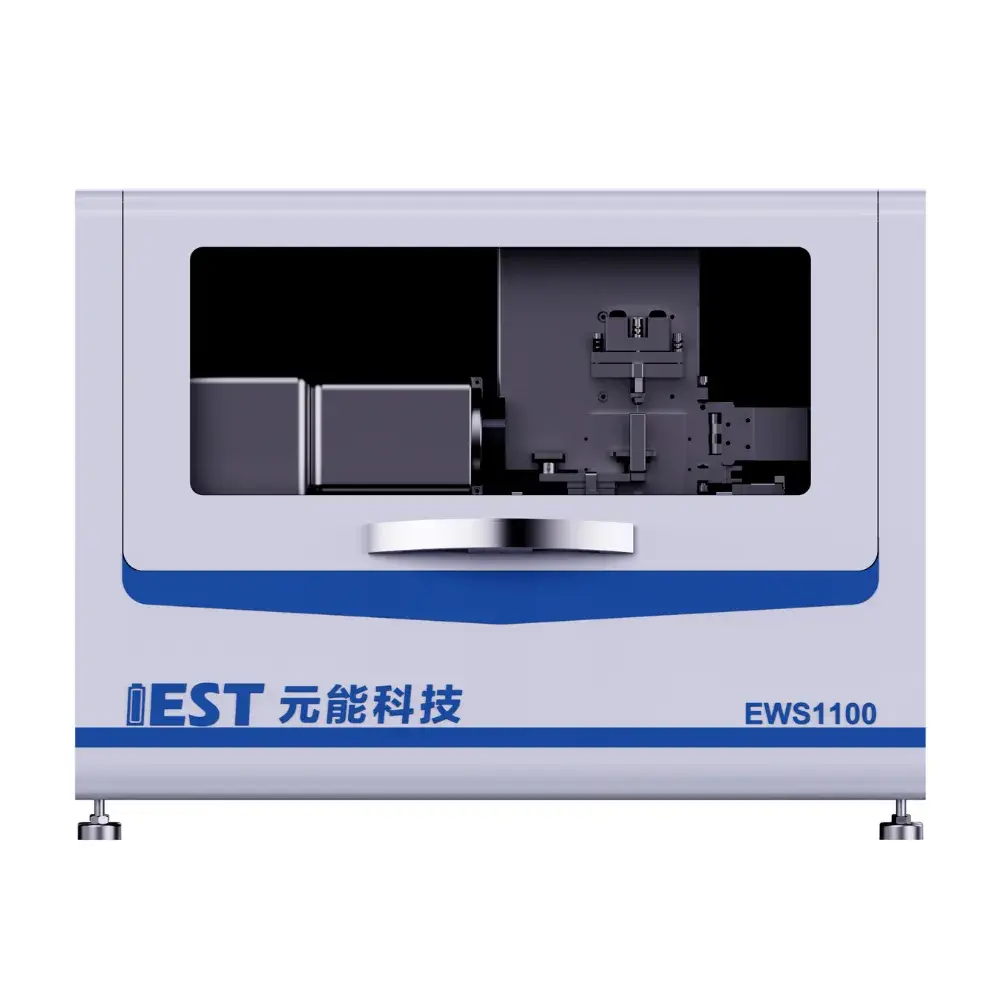

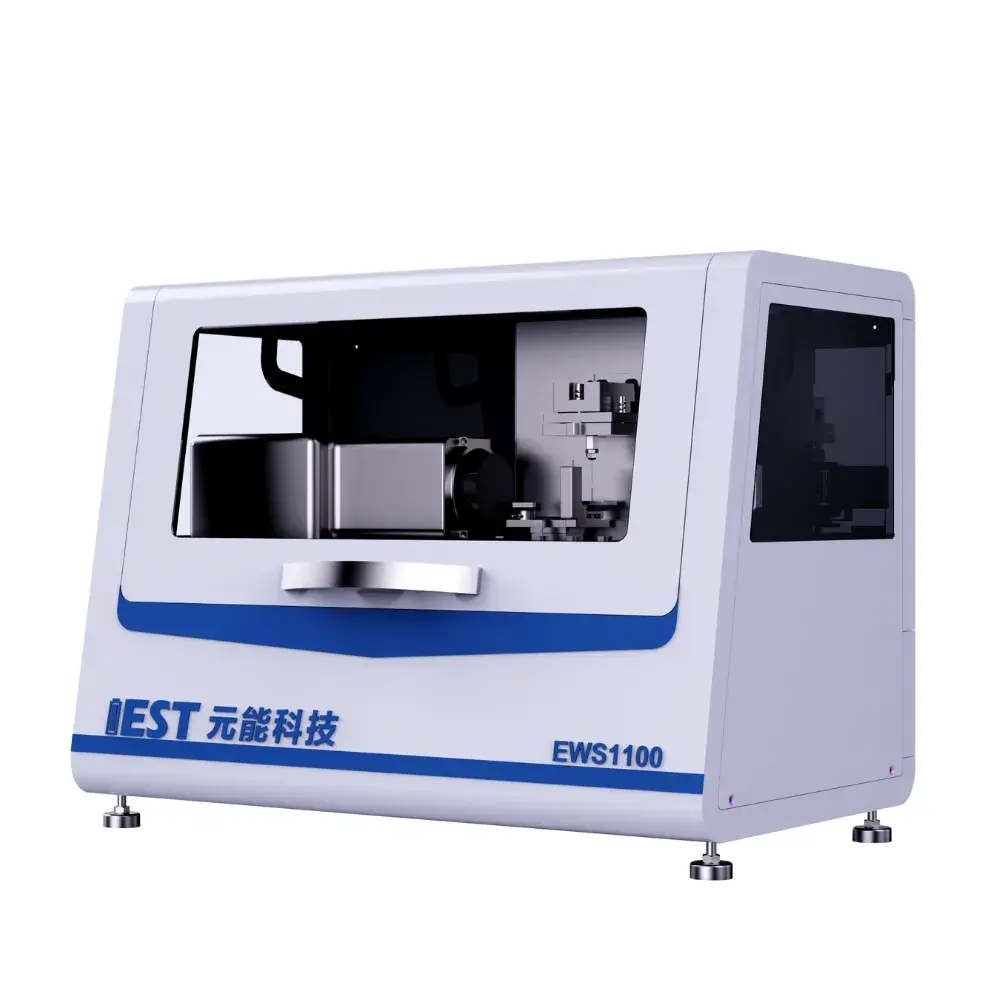

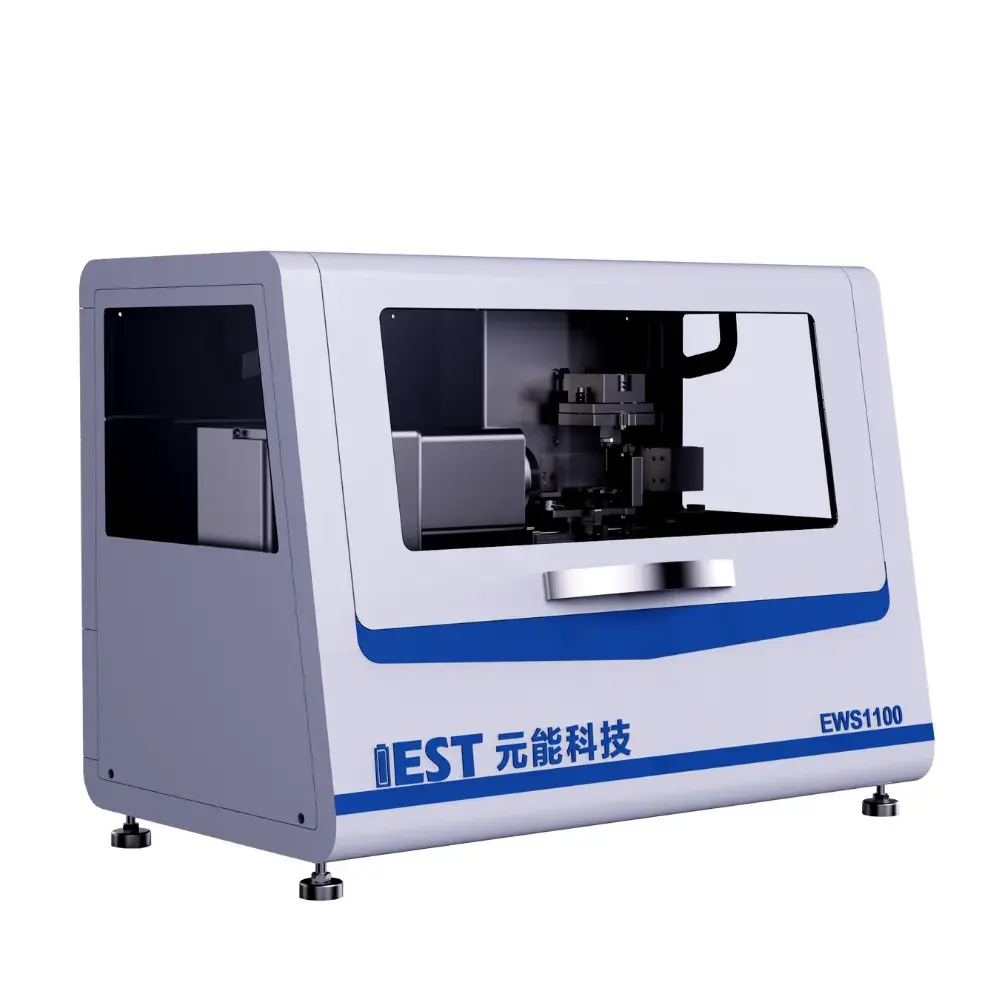

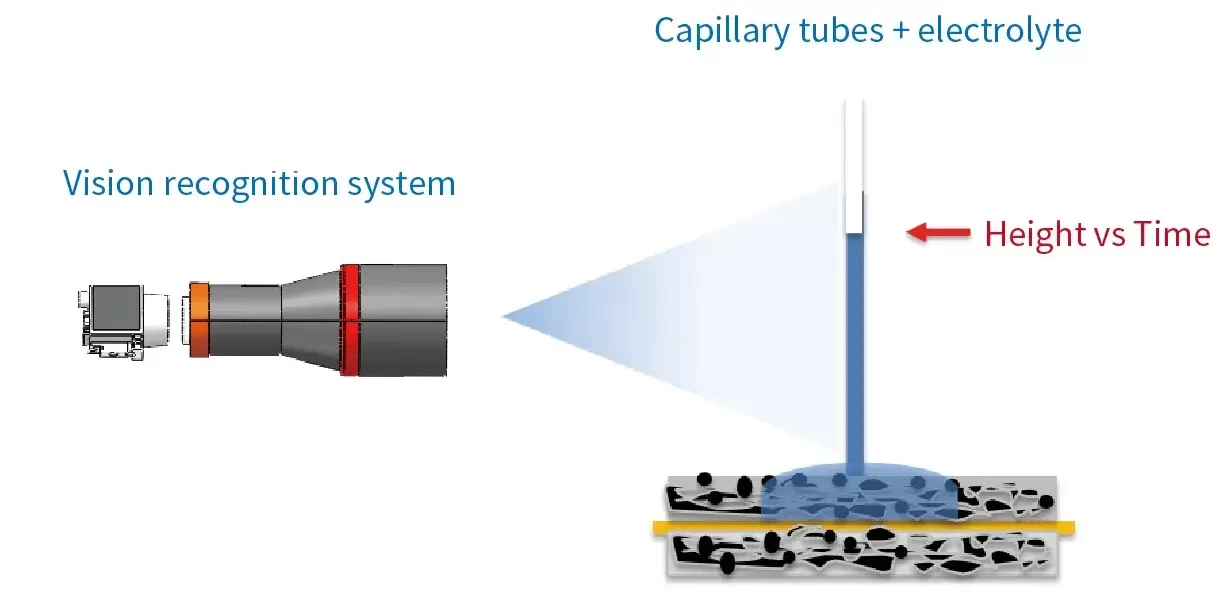

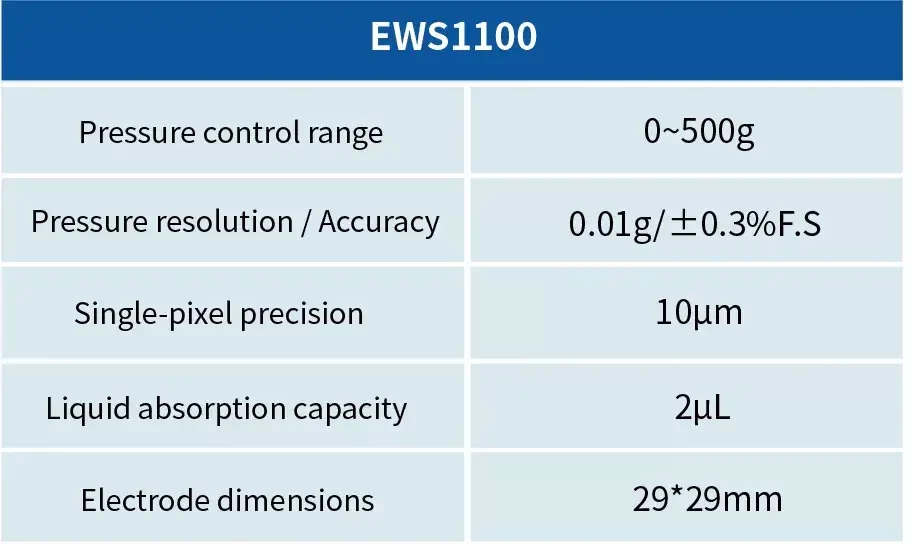

3.1 Capillary Wetting System: EWS Series – Simulation & electrode uniformity

Key Features:

- Equipped with a high-precision vision acquisition system, ensuring stable and efficient test repeatability.

- Enables in-situ real-time characterization of the electrolyte wetting rate for lithium-ion battery anode electrodes.

- Applicable Samples: anode electrode

- The greater the compacticion of the electrode, the lower the porosity, resulting in poorer electrolyte wetting.

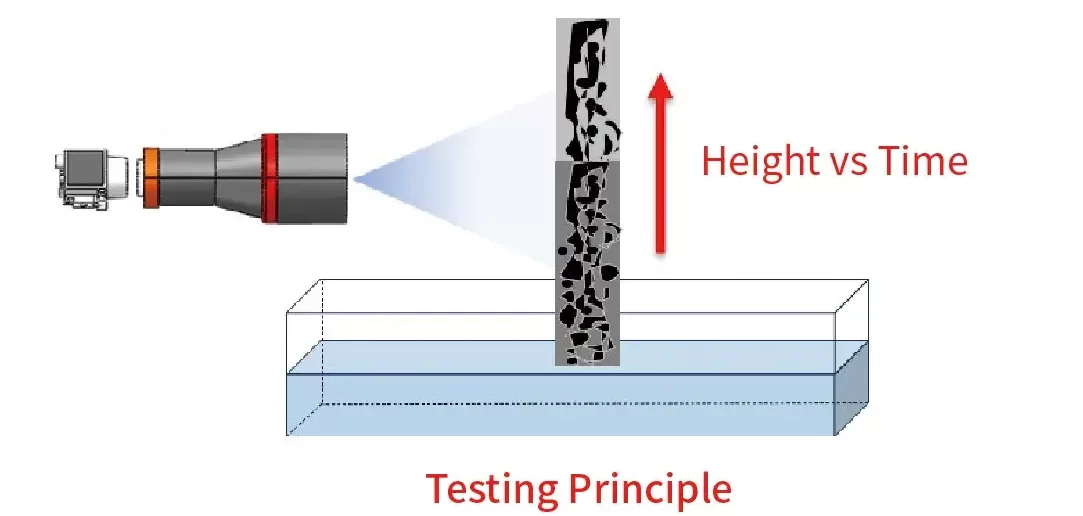

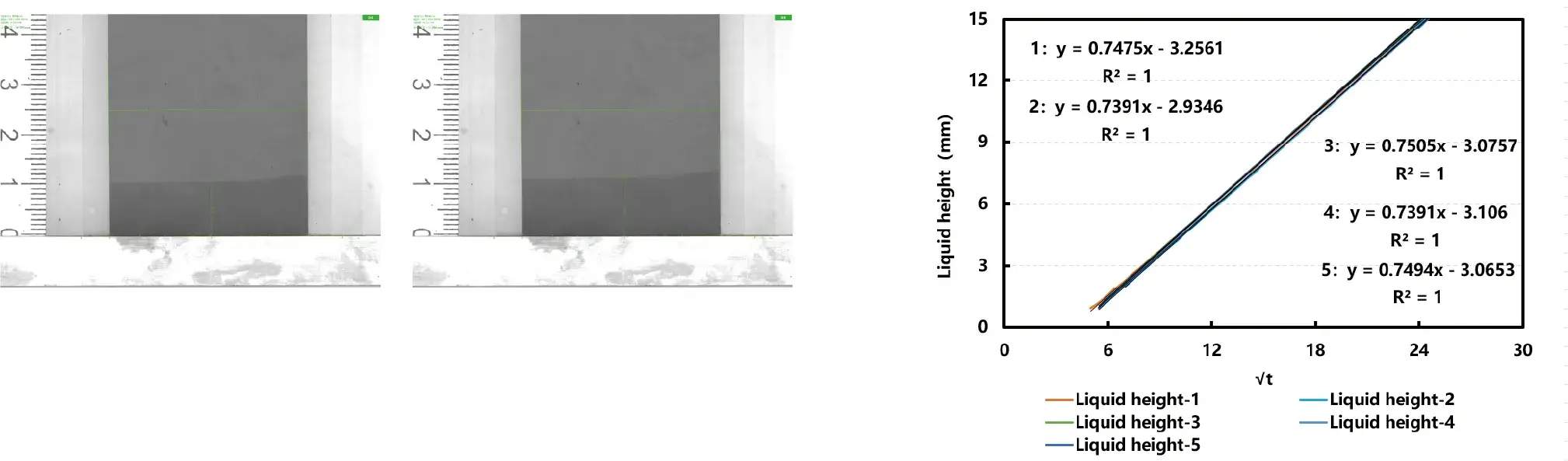

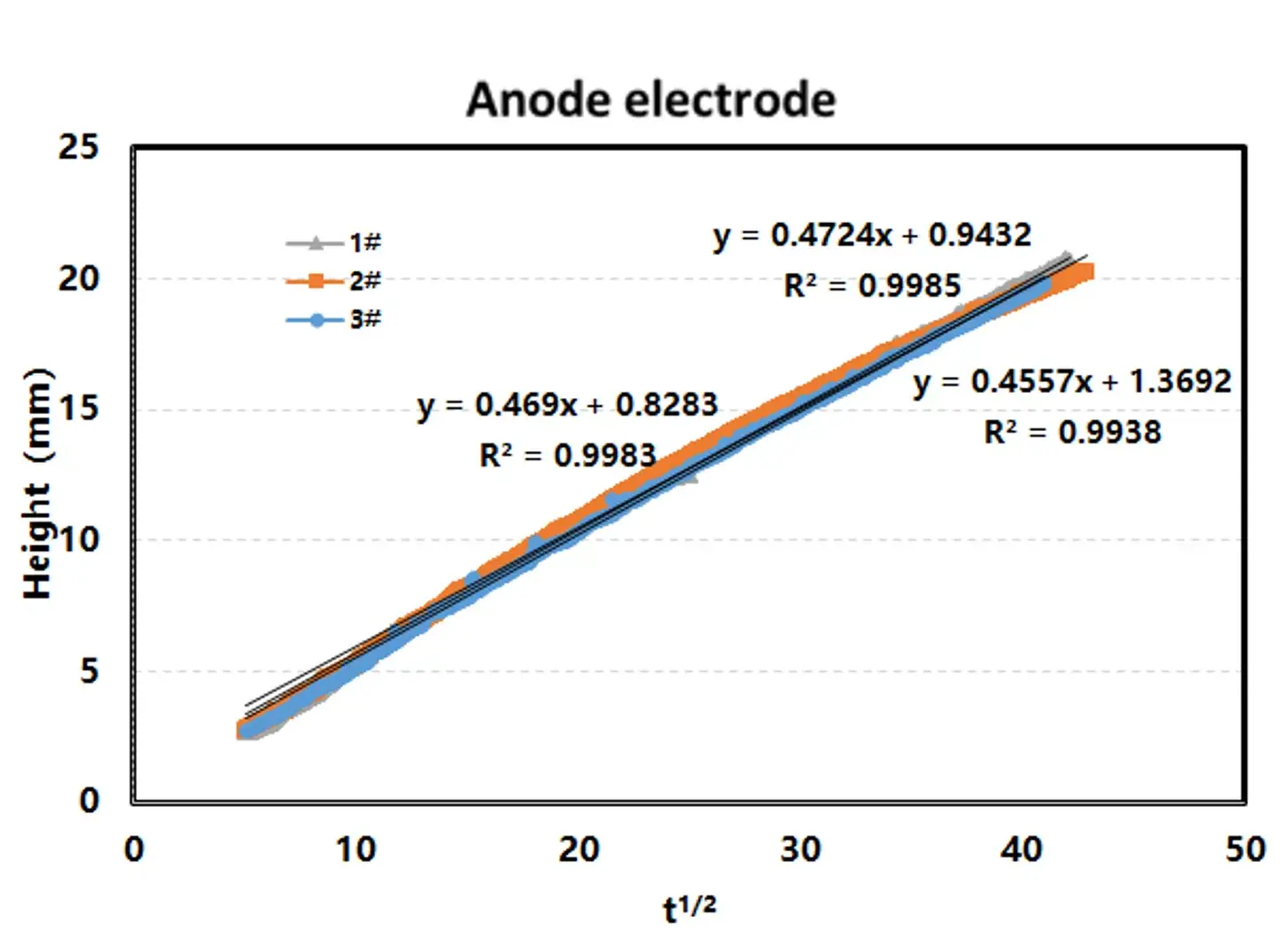

3.2 Height Wetting System: CHT Series – Electrode uniformity & process stability

Key Features:

- Equipped with a high-precision vision acquisition system, ensuring stable and efficient test repeatability.

- Enables in-situ real-time characterization of the electrolyte wetting rate for lithium-ion battery anode electrodes.

- Applicable samples: Anode electrodes

- Supports simultaneous testing of three parallel samples, demonstrating good consistency in electrolyte wetting.

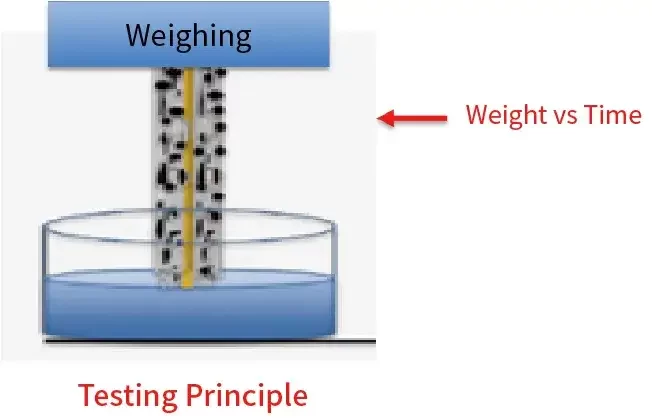

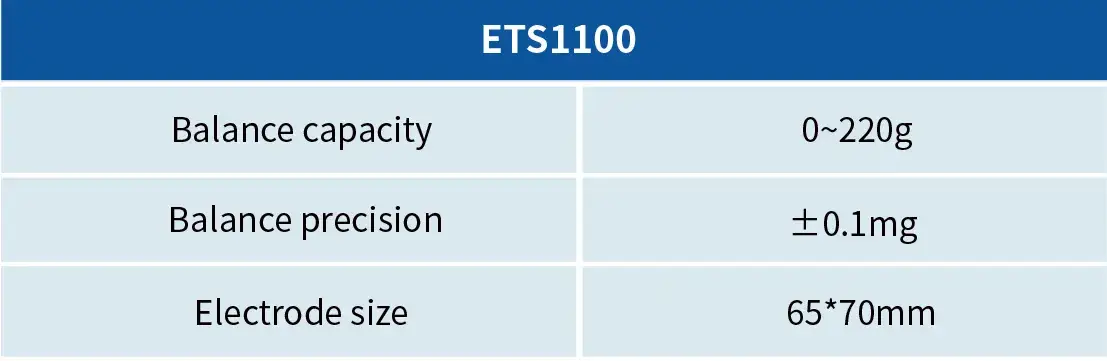

3.3 Weight Wetting System: ETS Series

3.3.1 ETS-1000 – Evaluate Jelly Roll(JR) Wetting Time for Dry Cells

Key Features:

- Equipped with a high-precision vision acquisition system, ensuring stable and efficient test repeatability.

- Enables in-situ real-time characterization of the electrolyte wetting rate for lithium-ion battery anode electrodes.

- Applicable samples: Anode electrodes/Jelly Roll(JR) cells

- Supports simultaneous testing of three parallel samples, demonstrating good consistency in electrolyte wetting.

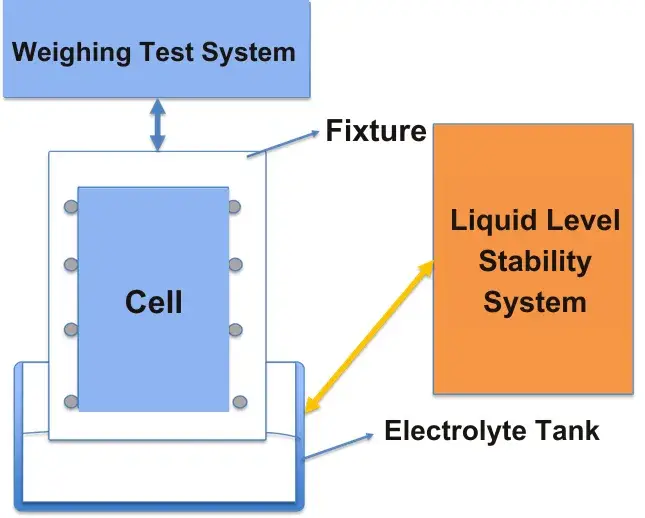

3.3.2 ETS-2000 Dry Cell JR Weight Testing System

Key Technical Features

- Weighing System: Maximum capacity 6 kg, accuracy ±0.1 g, meeting Jelly Roll (JR) test requirements;

- Liquid Level Control: Integrated electrolyte tank level control system (syringe pump + height sensor) to reduce inter-group test errors caused by liquid level fluctuations;

- Pressurized Testing: Added surface pressure fixture (pressure range: 0-0.4 MPa) with pressure film detection system for real-time monitoring of pressure variations during wetting;

- JR Resistance: Expanded channels with an internal resistance meter to externally monitor changes in JR internal resistance during wetting.

Applications

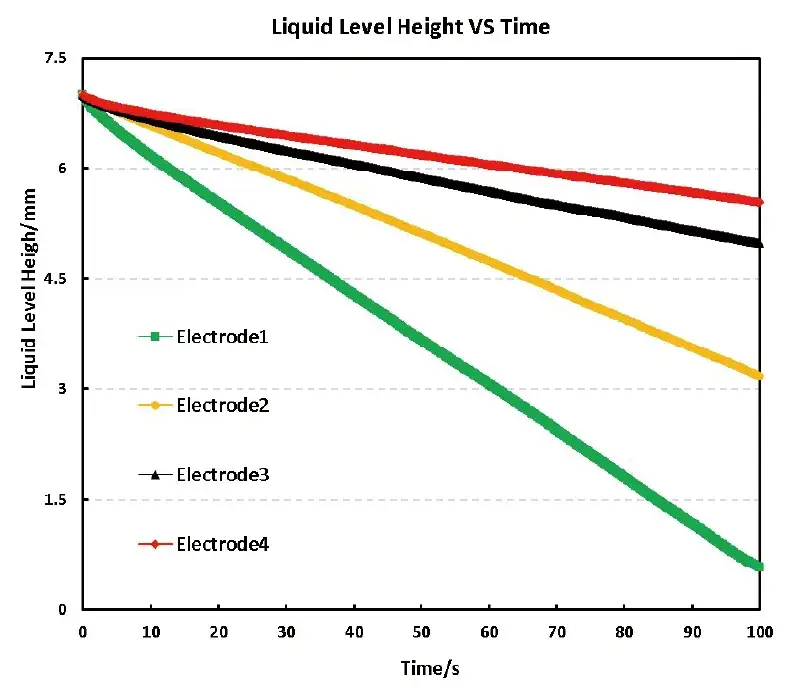

1. Capillary Wetting System-EWS Series

- Four different compaction densities of electrodes: 1 (1.35 g/cm³) < 2 (1.5 g/cm³) < 3 (1.6 g/cm³) < 4 (1.65 g/cm³)

- The greater the density of the electrode, the lower the porosity and the worse the electrolyte wettability.

2. Weight Wetting System-ETS Series

- Trimming three sets of anode electrode from the same batch (65*70mm)

3. Height Wetting System-CHT Series

- The slopes of the 3 tested electrodes are consistent with each other, so is the wetting consistency of their electrolytes.

Video

Specifications

Capillary Wetting System-EWS Series

Weight Wetting System-ETS Series

Height Wetting System-CHT Series